Coal ball extrusion apparatus

An extrusion device and briquette technology, which is applied in the petroleum industry, presses, solid fuels, etc., can solve the problems of high density extrusion, easy loosening, poor use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

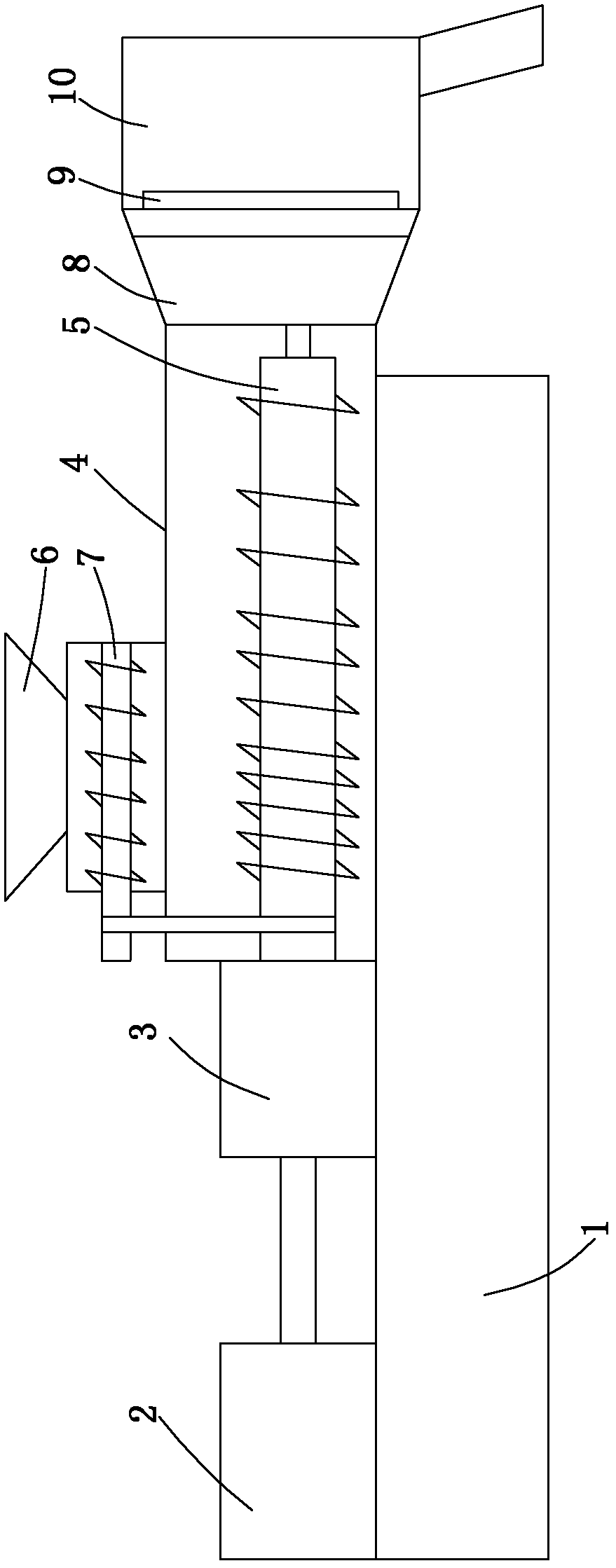

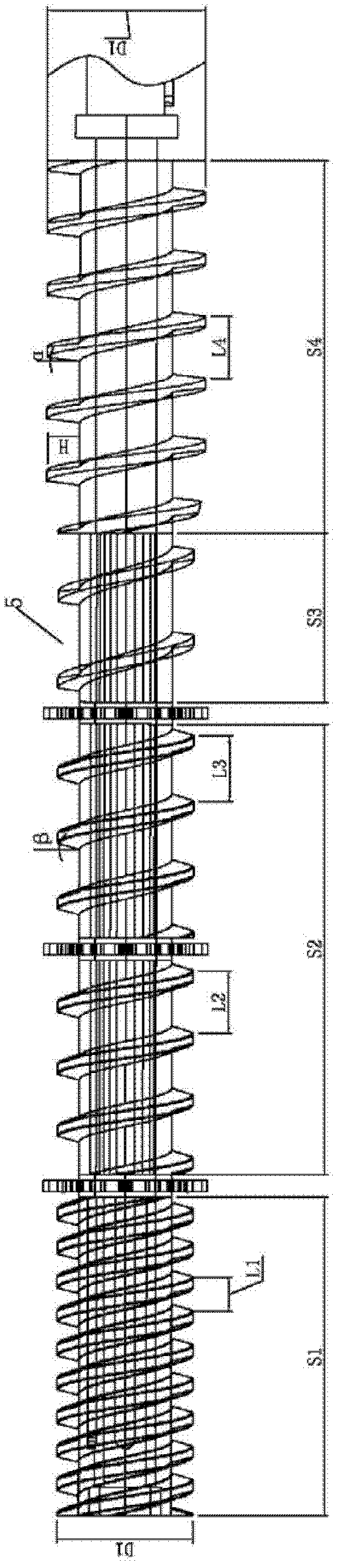

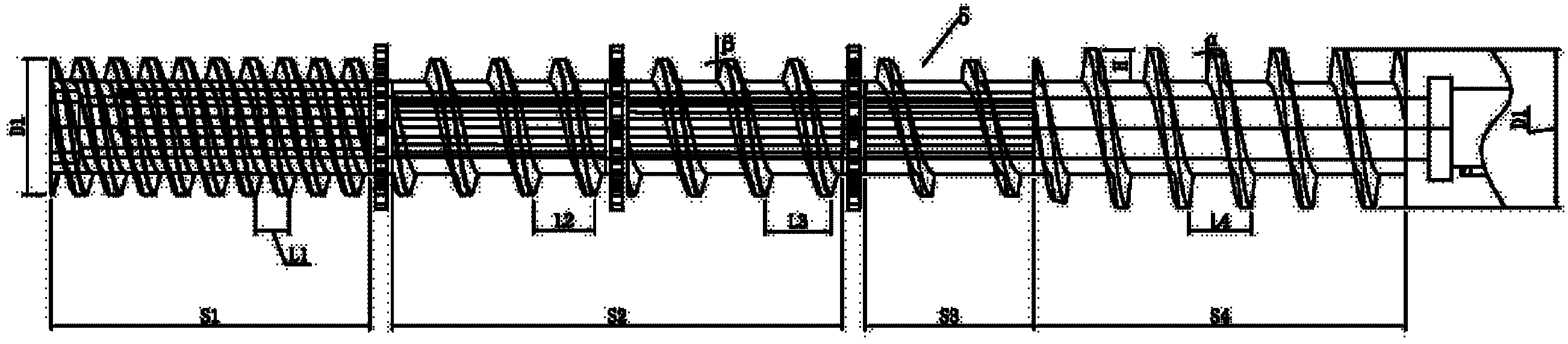

[0010] refer to figure 1 , the briquette extrusion device of the present invention, workbench 1 is provided with motor 2, and the output end of motor 2 is connected speed reducer 3, and the output end of speed reducer 3 is connected propulsion shaft 5 ( figure 1 The structure of the propulsion shaft is only schematically shown in the figure), and the propulsion shaft is provided with a feeding pre-compression section S4, a pressurization section S3, an extrusion melting section S2 and a homogenization section S1 composed of helical blades. The outer diameter D1 of the helical vane in the section S4 is larger than the outer diameter D2 of the helical vanes in the pressurizing section, extrusion-melting section and homogenizing section. The two ends of the propulsion shaft are assembled in the twisted cage 4, and the front upper end of the twisted cage 4 communicates with the coal inlet 6. The coal inlet 6 is provided with a twisted gear shaft 7, and the twisted gear shaft 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com