Transmission

A technology of transmission and internal teeth, applied in clutches, mechanical drive clutches, intermeshing clutches, etc., can solve problems such as negative shift quality, and achieve the effect of increasing the degree of freedom of inclination and reducing the axial friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

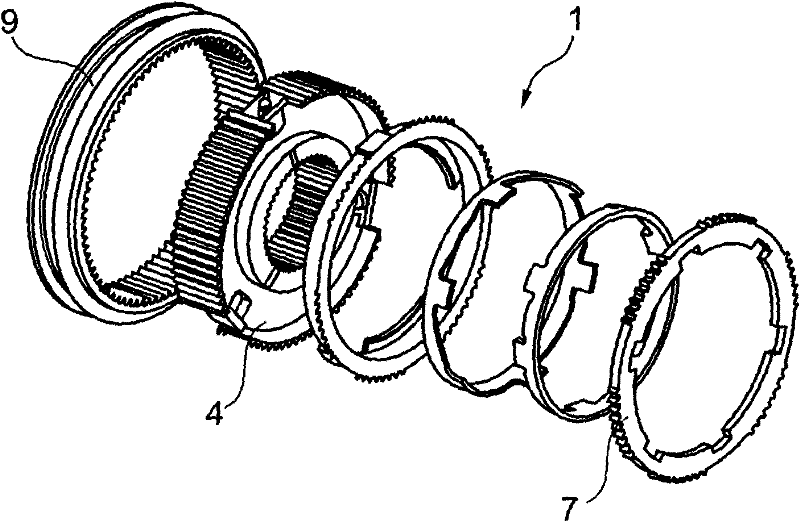

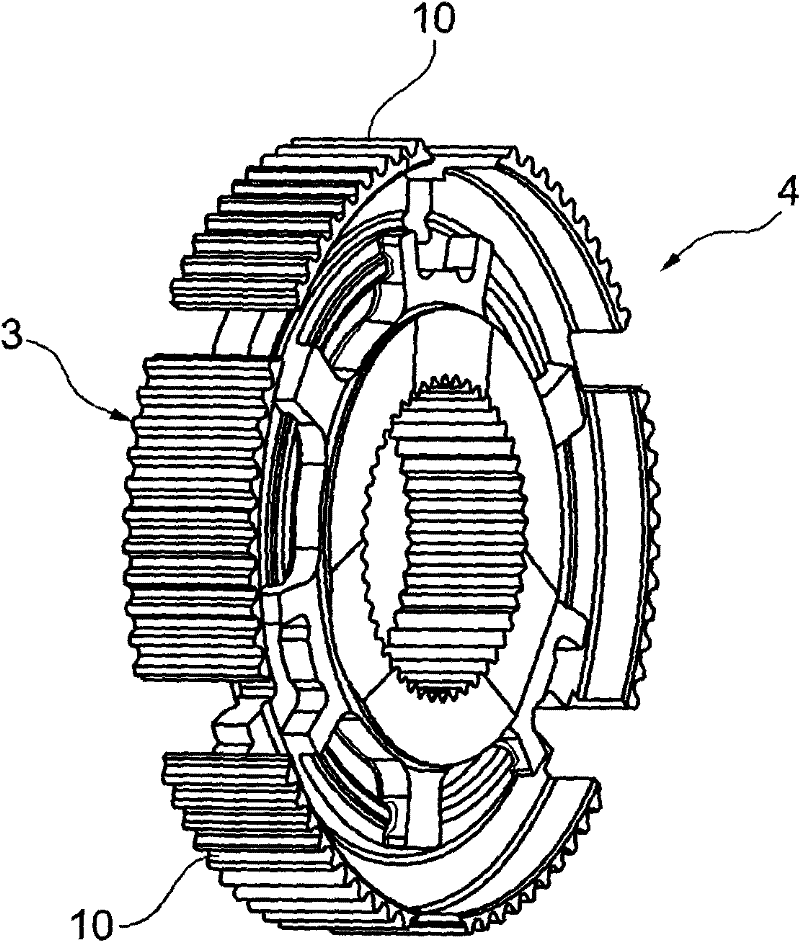

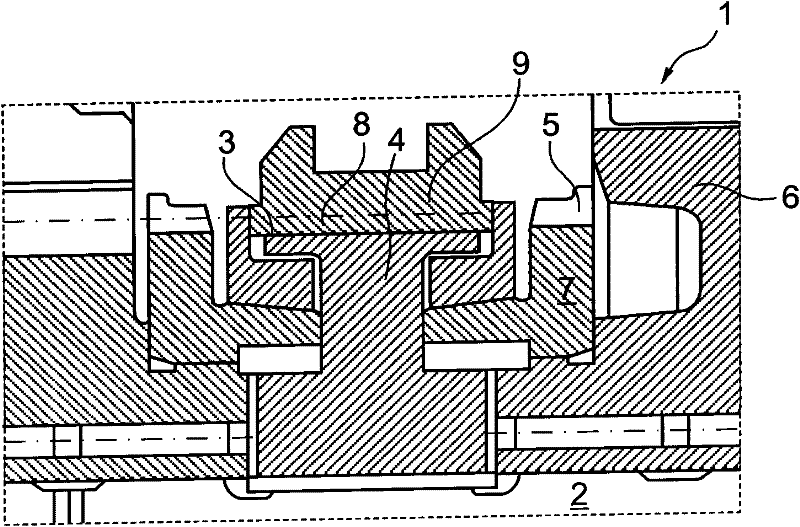

[0019] according to figure 1 and image 3 The transmission 1 according to the invention has at least one shaft 2 on which a guide sleeve 4 with a first external toothing 3 is arranged in a rotationally fixed manner. Also arranged on the shaft 2 is a coupling element 7 with a second external toothing 5 . The second external tooth structure 5 can also be arranged directly on the idler gear 6 . Furthermore, the transmission 1 according to the invention has a sliding sleeve 9 which is displaceable in the axial direction of the shaft 2 and has an internal toothing 8 , wherein the sliding sleeve 9 can be connected in a decoupled position to a It is set between a coupled position in which the internal toothing 8 is not operatively connected to the second external toothing 5 and a coupled position in which the internal toothing 8 meshes with the second external toothing 5 . according to image 3 , where the decoupled position is shown. According to the invention, the inner toothi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com