Nuclear radiation shielding lead clothes and production method thereof

A production method and lead coat technology, applied in the field of nuclear radiation protection, can solve the problems of large usage, falling and hurting equipment, and many wastes, etc., and achieve the effects of easy production, simple process, and reduction of lead raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Production of lead core:

[0017] First make a wooden mold of the lead clothing core, evenly lay lead fiber filaments with a diameter of 0.1mm to 0.3mm in the mold, press the wooden mold above the mold to form a lead fiber filament sheet.

[0018] Take out the shaped lead fiber flakes and spray them with natural rubber slurry.

[0019] Put the sprayed lead fiber flakes in a metal mold, place them in a high-temperature vulcanizer at 160-200°C, under a vulcanization pressure of 300kg, act for 350-450 seconds, and then cool to room temperature.

[0020] Remove the vulcanized chips from the clamping mold.

[0021] 2. Garment production:

[0022] The chips are sewn into the woven fabric to make lead clothing.

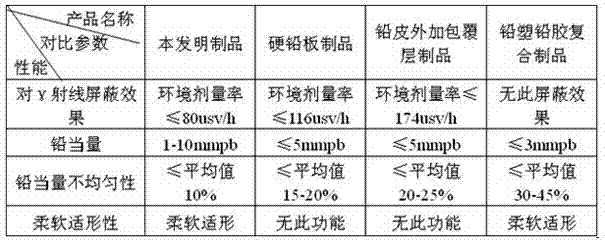

[0023] 3. Effect comparison table:

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com