Preparation and use of bacillus subtilis and clostridium butyricum composite bacterial preparation

A technology of Bacillus subtilis and Clostridium butyricum, applied in the direction of application, bacteria, and microbial-based methods, can solve the problems of reducing equipment utilization, difficulty in cultivating, and increasing energy consumption, so as to promote colonization, enhance the effect, The effect of strong competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

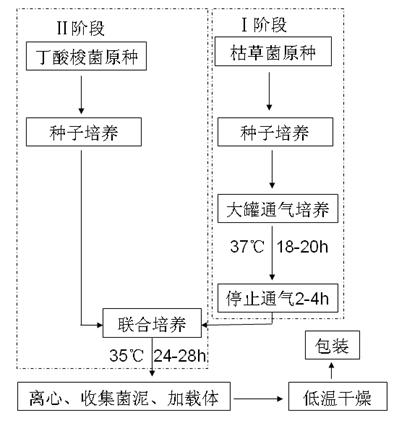

Method used

Image

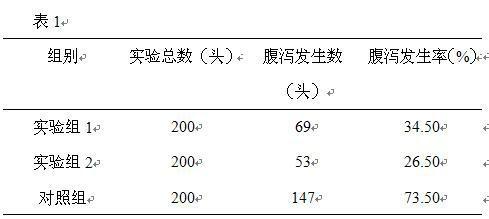

Examples

Embodiment 1

[0025] 1. Prepare the seed culture solutions of Bacillus subtilis and Clostridium butyricum respectively, in which the concentration of the bacteria solution is 5.0×10 8 CFU / ml.

[0026] 2. Make a joint medium, specifically: high-temperature bean cake powder 1.8%, urea 0.1%, corn steep liquor 0.1%, corn starch 0.5%, dipotassium hydrogen phosphate 0.1%, potassium dihydrogen phosphate 0.1%, magnesium sulfate 0.1%, sulfuric acid Manganese 0.01%.

[0027] 3. Add the Bacillus subtilis seed liquid in step 1 to the joint culture medium at a ratio of 2%, and use 10% dilute hydrochloric acid or 10% sodium hydroxide to automatically adjust the pH value to 7.0, ventilate, stir, and control dissolved oxygen 20%, cultured at 37°C for 20 hours, then stopped aeration, and continued stirring for 2 hours.

[0028] 4. Add the Clostridium butyricum seed solution in step 1 to the joint medium at a ratio of 2% using a peristaltic pump, and culture at 35°C for 28 hours. Sampling was taken to det...

Embodiment 2

[0031] 1. Prepare the seed culture solutions of Bacillus subtilis and Clostridium butyricum respectively, and the concentration of the bacteria solution is 1.0×10 8 CFU / ml.

[0032] 2. Make a joint medium, specifically: high-temperature bean cake powder 2.5%, urea 0.2%, corn steep liquor 0.3%, corn starch 0.7%, dipotassium hydrogen phosphate 0.3%, potassium dihydrogen phosphate 0.3%, magnesium sulfate 0.2%, sulfuric acid Manganese 0.02%.

[0033] 3. Add the Bacillus subtilis seed liquid in step 1 to the joint culture medium at a ratio of 2%, use 10% dilute hydrochloric acid or 10% sodium hydroxide to automatically adjust the pH value to 6.8, ventilate, stir, and control dissolved oxygen 30%, cultured at 37°C for 20 hours, then stopped aeration, and continued stirring for 2 hours.

[0034] 4. Add the Clostridium butyricum seed solution in step 1 to the joint medium at a ratio of 2% using a peristaltic pump, and culture at 35°C for 26 hours. Sampling was taken to detect the t...

Embodiment 3

[0037] 1. Prepare the seed culture solutions of Bacillus subtilis and Clostridium butyricum respectively, and the concentration of the bacteria solution is 0.5×10 8 CFU / ml.

[0038] 2. Make a joint culture medium, specifically: high-temperature bean cake powder 3.5%, urea 0.3%, corn steep liquor 0.5%, corn starch 1.0%, dipotassium hydrogen phosphate 0.5%, potassium dihydrogen phosphate 0.5%, magnesium sulfate 0.3%, sulfuric acid Manganese 0.05%.

[0039] 3. Add the Bacillus subtilis seed liquid in step 1 to the joint culture medium at a ratio of 5%, and use 10% dilute hydrochloric acid or 10% sodium hydroxide to automatically adjust the pH value to 6.5, ventilate, stir, and control dissolved oxygen 20%, cultured at 37°C for 18 hours, then stopped aeration, and continued stirring for 2 hours.

[0040] 4. Add the Clostridium butyricum seed liquid in step 1 to the joint medium at a ratio of 2% using a peristaltic pump, and culture at 35°C for 24 hours. Sampling was carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com