A kind of lithium carbon composite material and preparation method thereof

A carbon composite material and lithium powder technology, used in metal processing equipment, electrodes for primary batteries, non-aqueous electrolyte batteries, etc., can solve the problem of increasing the cost of metal lithium raw materials, the processing cost of negative electrodes, the difficulty in improving product quality, and the extremely high temperature and humidity control requirements. Advanced problems, to achieve the effect of good strength, lower production energy consumption cost, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

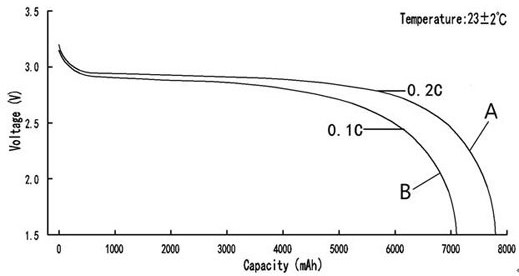

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0024] The invention provides a preparation method of a lithium-carbon composite material, comprising the following steps:

[0025] S1. Preparation of a micron lithium powder mixed solution: metal lithium is dispersed by liquid phase buoyancy in an organic solvent to obtain a micron lithium powder mixed solution.

[0026] S2, adjusting the solid content of the lithium powder: the micron lithium powder mixed solution in step S1 is left still, and a part of the organic solvent in the micron lithium powder mixed solution is discharged, so that the solid content of the lithium powder in the mixed solution is adjusted. to 25% to 35%.

[0027] S3. Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com