Ceiling system applicable to large-span space steel structure and construction method thereof

A steel structure and space-spanning technology, applied in ceilings, building components, building structures, etc., can solve problems such as inability to connect keel structures and aluminum panel systems in series, inconvenient fabrication, installation, and maintenance, and failure to meet green construction requirements. Achieve strong promotional value and market competitiveness, durability, economy, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention provides a ceiling system and a construction method suitable for large-span space steel structures. In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

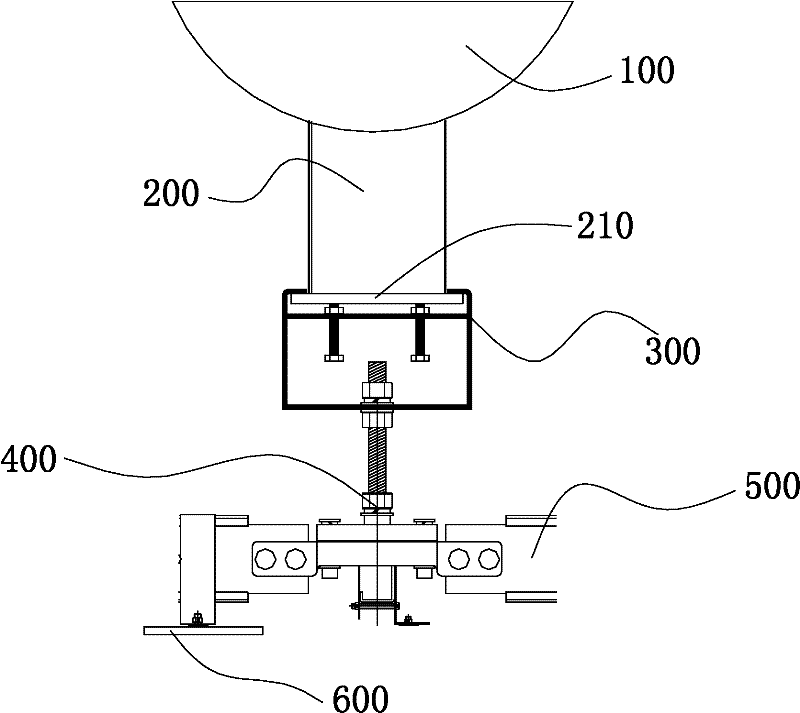

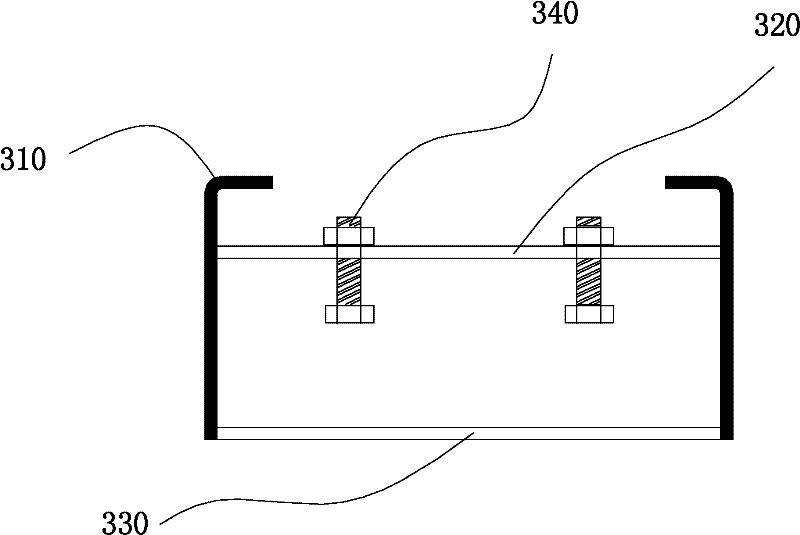

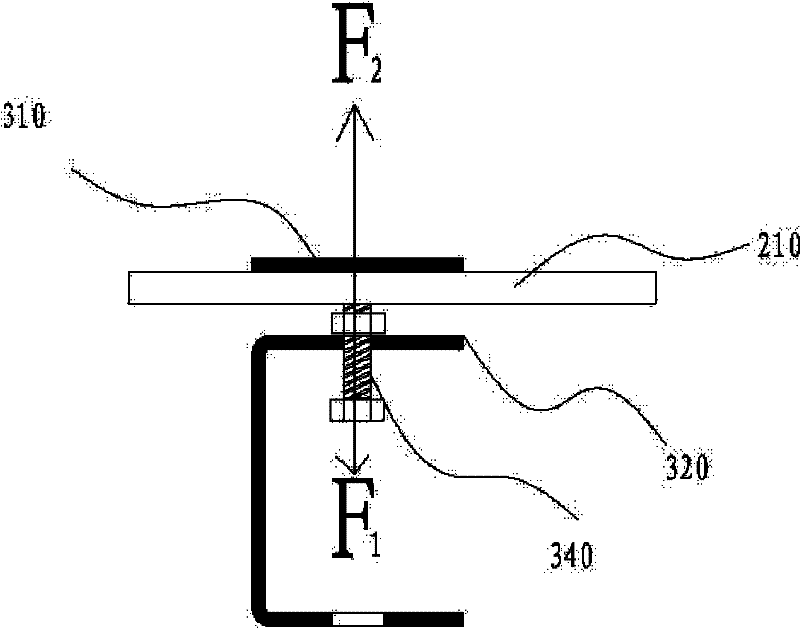

[0040] see figure 1 , figure 1 It is a schematic diagram of a ceiling system suitable for a large-span space steel structure according to an embodiment of the present invention. As shown in the figure, the ceiling system suitable for long-span steel structures includes a spherical structure 100 , steel ball columns 200 , adjustable mounting base 300 , three-dimensionally adjustable hoisting tray 400 , ceiling keel 500 and panel 600 . The sphere structure 100 and the steel ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com