Decolorizing method for gentamicin sulfate production

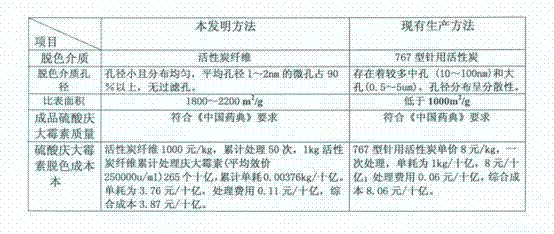

A technology of gentamicin sulfate and gentamicin, applied in the field of medicine and chemical industry, can solve the problems of decolorization cost of polluted environment, high residence, large amount of activated carbon, etc., and achieve reduction of decolorization production cost, large economic and social benefits, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

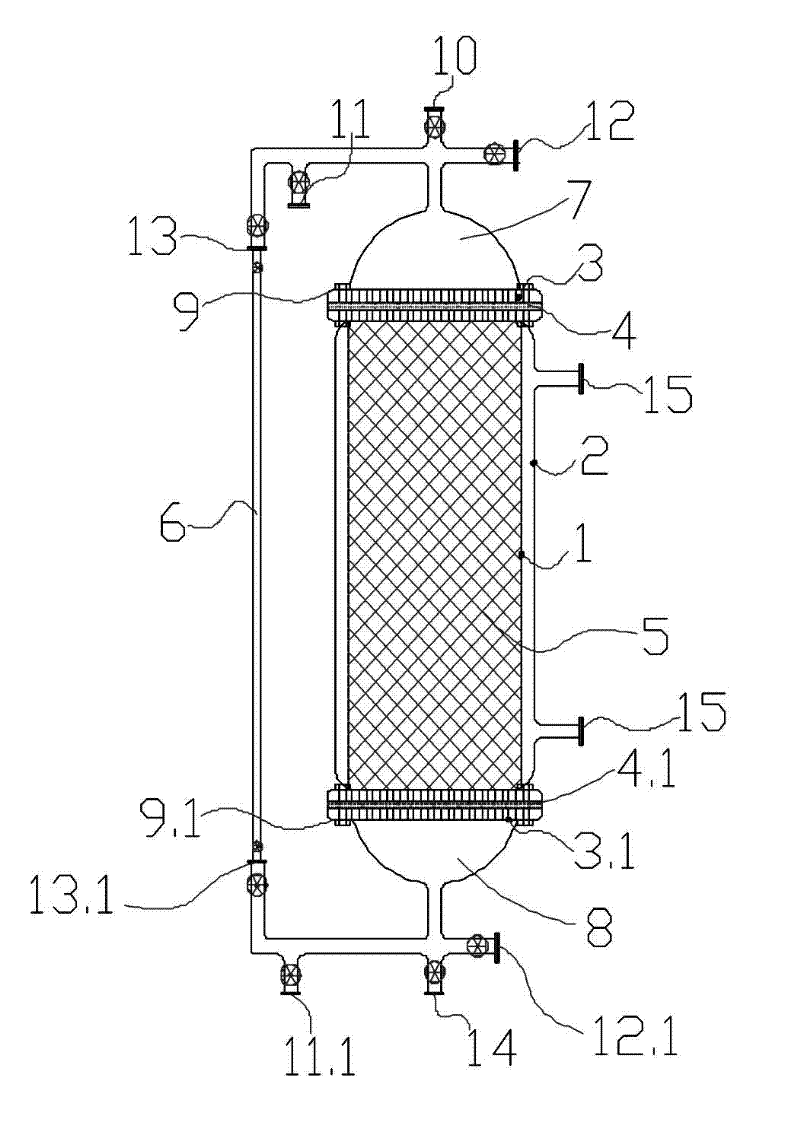

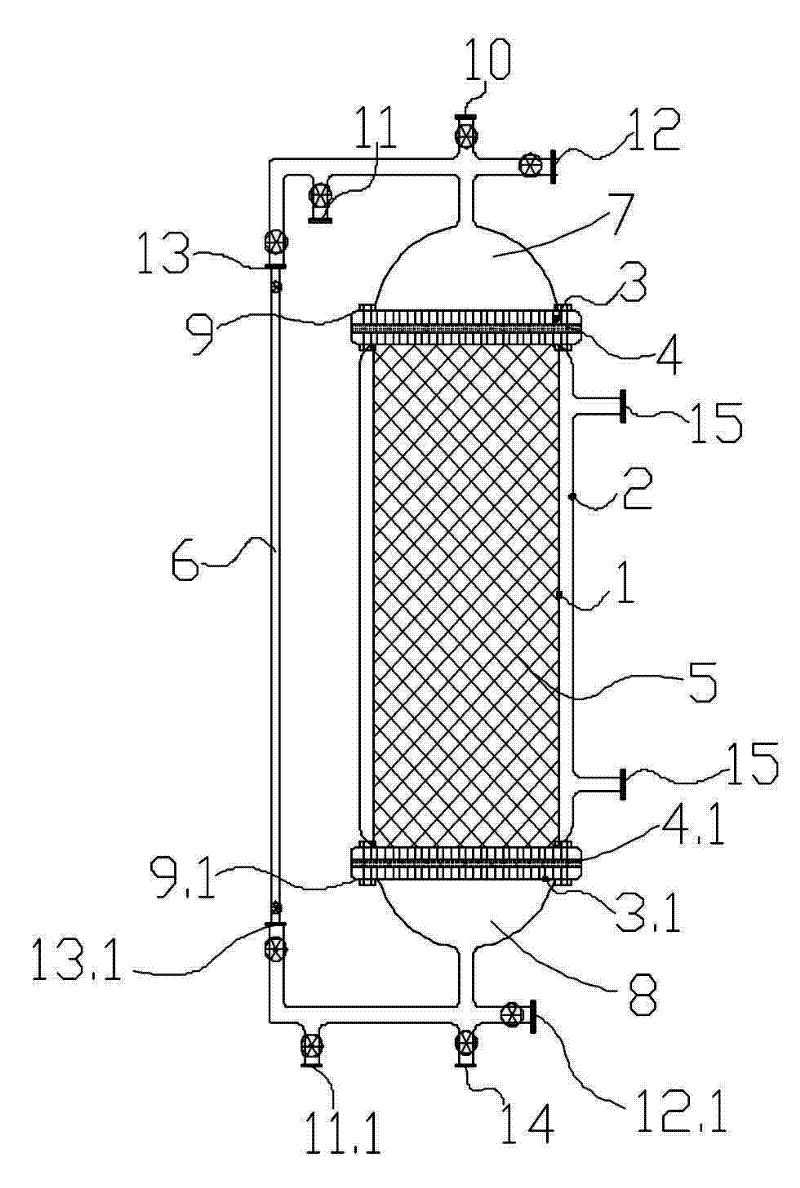

[0024] Gentamicin sulfate production decolorization method of the present invention is to adopt cold filtration in conjunction with the method for the decolorization of activated carbon fiber adsorption tower in the production of gentamicin sulfate, and this method is that gentamicin salt solution is filtered out macromolecular protein through low temperature After mixing with macromolecular pigments, an active carbon fiber tower is used for heating and adsorption decolorization, and the decolorized gentamicin sulfate solution is spray-dried to obtain finished gentamicin sulfate.

[0025] For this reason, Gentamicin Sulfate of the present invention produces decolorization method, specifically comprises the following steps:

[0026] ①. Cool the gentamicin salt solution to 3℃~7℃, filter it with a filter with a pore size of 16~30um, the titer of the filtrate is 200000~300000u / ml, and the transmittance of the filtrate at 460nm is 10%~20% between;

[0027] ②. Press the above filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com