Method for processing garment lower hem corners for mounting zipper

A treatment method, hem technology, applied in the direction of sewing tools, etc., can solve the problems of fabrics that are easy to be caught, and achieve the effect of neat appearance, smooth sliding up and down, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

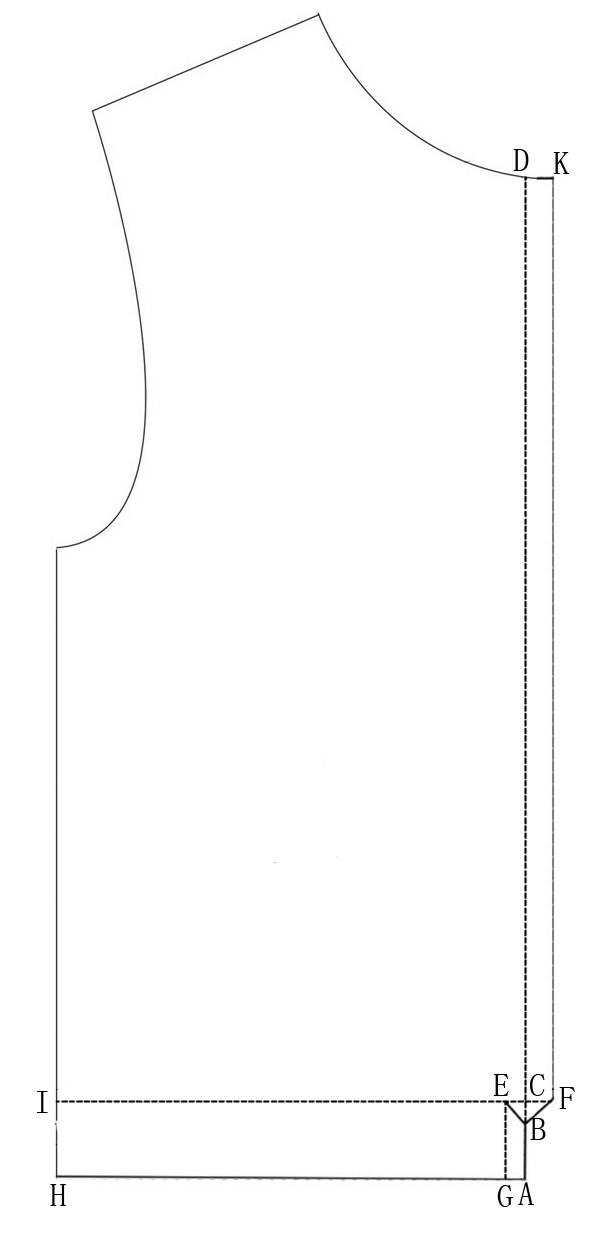

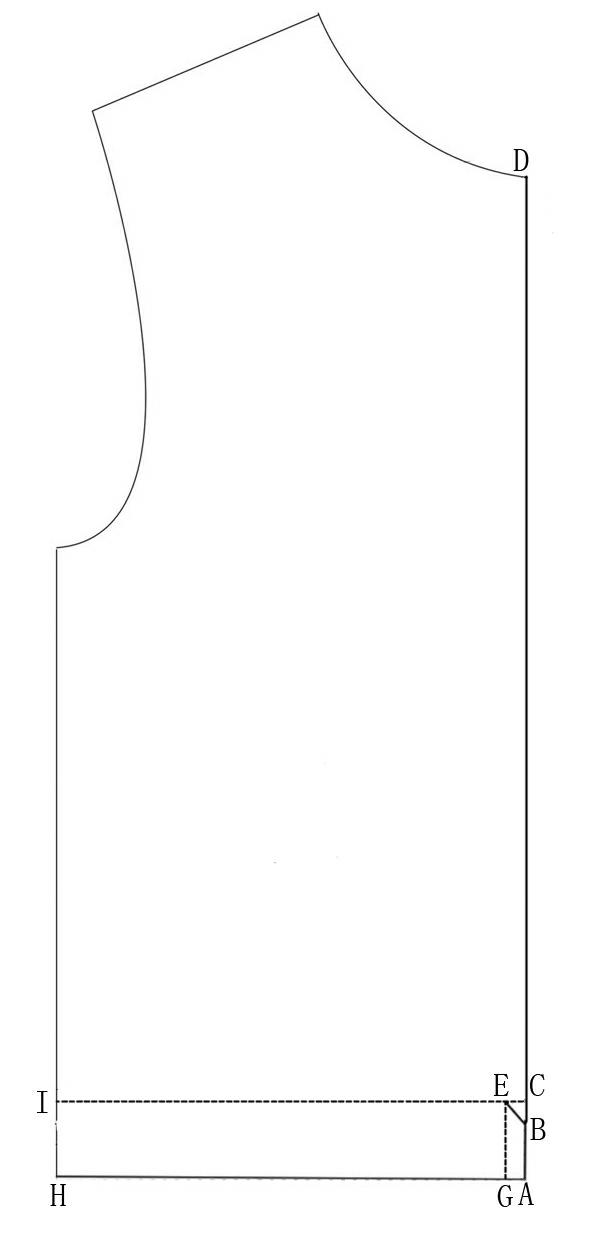

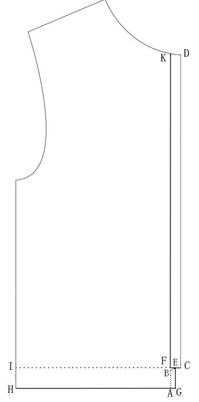

[0014] as attached figure 1 , 2 , shown in 3, 4, the processing method at the hem corner of a kind of upper zipper of the present invention, the processing method at the left front piece of clothing and the right front piece hem corner place is identical, wherein the processing method at the left front piece hem corner place comprises the following steps:

[0015] (1) Draw a line: Pass the point A of the left front hem to make the vertical line AC of the hem. The vertical distance from point A to the cutting line in the center of the left front is 2.0-2.6cm, the height of AC is 2.7-4.7cm, and pass through point C Make the vertical line EF of AC, point F is located on the cutting line of the center of the left front piece, the length of CE is 0.8-1.3cm, take point B on AC, make the length of BC 1.2-1.5cm, connect BE and BF; pass E Point the vertical line EG for the hem;

[0016] (2) Cutting: Cut off the OABF fabric along the AB and BF lines, and cut an opening along the BE; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com