Method for preparing dyed wood pulp paper for nonwoven materials

A technology of non-woven materials and wood pulp paper, which is applied in the direction of textiles and paper making, paper making, paper machines, etc., can solve the problems of poor color fastness and color difference of wood pulp paper, and solve the problems of poor color fastness and color difference, water Improvement of immersion fastness and improvement of color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

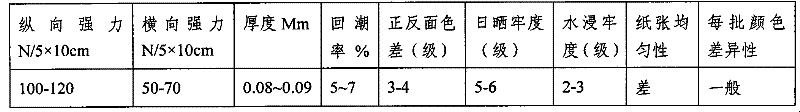

Embodiment 1

[0032] (1) get the red pine fluff pulp that the fiber length of 60% is greater than 2mm and mix with 40% coniferous wood pulp to obtain mixed wood pulp;

[0033] (2) loose pulp: put the mixed wood pulp obtained in step (1) into a loose pulp tank and add water for beating, the mass ratio of mixed wood pulp and water is 1: 120, so that the wood pulp fibers are evenly dispersed in water;

[0034] (3) Heating: heat the water in the slurry tank and keep it at 45-50°C;

[0035] (4) Dyeing: Add direct blue 2RL (direct blue 80) dyeing in the pulp tank, the add-on is 1.0% of the mixed wood pulp quality that step (1) obtains, after 20 minutes, add the formaldehyde-free fixing agent TF- 232, the addition is 2.0% of the mixed wood pulp quality that step (1) obtains, keeps 30 minutes;

[0036] (5), according to the papermaking process: stock tank→high fluid tank→laying net→suction→drying→rolling→slitting, input the dyeing slurry obtained in step (4) into the wire part of the paper machine...

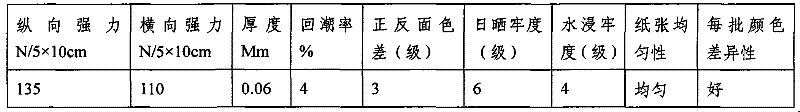

Embodiment 2

[0040] (1) mixed pulp: get the red pine fluff pulp that the fiber length of 50% is greater than 2mm and mix with 50% coniferous wood pulp to obtain mixed wood pulp;

[0041] (2) loose pulp: put the mixed wood pulp obtained in step (1) into a loose pulp tank and add water for beating, the mass ratio of mixed wood pulp and water is 1: 150, so that the wood pulp fibers are evenly dispersed in water;

[0042] (3) Heating: heat the water in the slurry tank and keep it at 45-50°C;

[0043] (4) Dyeing: add direct blue 2RL (direct blue 80)+direct yellow RL (direct yellow 86) dyeing in bulk slurry tank, add-on is respectively 1.0% and 0.2% of the mixed wood pulp quality that step (1) obtains , after 20 minutes, add formaldehyde-free color-fixing agent TF-232, the addition is 2.0% of the mixed wood pulp quality that step (1) obtains, keep 20 minutes;

[0044] (5), according to the papermaking process: stock tank→high fluid tank→laying net→suction→drying→rolling→slitting, input the dyei...

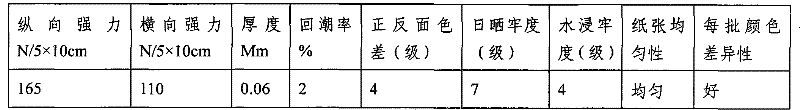

Embodiment 3

[0048] (1) mixed pulp: getting mass percent is that 70% fiber length is greater than the red pine fluff pulp of 2mm and 30% coniferous wood pulp and mixes to get mixed wood pulp;

[0049] (2) loose pulp: put the mixed wood pulp obtained in step (1) into a loose pulp tank and add water for beating, the mass ratio of mixed wood pulp and water is 1: 160, so that the wood pulp fibers are evenly dispersed in water;

[0050] (3) Heating: heat the water in the slurry tank and keep it at 45-50°C;

[0051] (4) Dyeing: Add direct sunfast turquoise blue GL (direct blue 86) dyeing in the pulp tank, the addition is 0.5% of the mixed wood pulp quality that step (1) obtains, after 20 minutes, add formaldehyde-free solid color Agent TF-232, the addition is 2.0% of the mixed wood pulp quality that step (1) obtains, keeps 20 minutes;

[0052] (5), according to the papermaking process: stock tank→high fluid tank→laying net→suction→drying→rolling→slitting, input the dyeing slurry obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com