Welding head acceleration device for spot-welding package machine

An acceleration device and packaging machine technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency and slow speed, so as to speed up spot welding speed, improve equipment production efficiency and spot welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

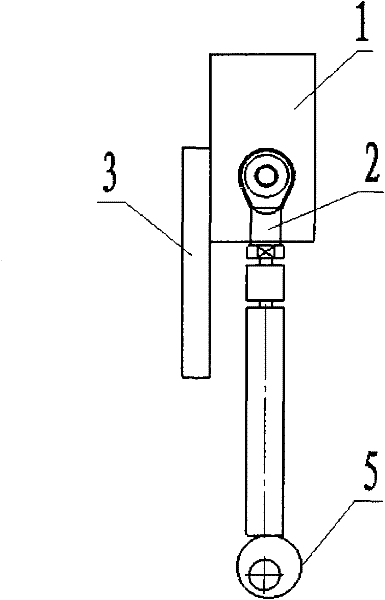

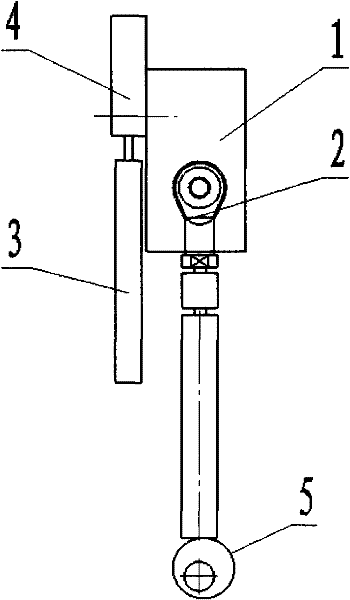

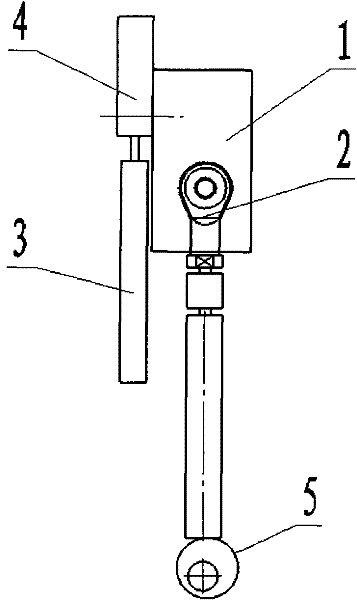

[0010] Install a cylinder (4) at the welding head, the cylinder (4) is fixed on the tie rod fixing block (1), the welding head mechanism (3) is connected with the cylinder (4), and the cylinder (4) pushes the welding head mechanism (3) Fast moving, the cylinder (4) cooperates with the pull rod (2), and works simultaneously with the cam (5) to achieve the purpose of acceleration. When moving, the pressure and stroke of the cylinder (4) are stable, which improves the quality of spot welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com