Automatic conveying device for sheets

An automatic conveying device and board technology, which is applied in the directions of transportation and packaging, thin material handling, object separation, etc., can solve the problems of increasing the labor intensity of operators, reducing work efficiency, and poor safety, and achieves simple programming and use methods. Compact, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

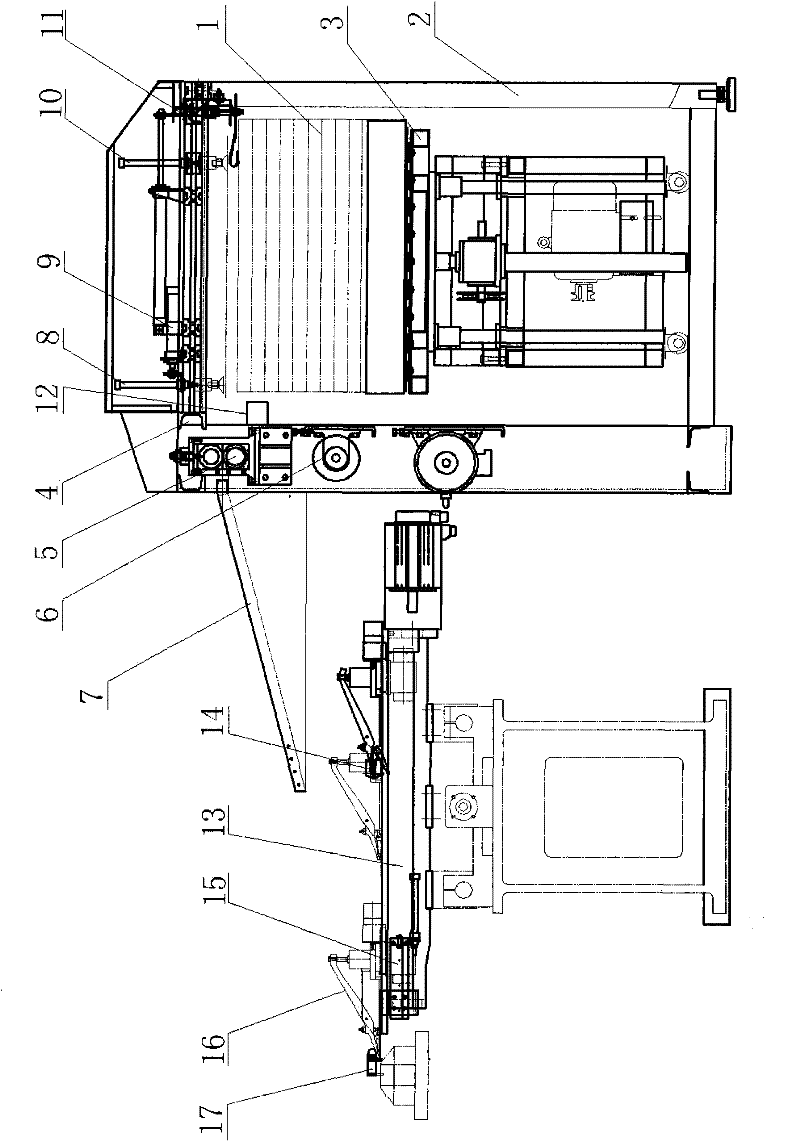

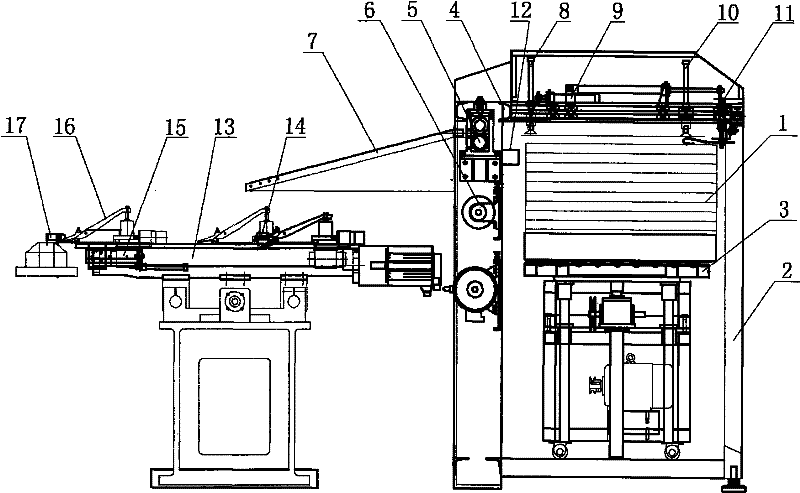

[0020] like figure 1 As shown, an automatic conveying device for board materials includes a fixed frame 2, a conveying mechanism, a positioning and processing platform 13 and an automatic lifting and positioning table 3, and the conveying mechanism is arranged above the automatic lifting and positioning table 3 through the fixed frame 2, The positioning and processing platform 13 is located on the front side of the conveying mechanism; the conveying device includes a longitudinally and laterally movable guide rail 4, a front cylinder suction cup 8, a middle cylinder support plate 9, a rear cylinder suction cup 10, and a front push cylinder push plate 11. Driven by The feeding roller 5 driven by the motor 6, the sheet material slideway bracket 7, the front cylinder suction cup 8, the middle cylinder support plate 9, the rear cylinder suction cup 10 and the forward push cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com