Method for preparing neutral oat concentrate by activation of spores and stabilization of proteins

A neutral, oat-based technology, applied in the field of food and beverage processing, to achieve the effects of reducing production energy consumption, increasing protein content of finished products, and shortening sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for killing microorganisms in neutral oat thick slurry, comprising the steps of:

[0035] (1) The neutral oat thick slurry to be sterilized is subjected to primary homogenization, and the primary homogenization condition is: 40MPa homogenization once; then the temperature is raised to 65°C, and the temperature is kept at a constant temperature for 0.5 hours to activate the spores, and then the temperature is lowered to 25°C ℃, to obtain thick slurry after spore activation;

[0036] (2) After the activated spores obtained in step (1) are activated, the concentrated slurry is subjected to secondary homogenization treatment, and the condition of the secondary homogenization treatment is 20MPa homogenization once, then the temperature is raised to 85°C, and the temperature is kept at a constant temperature for 50 seconds. (F 0 )=5.25 ultra-high temperature instantaneous sterilization to obtain neutral oat thick slurry.

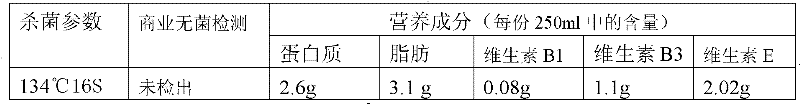

[0037] After testing, the performance of v...

Embodiment 2

[0072] (1) The neutral oat thick slurry to be sterilized is subjected to first-level homogenization, and the first-level homogenization condition is: 35MPa homogenization twice; then the temperature is raised to 70°C, and the temperature is kept at a constant temperature for 1 hour to activate the spores, and then the temperature is lowered to 25 ℃, to obtain thick slurry after spore activation;

[0073] (2) After the activated spores obtained in step (1) are activated, the concentrated slurry is subjected to secondary homogenization treatment. The condition of the secondary homogenization treatment is 30MPa homogenization once, and then the temperature is raised to 90°C, kept at a constant temperature for 30 seconds, and then subjected to sterilization intensity (F 0 )=6.61 ultra-high temperature instantaneous sterilization to obtain neutral oat thick paste.

[0074] After testing, the performance of various nutrients in the prepared oat cereal thick slurry is shown in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com