Vehicle mechanical energy-saving hydraulic system with multi-pump confluence

A hydraulic system and vehicle technology, applied to mechanical equipment, vehicle parts, fluid steering mechanisms, etc., can solve problems such as reducing labor productivity, wasting throttling losses, reducing engine drive power output, etc., to improve operational stability and reduce energy consumption. Effect of reducing flow loss and overflow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

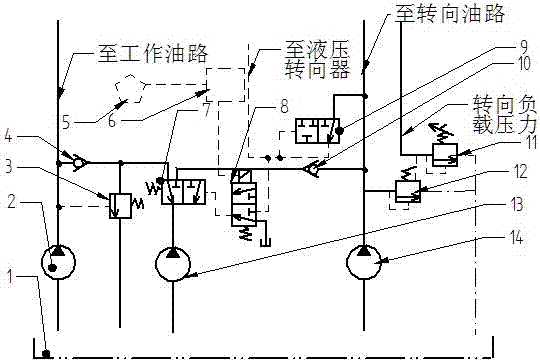

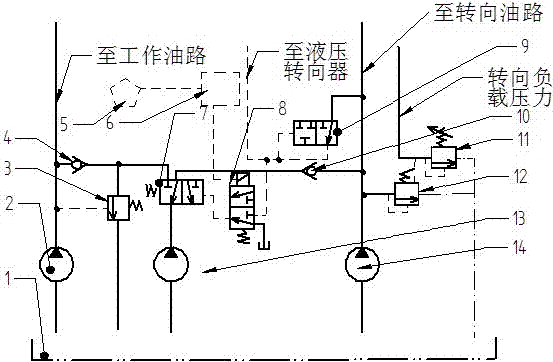

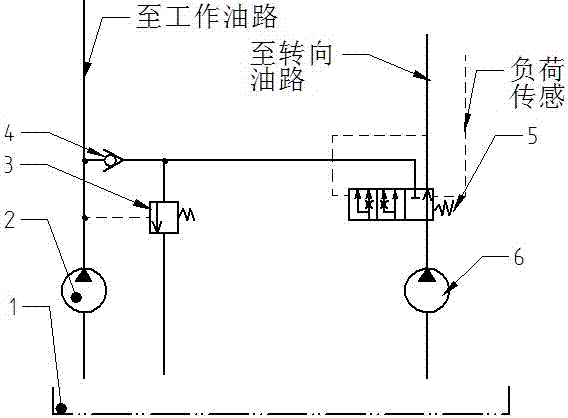

[0020] Option One( figure 1 ): When the engine speed is low, in order to ensure the required oil for the steering hydraulic system, the solenoid valve (8) is energized and opened, and part of the oil output by the pressure reducing valve (9) flows to the hydraulic steering gear, and the other part flows to the flow conversion valve The pressure control oil port overcomes the spring force of the flow switching valve (7), and when the outlet pressure of the pressure reducing valve (9) reaches a certain value, the flow switching valve (7) is in the right position, and the auxiliary pump (13) and the steering The oil output from the pump (14) merges together to supply oil to the steering hydraulic system, giving priority to steering.

[0021] When the engine speed is high, the output oil of the steering pump (14) alone has met the requirements of the steering hydraulic system; at this time, the solenoid valve (8) is powered off and closed, the flow conversion valve (7) is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com