Transverse control arm of a motor vehicle

A technology of transverse linkages and vehicles, applied in the direction of vehicle components, cantilever mounted on pivots, elastic suspensions, etc., can solve the problems of journal joint damage, impossible to eliminate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

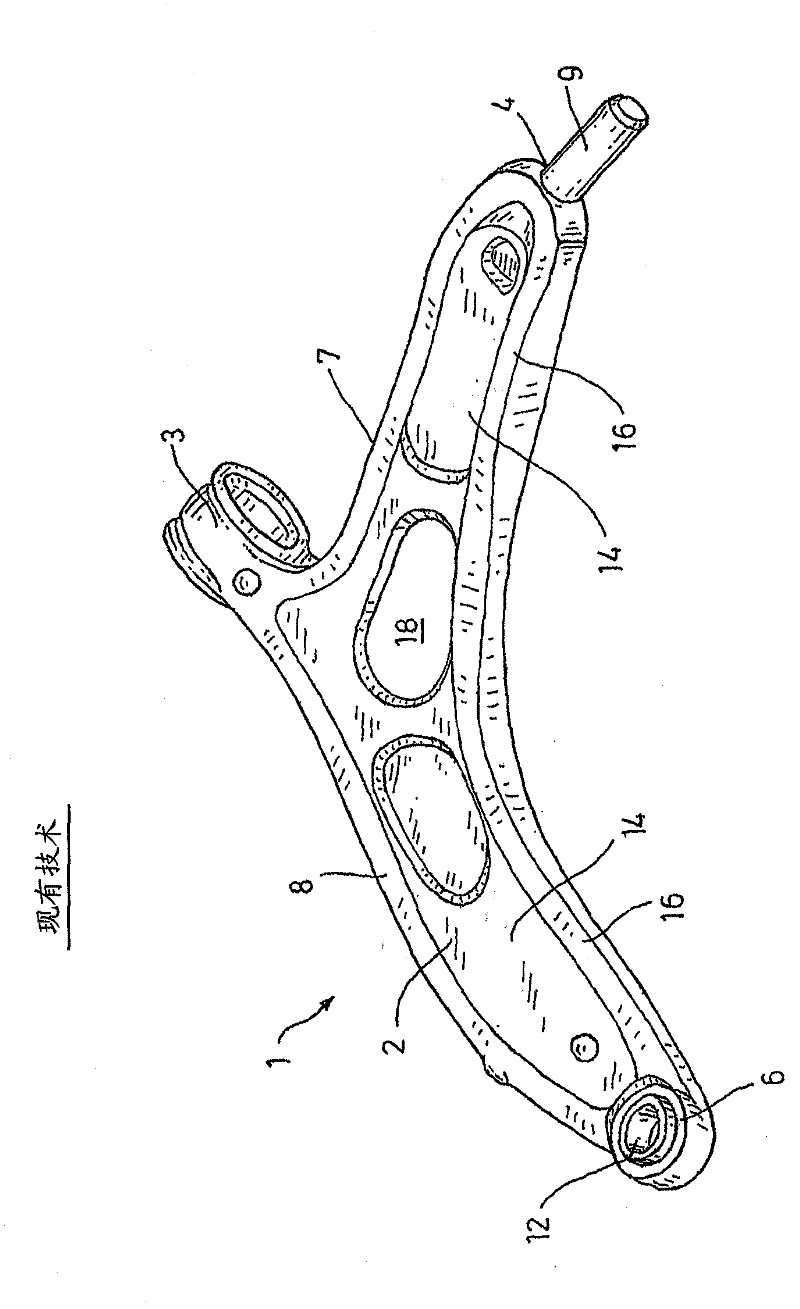

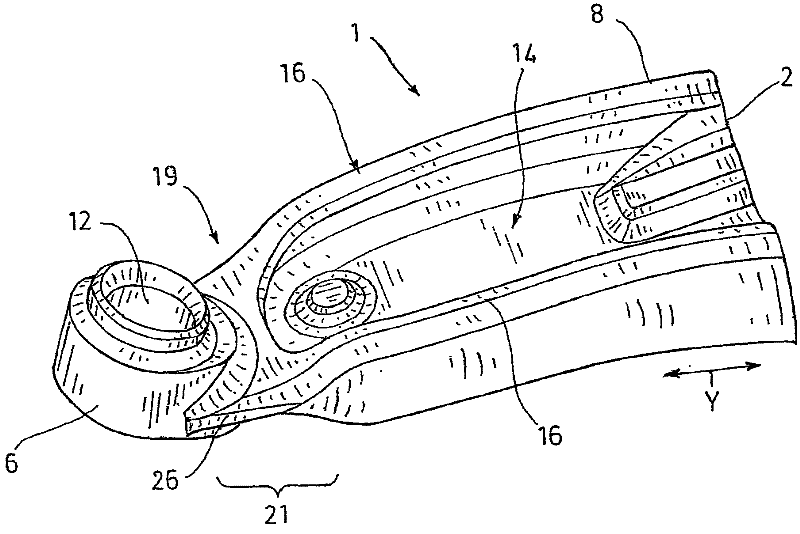

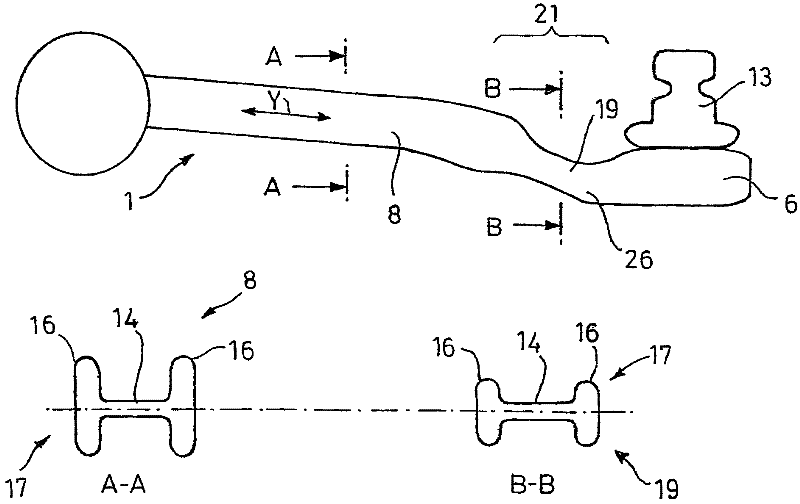

[0052] In the various figures, identical parts are always provided with the same reference signs, for which reason they are also generally described only once.

[0053] figure 1 A transverse link 1 according to the prior art is shown. The transverse link 1 has a main body 2 with a first fixing area 3 and a second fixing area 4 for pivotal attachment to a vehicle frame element (not shown, eg a subframe). The transverse link 1 also has a further fixing area, namely a third fixing area 6 , for pivotal attachment to a hub carrier (not shown). The main body 2 with the frame wings 7 and the wheel wings 8 is substantially L-shaped. The first fastening area 3 and the second fastening area 4 are arranged on a frame wing 7 . The first fastening area 3 is realized, for example, as a sleeve, the second fastening area 4 is realized, for example, by a bearing element 11 (see Figure 4 ) around the journal 9.

[0054] The third fastening area 6 is arranged on the wheel wing 8 and is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com