Mechanical antiskid differential

A mechanical anti-skid and differential technology, which is applied in the direction of mechanical equipment, differential transmission, belt/chain/gear, etc., can solve the problems of inability to achieve 100% anti-skid, complex structure, high material requirements, etc., and achieve broad market application prospects , fast response, lower material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

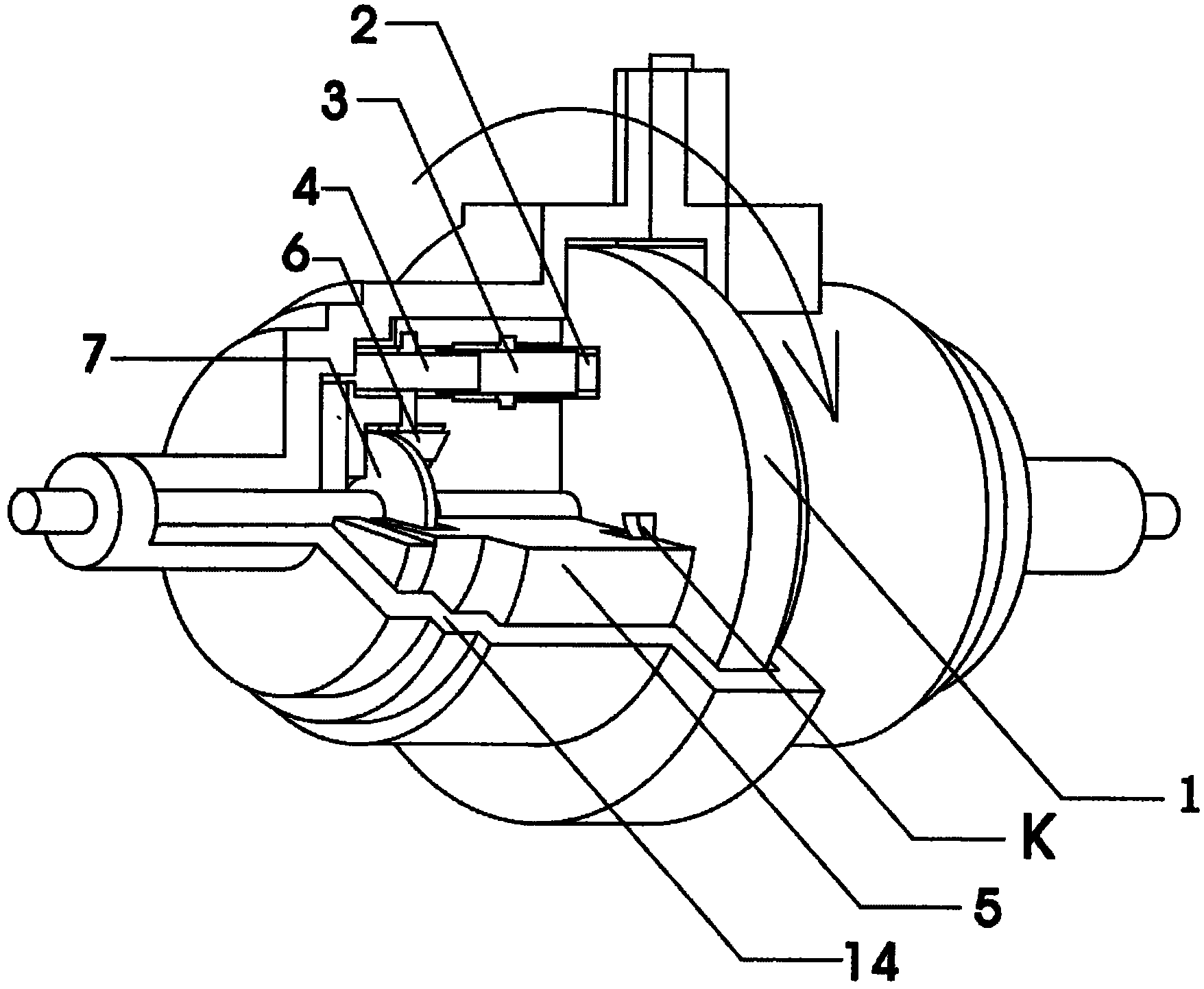

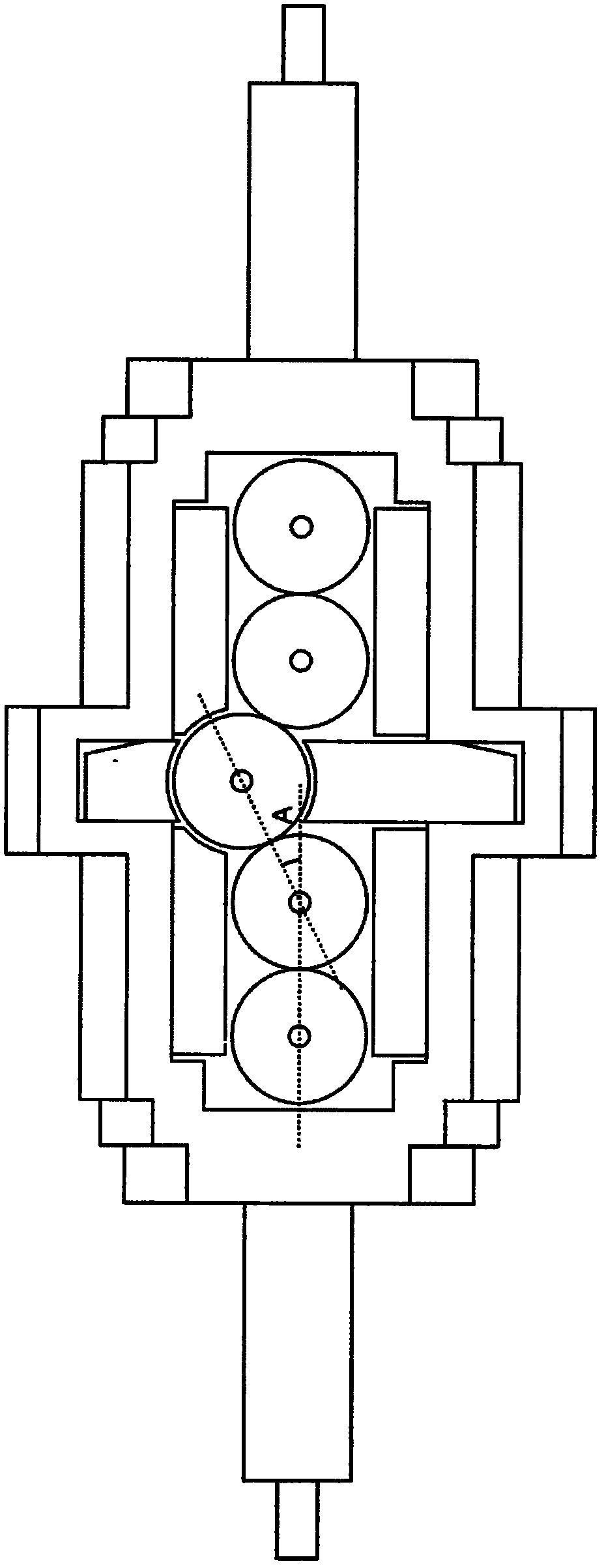

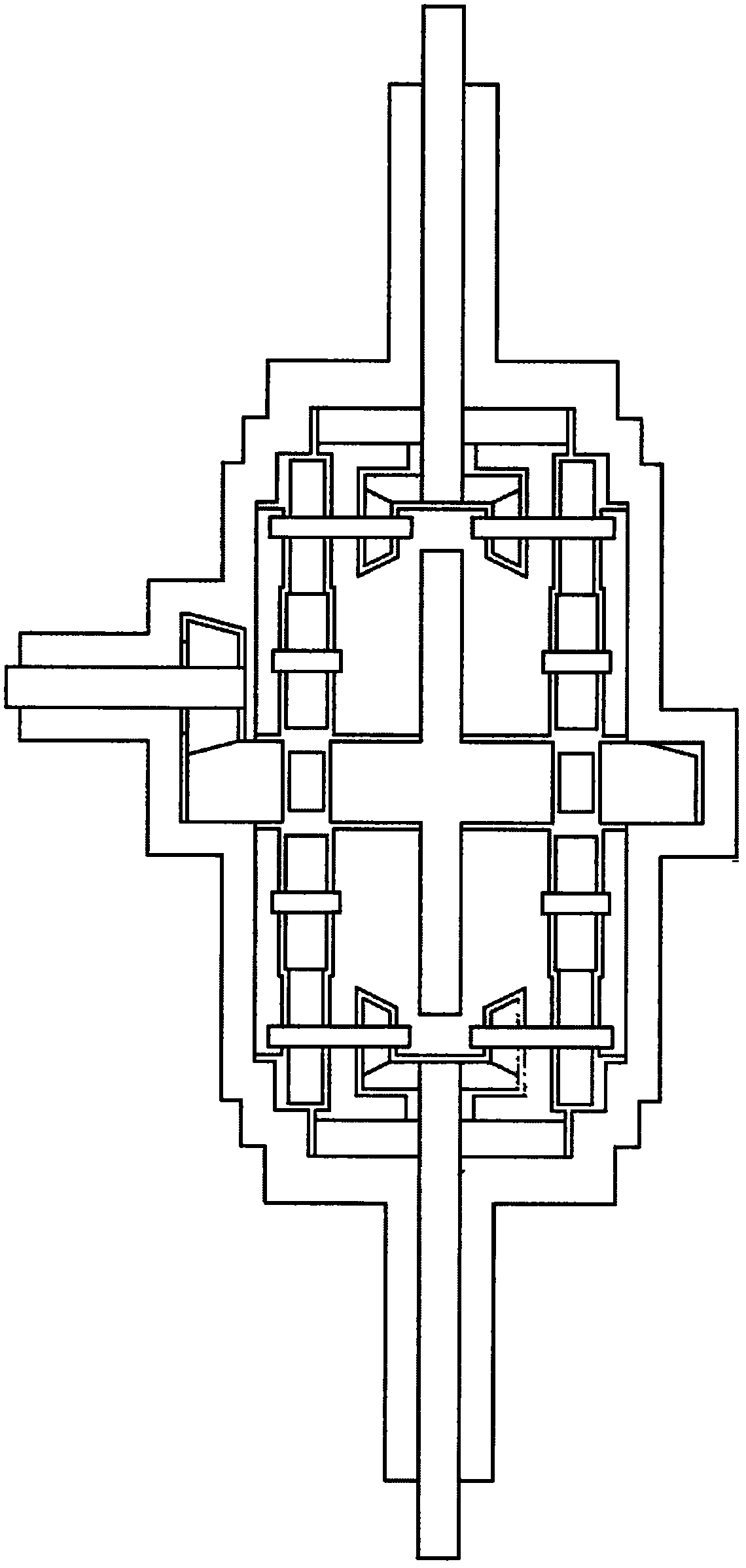

[0047] As the best embodiment of the present invention, with reference to the attached Figure 1-6 , the invention discloses a mechanical anti-slip differential, comprising a housing, a first output half shaft, a second output half shaft, a first output half shaft gear fixedly connected with the first output half shaft, and a second output half shaft The fixedly connected second output side shaft gear also includes a driving rotating member arranged in the casing, the driving rotating member is provided with a main planetary gear, and the main planetary gear is arranged through the driving rotating member; the two sides of the main planetary gear The first and second auxiliary planetary gears meshing with the main planetary gears are respectively arranged on the side, and the rims of the first auxiliary planetary gears and the second auxiliary planetary gears are on the vertical plane of the main planetary gear axis. The distance of the projection on is less than the diameter ...

Embodiment 2

[0049] Another preferred embodiment of the present invention is that the main planetary gear is arranged on the driving rotating member through through: the axial direction of the main planetary gear and the axial direction of the rotating shaft of the driving rotating member have an angle in space, and the wheel of the main planetary gear The edge protrudes from the surface of the active rotating member. There are two main planetary gears, and the sizes of the two main planetary gears are different. One of the main planetary gears meshes with the first auxiliary planetary gear, and the other main planetary gear meshes with the second auxiliary planetary gear, or there is only one main planetary gear. The revolution radii of the first auxiliary planetary gear and the second auxiliary planetary gear around the rotation axis of the driving rotating member are different. The main planetary gear, the first auxiliary planetary gear, the second auxiliary planetary gear, the first tr...

Embodiment 3

[0051] as attached Figure 5 Shown, 11 is the input shaft of differential gear, and 10 is the output shaft of differential gear. There is a bevel gear 13 at one end of the input shaft, and the bevel gear 13 is coupled with the main bevel gear 1 . The main bevel gear 1 can freely rotate along the main bevel gear shaft 12 . The main bevel gear is fixed with the main planetary gear 2 inside. The axis of the main planetary gear 2 is located in the main bevel gear 1 and is parallel to the plane of the main bevel gear 1 . The half shaft bracket 5 is fixed on the main bevel gear shaft 12 at the same time, and can rotate along the main bevel gear shaft 12 in one direction. Auxiliary planetary gears 3 and transmission planetary gears 4 are fixed on the half shaft bracket 5 . The radius of the auxiliary planetary gear 3 is r3, the radius of the transmission planetary gear 4 is r4, the transmission planetary gear 4, the auxiliary planetary gear 3 and the main planetary gear 2 are cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com