Continuous shot-blasting cleaner

A technology of shot blasting machine and shot blaster, which is applied in the direction of abrasive jetting machine tools, abrasives, metal processing equipment, etc., and can solve the problems of low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

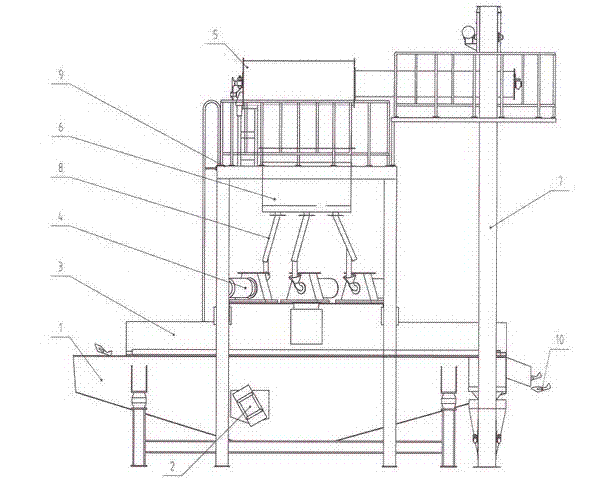

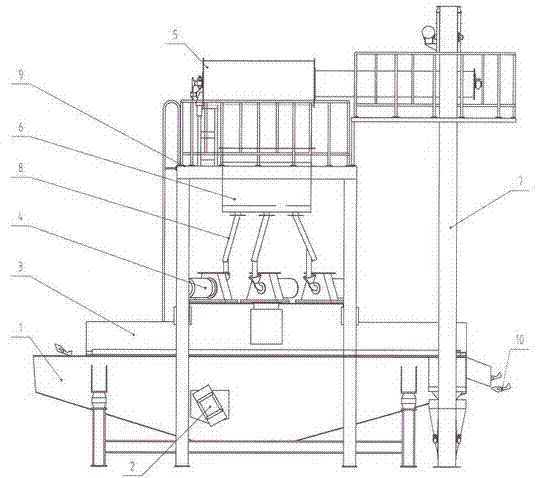

[0018] like figure 1 A kind of continuous shot blasting cleaning machine shown, comprises shock bed 1, shot blasting chamber 3, shot blaster 4, sand shot storehouse 6, hoist 7 and sand shot separator 5; The scale plate machine is connected, and the castings directly enter the continuous shot blasting machine for surface cleaning without any turnover transportation, and there is no need to turn over the workpiece. With the aid of elastic outriggers fixed installation, the vibration bed conveys the castings forward through vibration, the top surface is provided with a grid-shaped bearing surface, the lower surface of the bearing surface is provided with a transversely inclined inclined surface, and the bottom of the inclined surface is provided with a sand shot outlet; The shot blasting chamber 3 is located above the shock bed 1, and its lower end opening is sealed and docked with the upper opening of the shock bed 1; the top of the shot blast chamber 3 is provided with at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com