Method for measuring surface harshness of multi-measuring-point floating positioning

A floating positioning and measuring method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficult to meet the measurement accuracy requirements of surface smoothness, difficult to reduce the shape and position error of support points, small surface damage, etc., to achieve convenient measurement, eliminate The effect of positioning error and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

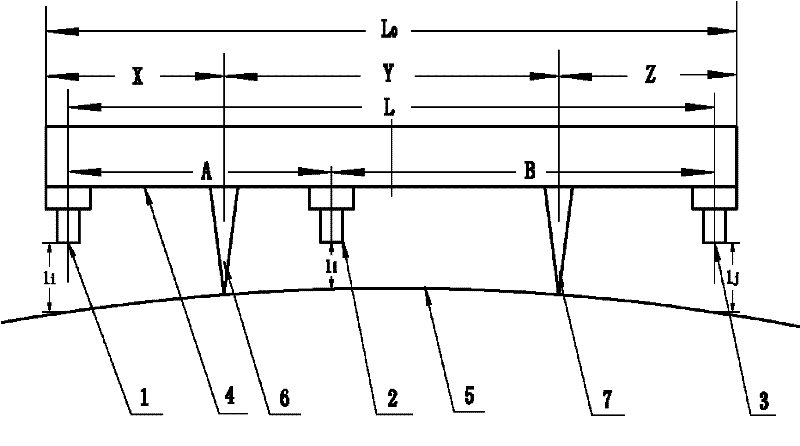

[0041] refer to figure 2 As well as the calculation formula for the surface roughness of the object, three sensors including the first sensor 1, the second sensor 2, and the third sensor 3 are used, arranged in a straight line and installed on the installation datum 4, close to the measured surface 5, and determined by a positioning device The distance between the sensor and the measured surface 5. The positioning device includes a support positioning point 6 and a support positioning point 7. The support positioning point 6 and the support positioning point 7 can satisfy the measuring range and prevent the sensor from contacting the measured surface 5. installed in any position of the installation datum 4, such as figure 2 As shown, that is, X, Y, and Z can be any value, as long as the distance between the arranged sensors and the distance from the surface to be measured can be determined; the distance L between the sensors at both ends in the first embodiment is 2m;

[00...

Embodiment 2

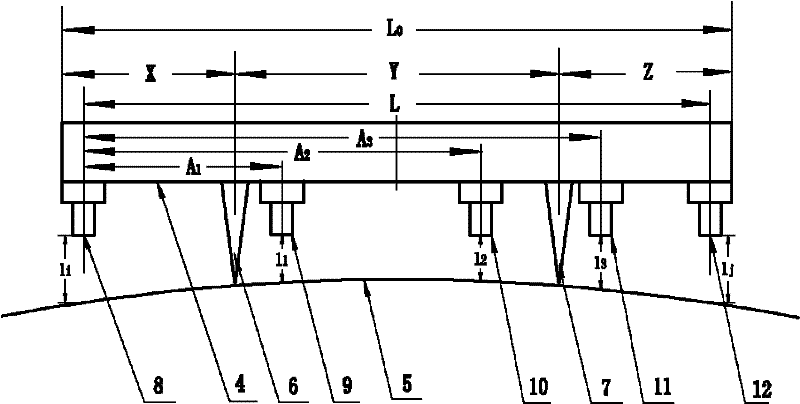

[0051] refer to image 3 And the calculation formula of the roughness of the surface of the object, adopting 5 sensors including the first sensor 8, the second sensor 9, the third sensor 10, the fourth sensor 11, and the fifth sensor 12, arranged in a straight line and installed on the installation datum 4, Close to the measured surface 5, a positioning device is used to determine the distance between the sensor and the measured surface 5. The positioning device includes a supporting positioning point 6 and a supporting positioning point 7. The supporting positioning point 6 and the supporting positioning point 7 can meet the range and Install the sensor at any position of the installation datum 4 under the premise of preventing the sensor from contacting the measured surface 5, such as image 3 As shown, that is, X, Y, and Z can be any value, as long as the distance between the arranged sensors and the distance from the surface to be measured can be determined; in the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com