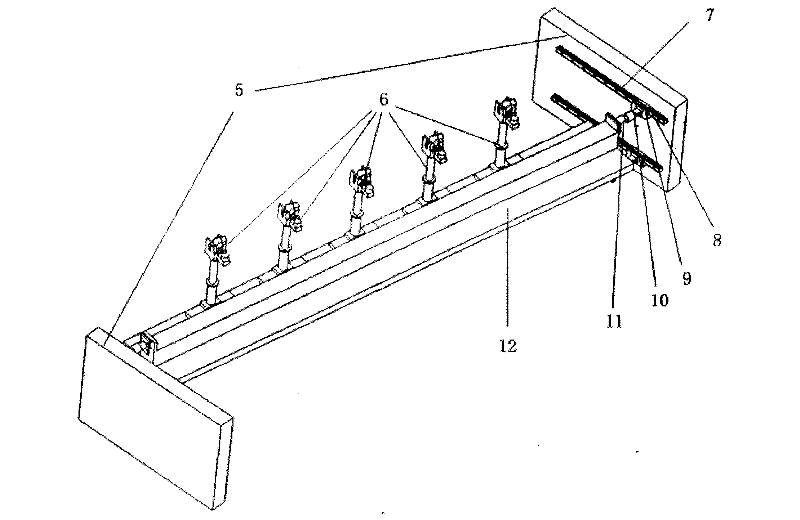

Multipoint flexible positioning method and tool for automatic drilling and riveting assembly of wallboard

An automatic drilling and riveting, flexible positioning technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problem of not completely getting rid of, flexibility and automation are not satisfactory, can not adapt to low cost, high quality and fast response, etc. Problems, to achieve the effect of not easy to pinch, high degree of automation and assembly accuracy, convenient and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

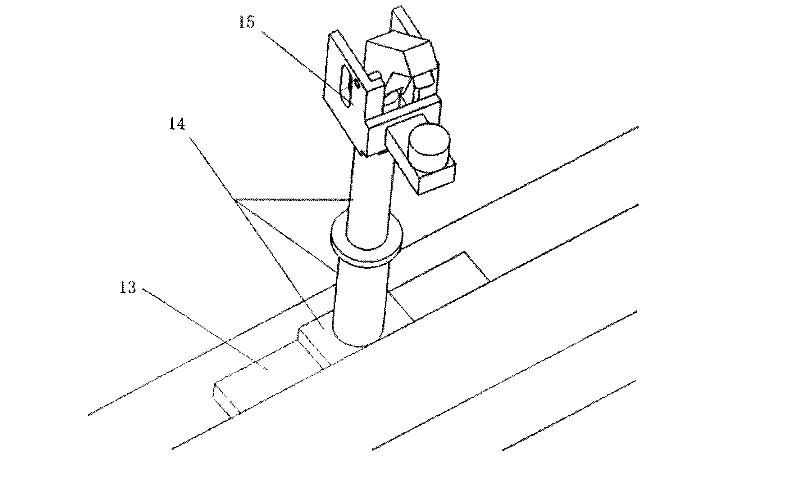

Embodiment Construction

[0031] Method example:

[0032](1) Under the CATIA software environment, read in the 3D model information of the upper left panel of a certain type of wing and the model information of a certain bracket type automatic drilling and riveting system, position the panel model on the model of the automatic drilling and riveting system, and measure Theoretical travel of each degree of freedom of each tooling positioning point, for each stringer, a number of pre-positioning holes are evenly distributed according to the length of the stringer, and several key feature points are selected from the pre-selected positions of the pre-positioning holes to represent its pose respectively, and the key The theoretical coordinates of the feature points represent the theoretical pose of the stringers; for the skin, the pre-positioning holes are arranged according to the positions of the pre-positioning holes of the stringers, and several key feature points are selected from the pre-selected posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com