Valved assembly for metering plants of liquid products

A technology of liquid products and valve components, applied in the direction of mechanical equipment, valve details, multi-way valves, etc., can solve the problems of large size, difficult removal, etc., and achieve the effect of reducing width and convenience advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

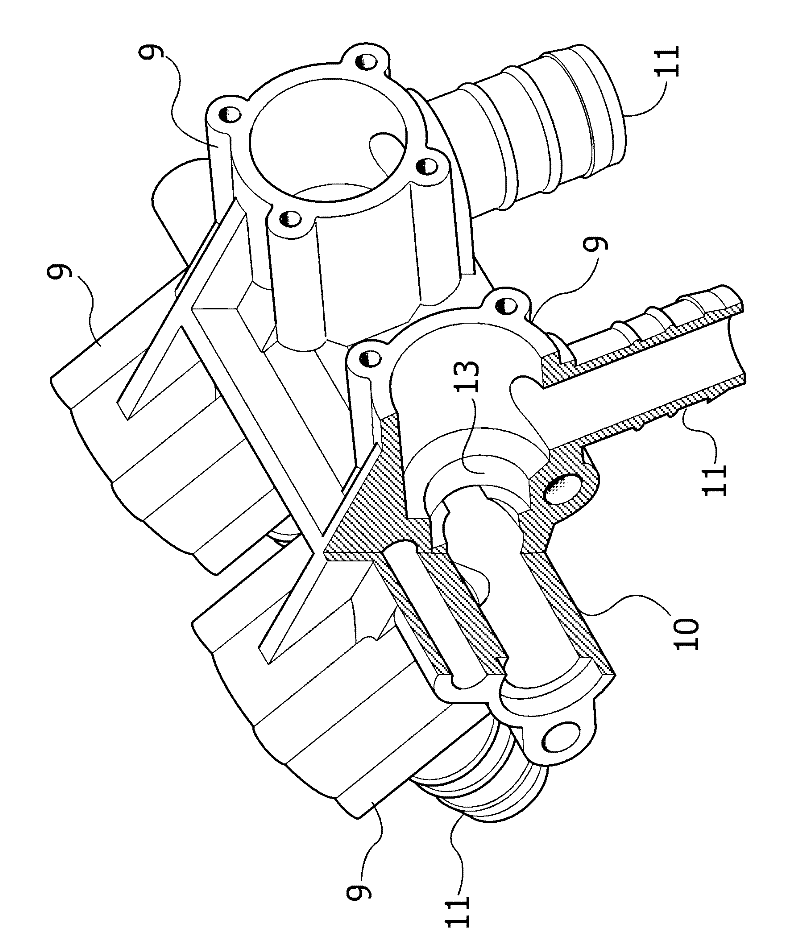

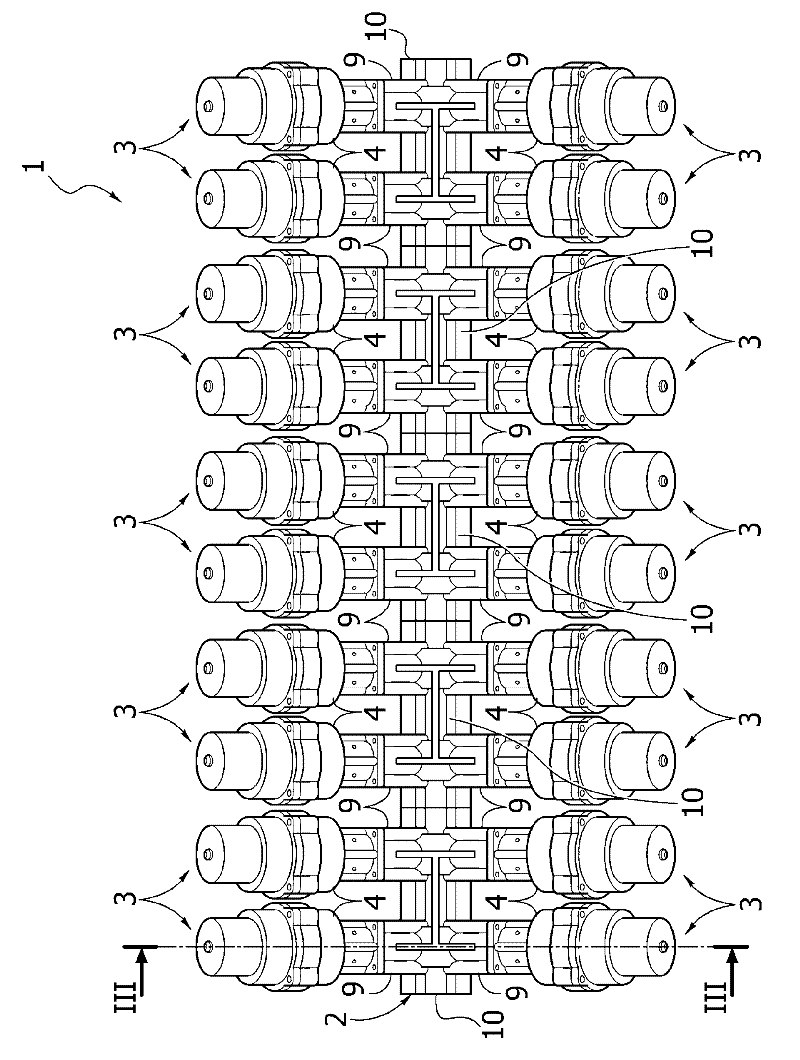

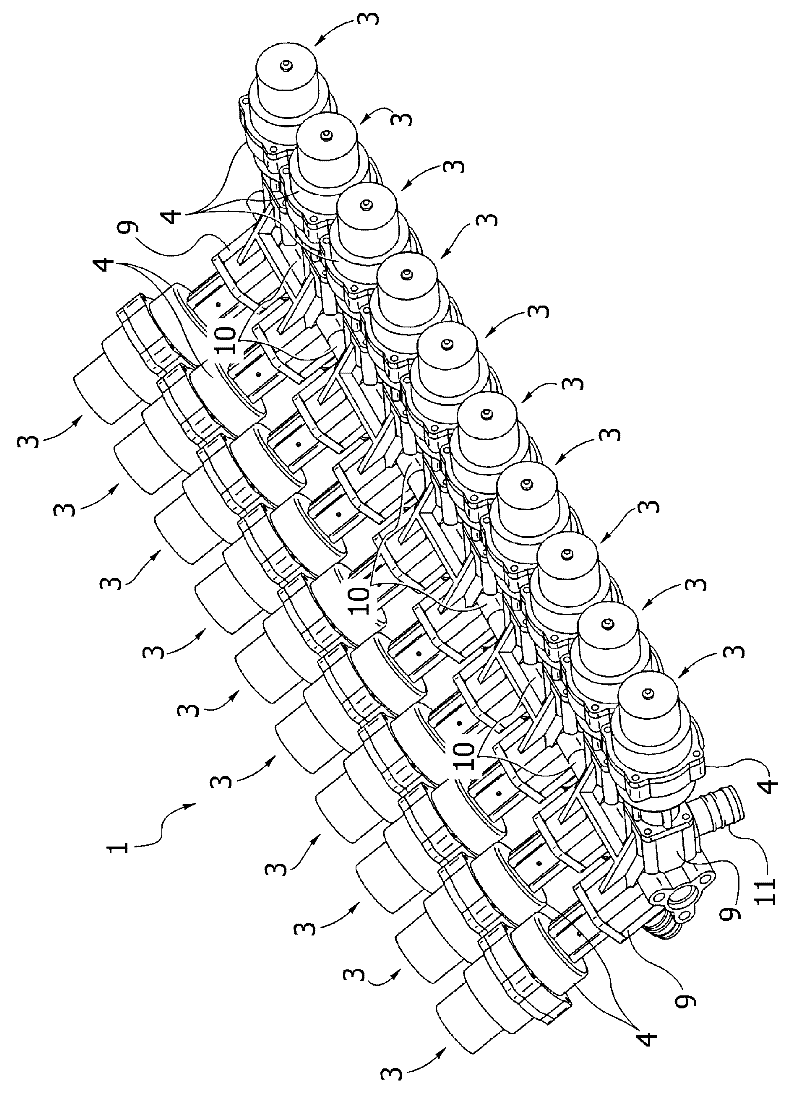

[0021] The figures show an example of an embodiment of a valve assembly according to the invention designed for use in a device for metering liquid products for the treatment and dyeing of fabrics. It will be appreciated that the valve assembly can also be advantageously applied to installations for metering different liquid products, for example in the chemical and cosmetic industry, in the paint industry, etc.

[0022] The valve assembly generally designated with reference numeral 1 is pre-set in a known manner, ie connected at the inlet to a plurality of storage units for liquid products which are usually fed to the respective Assign lines to assign to the equipment used. A measuring device is operatively associated to the distribution line, usually consisting of a flow meter of conventional type, which in turn is connected to an electronic processing and control unit controlling the operation of the valve assembly 1 .

[0023] In general, the valve assembly 1 comprises a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com