Vibrator for feeding punching machine

A vibrator and punching technology, which is applied in the field of punching and feeding devices, can solve the problems of increasing processing capacity, power consumption, waste of power cost, and inability to perform at the same time, and achieves the effects of increasing processing capacity, saving power, and maintaining stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

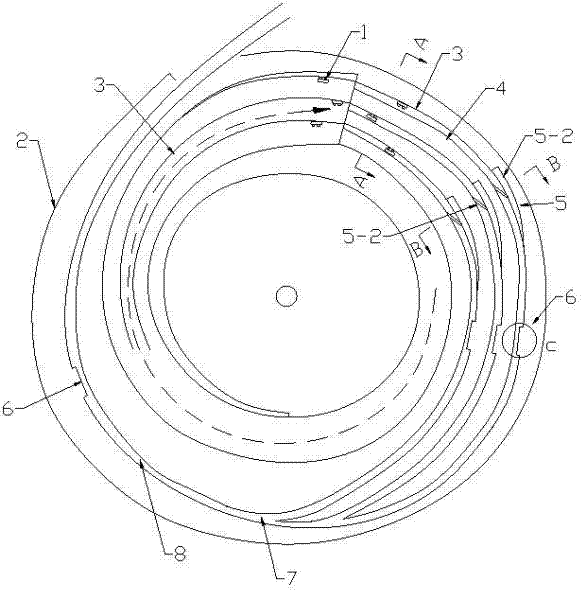

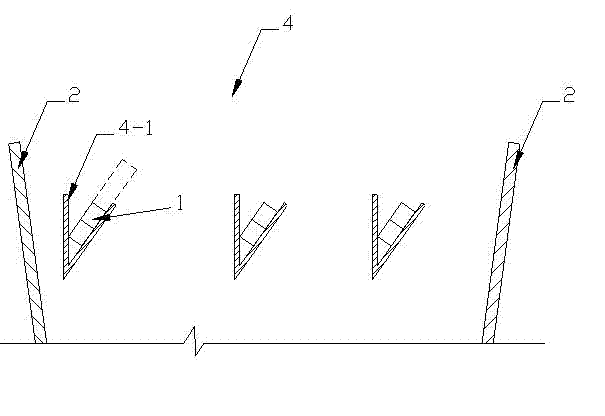

[0021] Such as figure 1 , figure 2 As shown, the workpiece 1 to be punched is thrown into the vibrator collecting hopper 2 in disorder, and the workpiece 1 moves in the same direction from the disordered state under the force of the vibration force. At the entrance of the feeding track 3, the track is increased from one to three, three The two feeding rails 3 can simultaneously adjust the direction and arrange the workpieces 1 in the same direction, so as to increase the feeding amount.

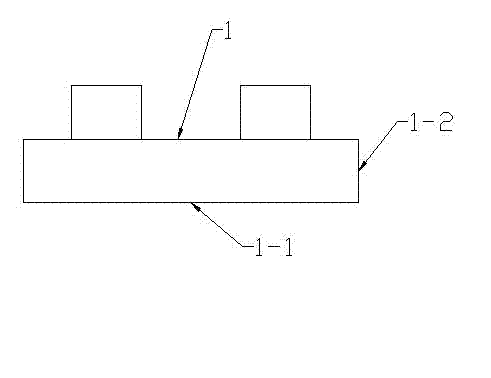

[0022] First, the workpiece 1 vibrates forward and moves through the angle adjustment section 4 along any feeding track. Workpieces such as figure 2 It is shown as a long strip, and the direction of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com