Numerically controlled shearing machine with adjustable shearing angle

A shearing angle and shearing machine technology, applied to shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve problems affecting production efficiency, troublesome operation, and non-adjustable shearing angles, etc., to achieve Easy to operate, accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

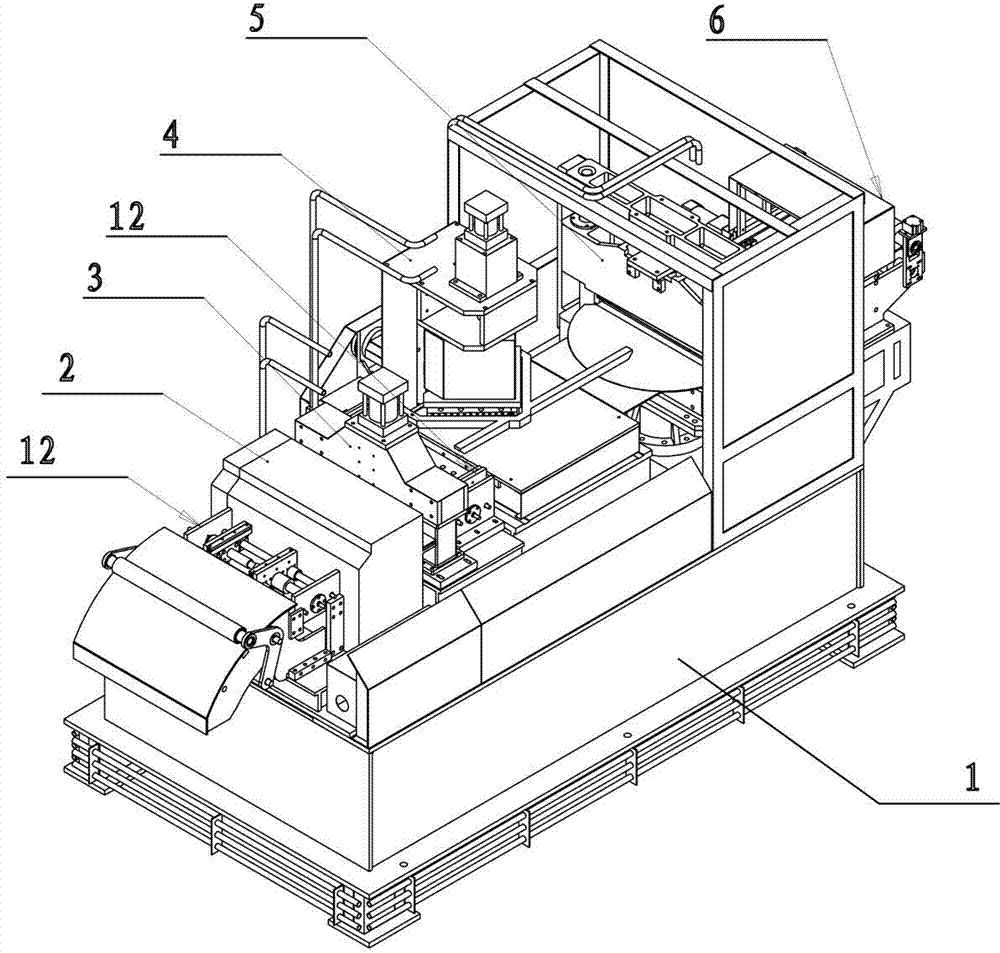

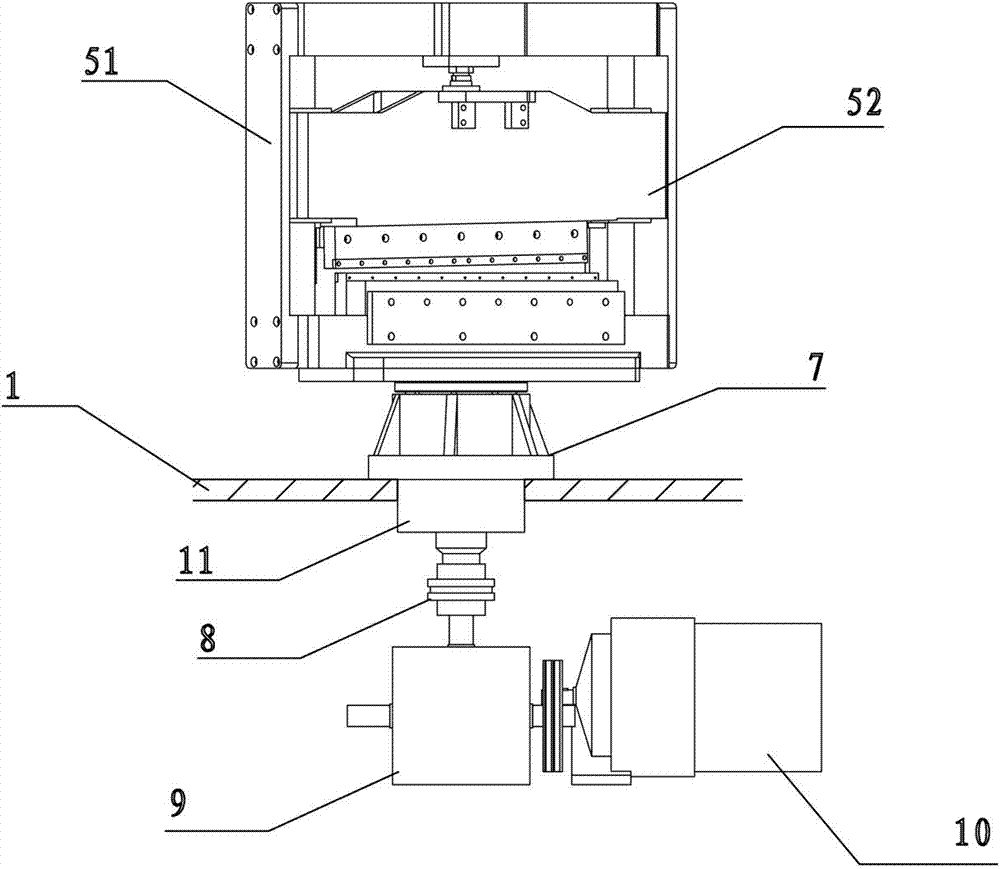

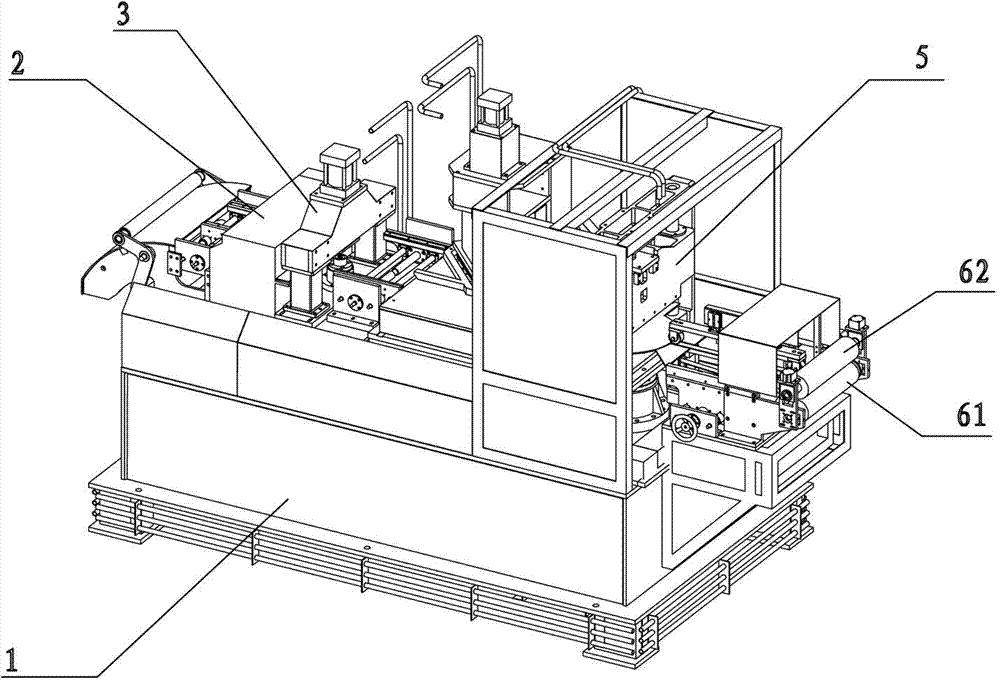

[0011] refer to Figure 1 to Figure 3 , a CNC shearing machine with adjustable shearing angle, comprising a body 1, a feeder 2 and a shearing mechanism 5 are installed on the body 1, the feeder 2 is preferably driven by a servo motor, and a stepper motor can also be used. The motor drives; the shearing mechanism 5 includes a knife rest 51 and an upper shearing knife 52 installed on the knife rest 51, the knife rest 51 is provided with a driving device, and the driving device drives the upper shearing knife 52 to move up and down along the knife rest 51, The knife rest 51 is fixedly mounted on the rotatable rotating seat 7, the upper shearing knife 52 is provided with a lower shearing knife corresponding to the rotating seat 7, and a load-bearing bearing seat mechanism 11 is arranged below the rotating seat 7, and the load-bearing bearing seat mechanism 11 Fixed on the fuselage 1, the swivel seat 7 is installed on the load-bearing bearing mechanism 11 and can rotate around its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com