Spindle structure with torsion regulation

A shaft structure and torque technology, applied in the direction of pivot connection, etc., can solve the problems of different forward and reverse torques, increase of manufacturer's production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

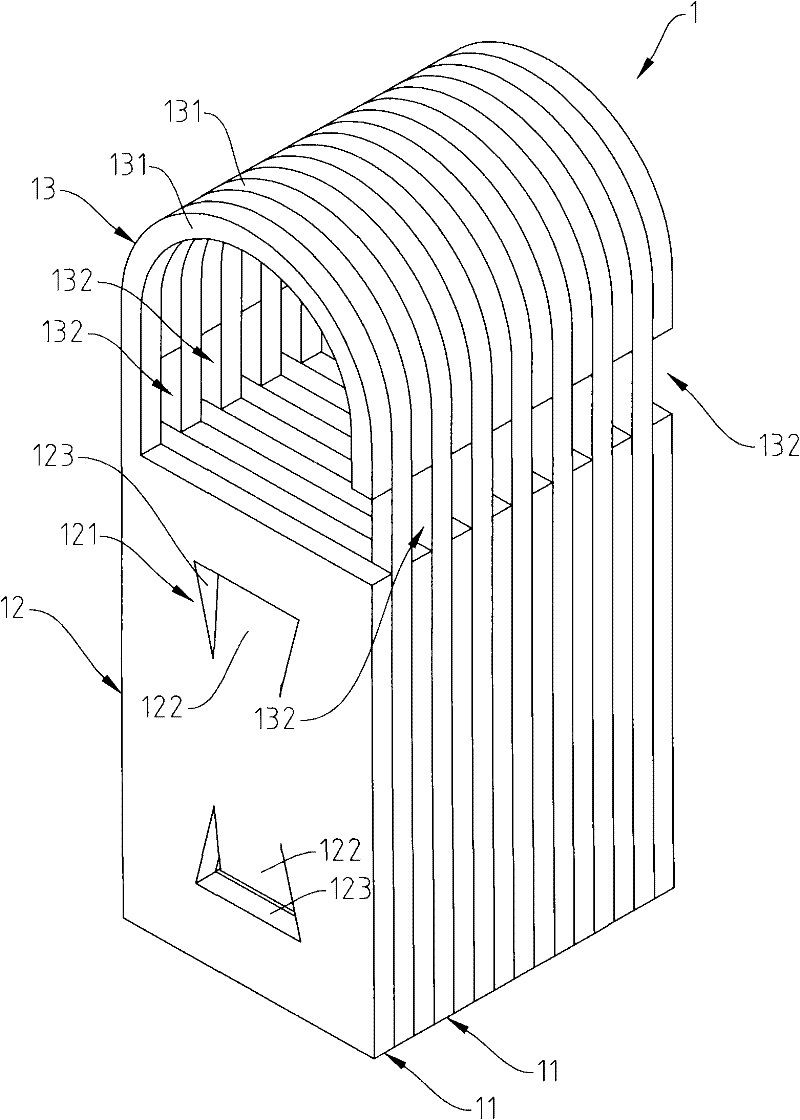

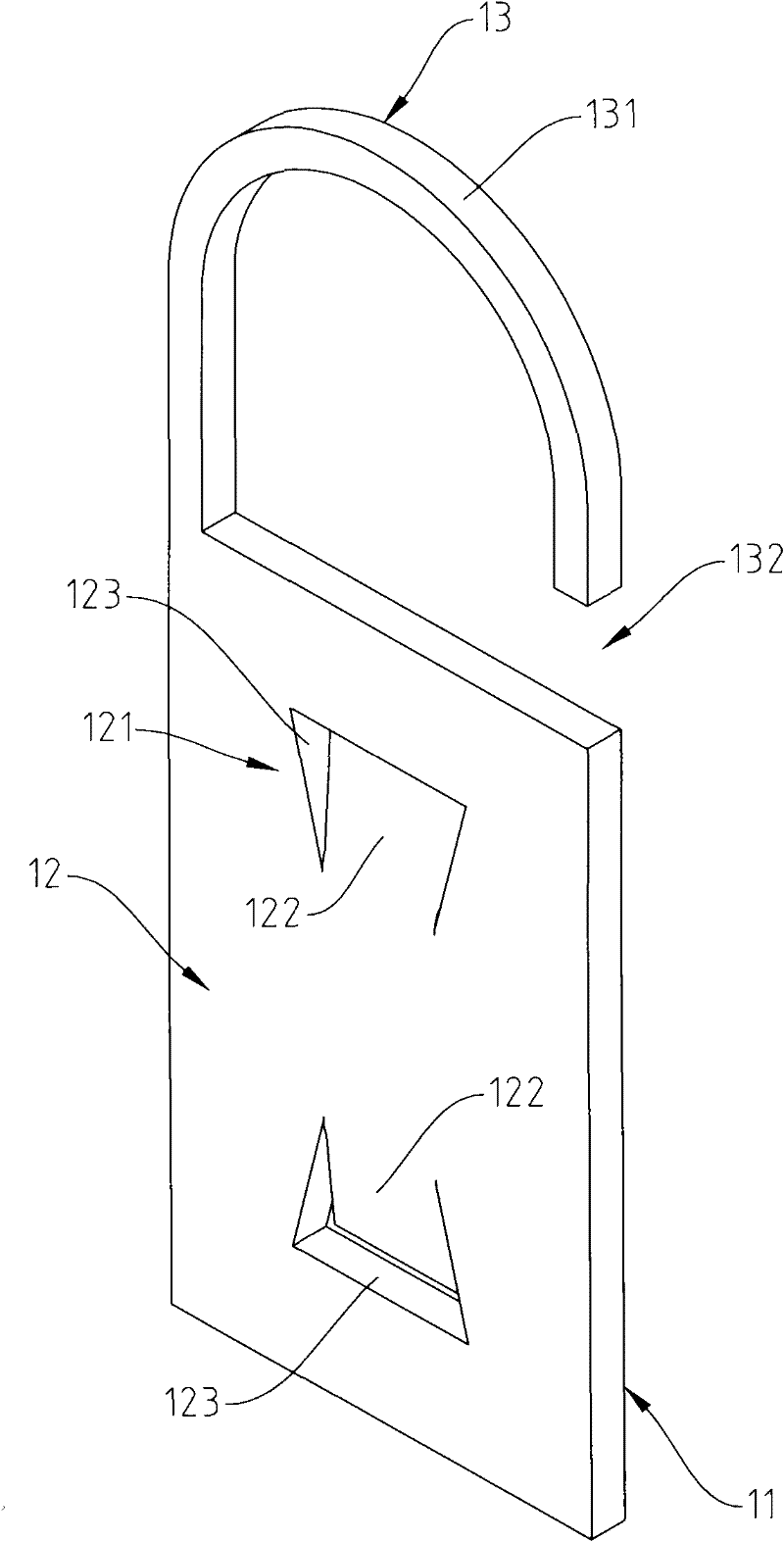

[0020] see figure 1 and figure 2 As shown, it can be clearly seen from the figure that the rotating shaft of the present invention is provided with a female shaft 1, and the female shaft 1 is composed of a plurality of integrally formed sheet bodies 11 joined together (such as figure 1 As shown), each piece 11 has a base 12, and the surface of the base 12 is cut with a retaining part 121, so that the retaining part 121 is formed with a retaining piece 122 and a retaining groove 123, and one side of the base 12 is provided with a shaft cylinder 13, and the shaft tube part 13 extends from one end of the base part 12 to the other end with a shaft tube piece 131, and a slot 132 is formed at the end of the shaft tube piece 131 and the base part 12, so that when a plurality of pieces 11 are connected in parallel to form a female When the axis is 1, the retaining piece 122 of the sheet 11 is positioned in the retaining groove 123 of the adjacent sheet 11 , and the slots 132 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com