Purification equipment and treatment process for tail gas from acrylonitrile absorption tower

A technology of purification equipment and absorption tower, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as increased emissions, and achieve the best effect of reducing emissions and reducing N2O

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

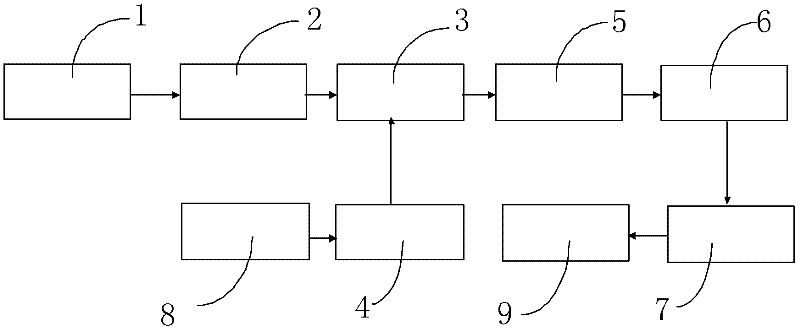

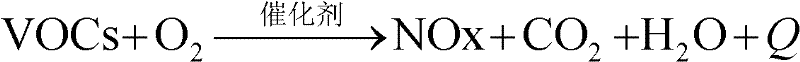

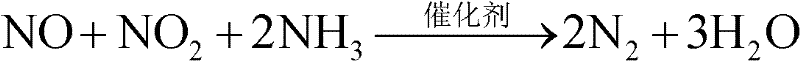

[0033] After the tail gas from the absorption tower passes through the gas-liquid separator 1, it is first preheated by the gas / gas heat exchanger 2, and the temperature rises to 180°C. During the process of flowing to the catalytic reactor 3, fresh air is supplemented by the oxygen supplement fan 4 (Insufficient oxygen content in the original tail gas), the inlet temperature is lowered to 150°C and enters the catalytic reactor 3 for catalytic oxidation reaction, VOCs and CO react with oxygen to generate NOx, H 2 O and CO 2 . Install an external heat exchanger 2 in the middle of the reactor to reduce the temperature of the tail gas and the bed layer, so as to prevent the catalyst from being too high to sinter and deactivate and reduce NO X generation. In the actual process, for the convenience of operation and control, the catalytic reactor is divided into two sections, and the intermediate heat exchanger removes the reaction heat from the front-stage reactor to reduce the o...

Embodiment 2

[0035] The equipment and process are the same as in Example 1, the inlet temperature of the catalytic reactor is about 160°C, the outlet temperature of the catalytic reactor is about 200°C, the removal efficiency of carbon monoxide in the treated exhaust gas reaches 99.7%, and the removal efficiency of non-methane total hydrocarbons reaches 98.2%. After testing, the contents of harmful volatile organic compounds such as carbon monoxide, nitrogen oxides and non-methane total hydrocarbons in the purified tail gas are shown in Table 2.

Embodiment 3

[0037] The equipment and process are the same as in Example 1. The inlet temperature of the catalytic reactor is about 170°C, and the outlet temperature of the catalytic reactor is about 180°C. The removal efficiency of carbon monoxide in the treated exhaust gas reaches 99.6%, and the removal efficiency of non-methane total hydrocarbons reaches 98.0%. After testing, the contents of harmful volatile organic compounds such as carbon monoxide, nitrogen oxides and non-methane total hydrocarbons in the purified tail gas are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com