Method for eliminating longitudinal stripes on surface of cast rolling stock for ultra-thin aluminium foil

A longitudinal stripe, ultra-thin aluminum foil technology, applied in metal rolling and other directions, can solve the problems of delayed production cycle, broken aluminum foil, increased production cost, etc., and achieves the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Concrete implementation steps of the present invention are as follows:

[0016] 1. Casting nozzle pretreatment

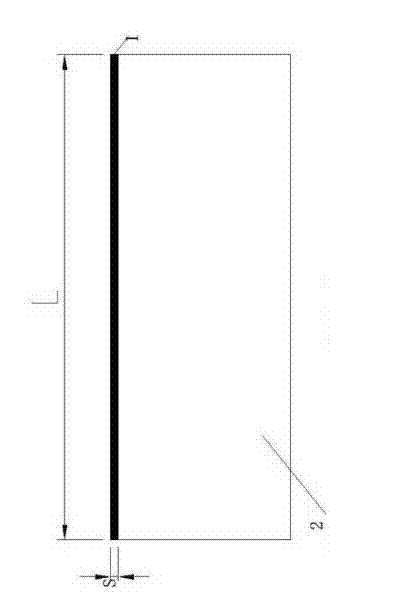

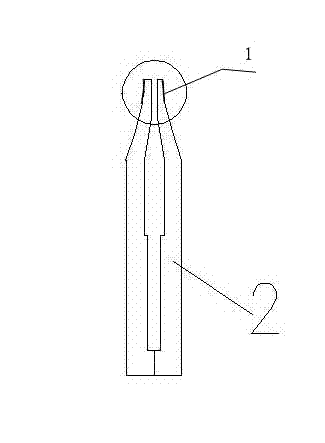

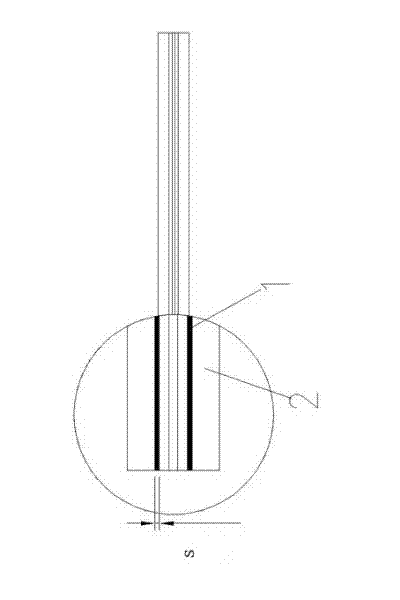

[0017] The casting nozzle used to produce ultra-thin aluminum foil is flat. On both sides of the outer wall of the lip of the casting nozzle, use high temperature resistant structural adhesive TS812 to paste graphite with the same length as the length L of the flat and wide casting nozzle, with a width of 15mm and a thickness of 0.5mm. Paper, to increase the flexible contact between the lip of the casting nozzle and the casting roll, reduce the wear probability of the lip during the production process and on-line processing of stripes, or reduce the probability of longitudinal stripes on the surface of the casting billet caused by damage to the lip.

[0018] 2. Online processing of vertical stripes

[0019] During the production process, on the corresponding casting roll where the longitudinal stripes appear on the surface of the casting billet, use high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com