Cement slump-retaining grinding aid as well as preparation method and application thereof

A grinding aid and cement technology, applied in the field of cement slump-preserving grinding aids, can solve problems such as concrete slump loss, and achieve the effects of improving performance, reducing losses, and overcoming single performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

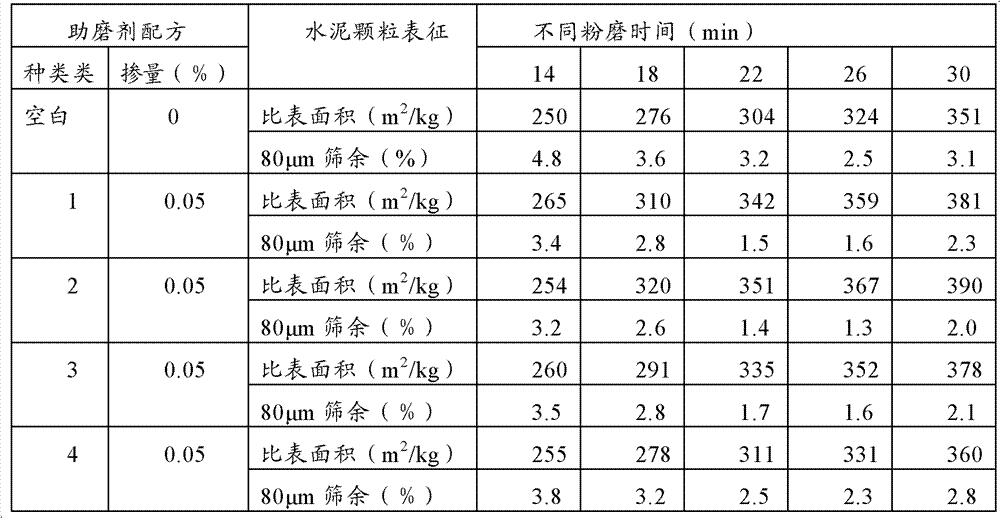

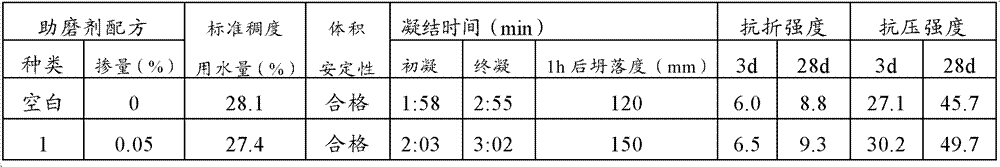

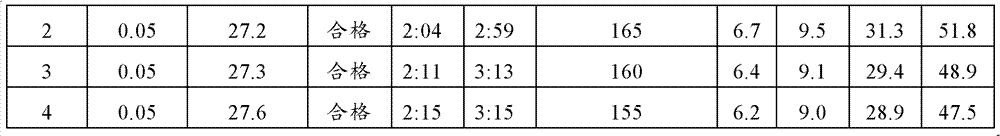

Embodiment 1

[0024] Example 1: Prepare the following raw materials in mass percentages: 4 g of sodium tripolyphosphate, 21 g of sodium hexametaphosphate, 10 g of ethylene glycol, 2.0 g of the above-mentioned sulfamate-based water reducer containing carboxylic acid groups, and 63 g of tap water. Mix sodium tripolyphosphate and water and stir evenly, when sodium tripolyphosphate is completely dissolved, add sodium hexametaphosphate evenly while stirring; when the sodium hexametaphosphate is completely dissolved, add ethylene glycol and sulfamic acid group containing carboxylic acid group Salt-based superplasticizer, stirred evenly to obtain No. 1 slump-preserving grinding aid.

Embodiment 2

[0025] Embodiment 2: prepare the raw material of following mass percentage: 6.0g sodium tripolyphosphate, 19.0g sodium hexametaphosphate, 8.0g ethylene glycol, 1.0g sulfamate water reducing agent containing carboxylic acid group and 66.0g water. The preparation method is the same as in Example 1 to obtain No. 2 slump-retaining grinding aid.

Embodiment 3

[0026] Embodiment 3: prepare the raw material of following mass percentage: 7.0g sodium tripolyphosphate, 10.0g sodium hexametaphosphate, 4.0g ethylene glycol, 0.5g sulfamate water reducing agent containing carboxylic acid group and 78.5g water. The preparation method is the same as in Example 1 to obtain No. 3 slump-retaining grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com