Filter chamber pressure-bearing open-and-close component for filtering element of flexible tube squeezer

A technology of filter elements and presses, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of large thickness and size, cost reduction, inconsistent strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The filter element of the present invention will be further described below in conjunction with the accompanying drawings.

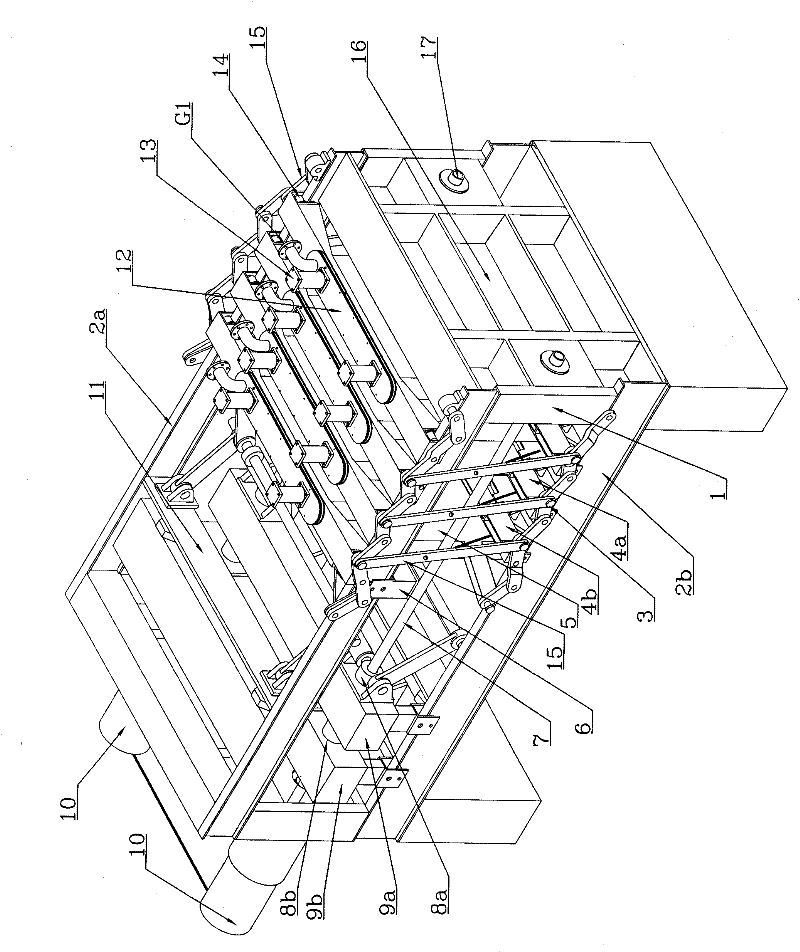

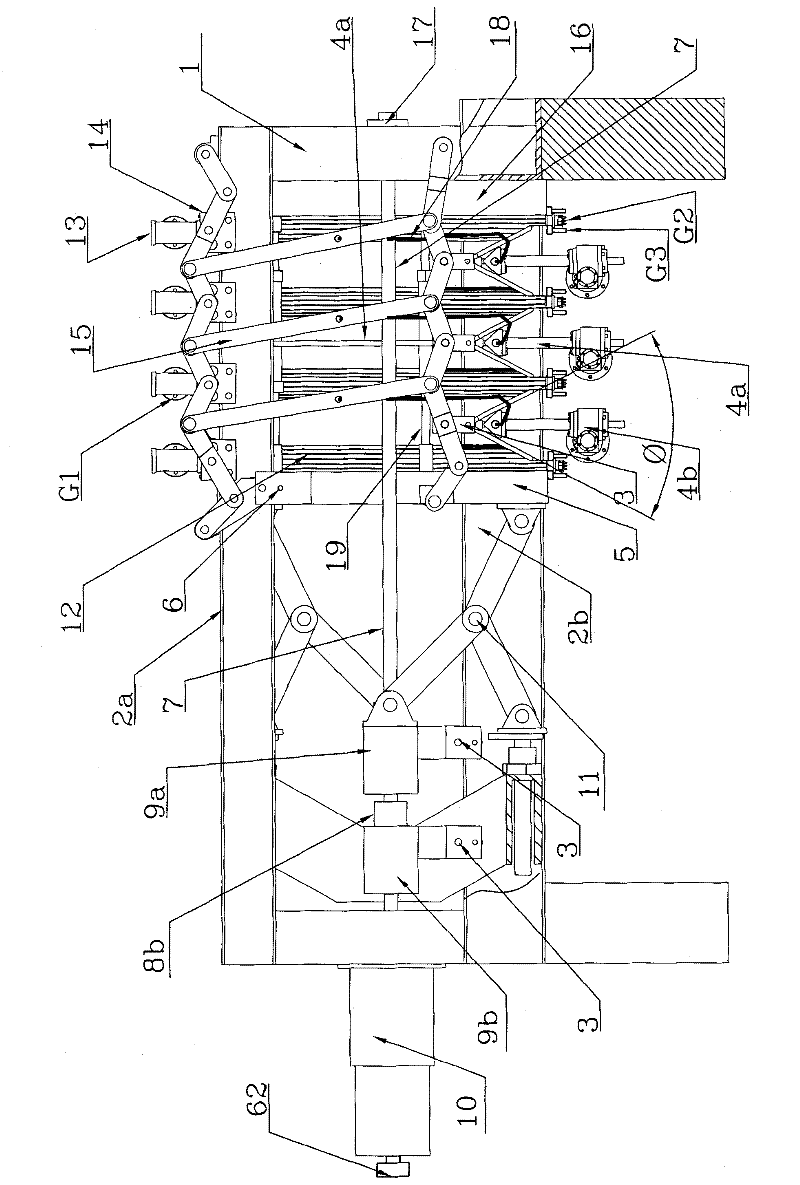

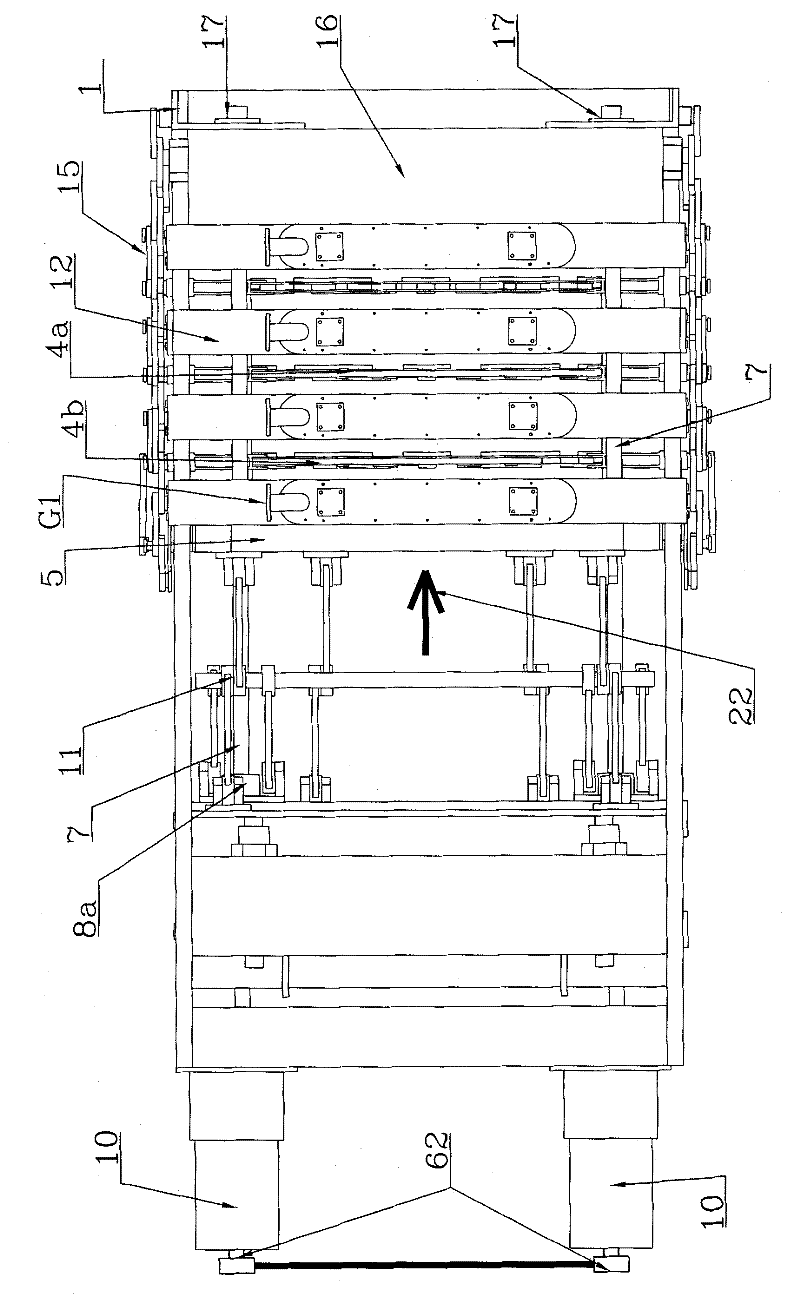

[0059] existfigure 1 , 2 , 3, 5, 6, 7, 8, 9, 10, 12, 13 and 14, a general example 1 of a flexible tube press provided with a filter element of multilayer water permeable plates is shown.

[0060] exist figure 1 It shows the appearance of a flexible pipe press machine that has been disclosed in some technologies. A frame 1 is erected on the foundation, and four filter elements 12 are arranged in parallel on the upper frame guide rails 2a of the two I-shaped steels on the frame. And can only utilize the upper and lower limit guide wheels 14 fixed on the left and right sides of the upper flange to move relatively along the front and rear directions of the arrangement, the filter tube unit 30 of the filter element 12 is clamped between the pressure plate 5 and the pressure bearing plate 16, and the front and rear directions of the arrangement are als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com