Manufacturing method of fireproof conveying pipe

A production method and technology of conveying pipes, which are applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., and can solve problems such as the transportation of substances that cannot be directly applied, and open flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

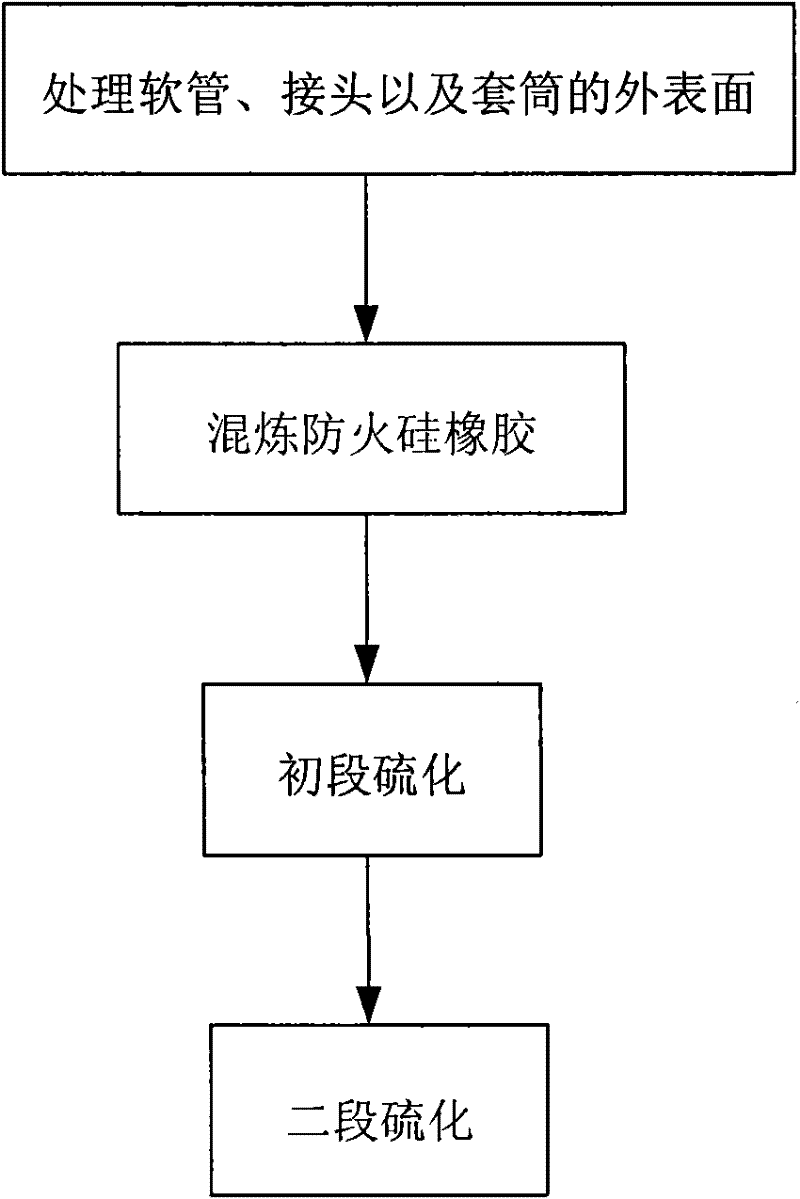

[0018] The following will combine Figure 2 ~ Figure 4 The manufacturing method of the fireproof conveying pipe of the present invention is further described in detail.

[0019] see Figure 2 ~ Figure 4 , the manufacture method of the fireproof conveying pipe of the present invention comprises the following steps:

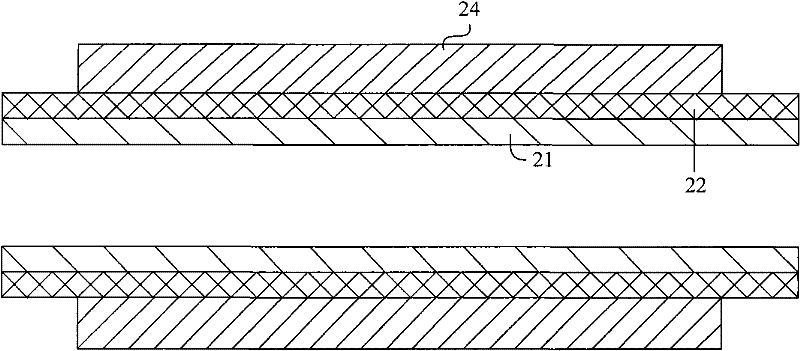

[0020] Step 1, processing the outer surfaces of the metal braided plastic hose, the joint 23 and the sleeve 25;

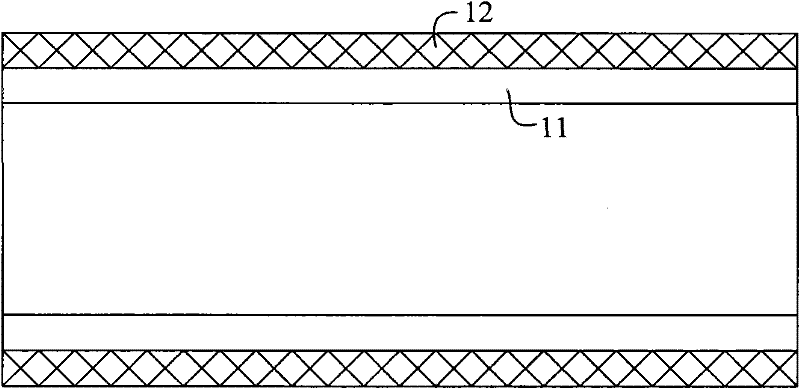

[0021] The metal braided plastic hose includes a plastic tube 21 and a metal braid 22 wrapped on the outer surface of the plastic tube 21;

[0022] The plastic tube 21 is a fluoroplastic tube made of polytetrafluoroethylene;

[0023] The metal braiding layer 22 is a steel wire braiding layer;

[0024] The outer surface of the metal braided plastic hose is the outer surface of the metal braid 22, and also the surface that needs to be bonded with fireproof materials;

[0025] The joint 23 is made of stainless steel;

[0026] The sleeve 25 is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com