Single-surface traceless welding method for stainless steel composite panel of elevator

A composite panel, single-sided traceless technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of insufficient bonding strength, stainless steel mirror surface damage, environmental pollution, etc., to save subsequent processing procedures , smooth surface, and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

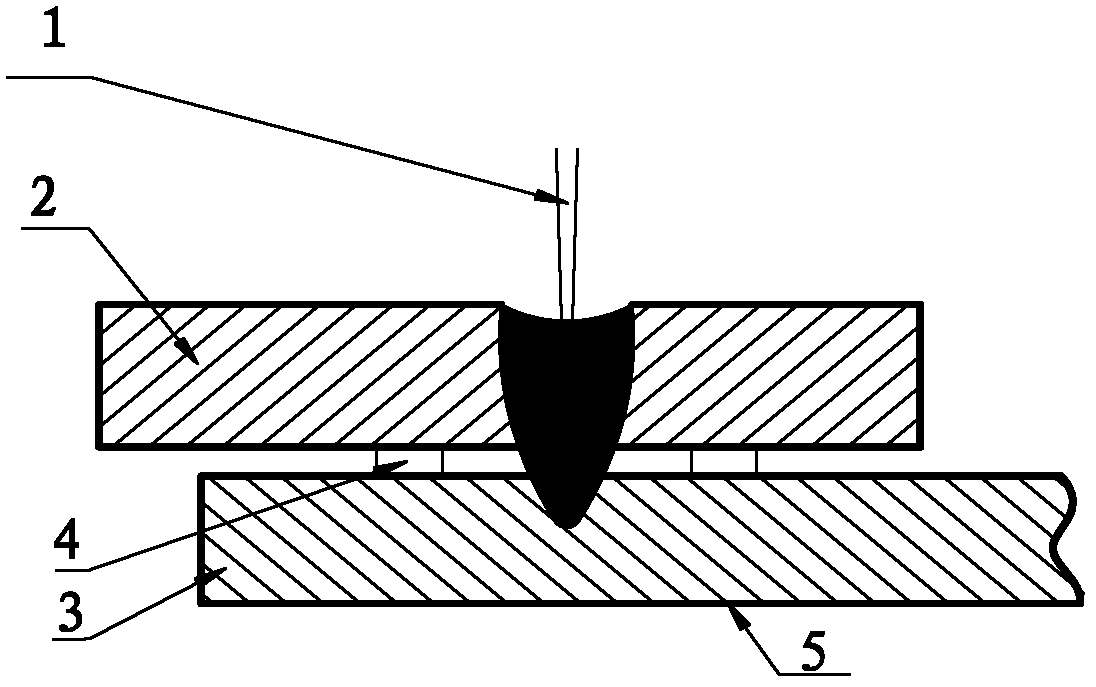

[0034] The welding method used is as figure 1 and figure 2 As shown, the 1.1mm thick Q235 hot-rolled steel plate is used; the stainless steel surface plate is 1.1mm thick AISI 304 brushed stainless steel panel; the length of the spacer = the length of the weld + 20mm, the purpose of being longer than the weld is to facilitate pulling out after welding , Spacer width = 20mm, spacer material is ANSI 304 stainless steel.

[0035] Predetermine the welding position before laser welding, and then clean the workpiece with acetone and rosin water; place two spacers with a thickness of 0.1mm on the stainless steel surface plate, and the two spacers are located on both sides of the place to be welded. Place a hot-rolled steel plate on the surface of the hot-rolled steel plate at 8mm, and install a roller device on the surface of the hot-rolled steel plate to be welded. The roller is provided with a spring that can apply force in the vertical direction. The focusing mirror is fixedly ...

Embodiment 3

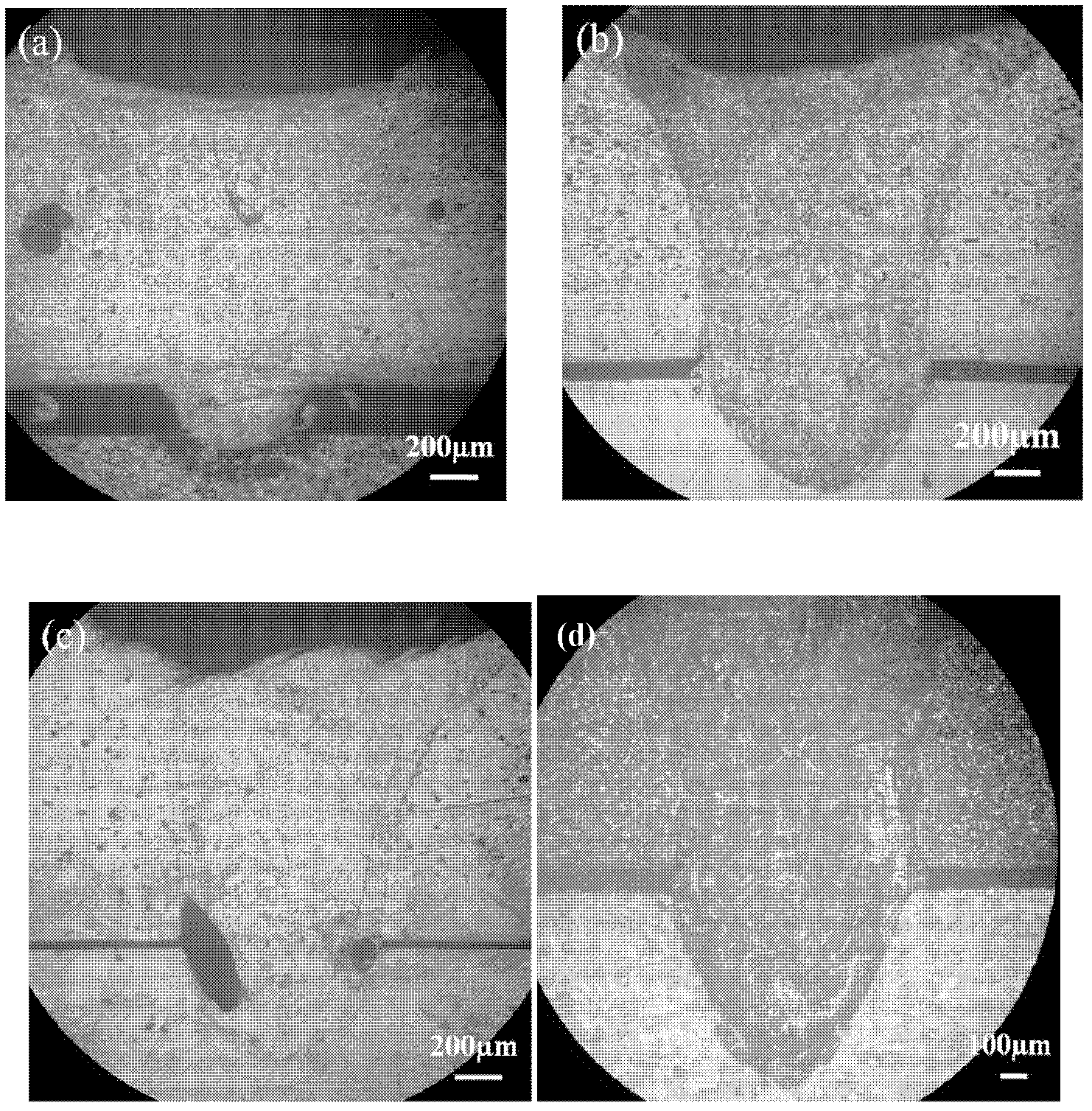

[0043] Change the Q235 hot-rolled steel plate into Q235 cold-rolled steel plate, and the others are the same as in Embodiment 1. After welding, the cross-section of the weld was intercepted and chemically etched (with 10g FeCl 3 +30ml concentrated HCl+120ml aqueous solution as chemical etching agent), obtain sample, observe the morphology of this sample under optical microscope, such as image 3 (d) shown.

[0044] Depend on image 3 (a), 3(b), 3(c), and 3(d) it can be seen that when the thickness of the partition is too large (0.2mm), the depth of the weld on the metal surface plate is very shallow, and the connection strength is not enough; while When the thickness of the partition is too small (0.05mm), the thermal resistance effect is not obvious, the penetration depth is large, and the weld quality is poor. Only when the gap between plates is selected properly (0.1mm), defects such as air holes and cracks hardly appear in the obtained weld, and the quality of the weld ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com