Rectification and crystallization method of glucurolactone

A technology of glucuronolactone and seed crystals, which is applied in the field of medicine, can solve problems such as low product content, poor product crystal form, and difference in effect, and achieve the effect of ensuring crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

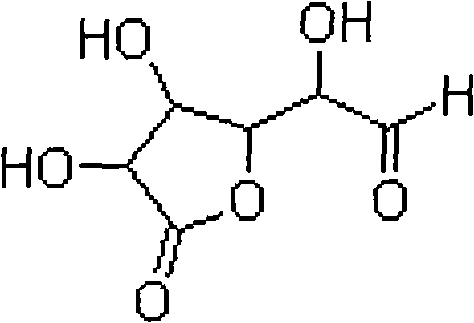

Image

Examples

Embodiment 1

[0037] Embodiment 1, refining method of the present invention

[0038] Mix 500kg of cornstarch and 550kg of 75% nitric acid in a reaction kettle, add 10kg of sodium nitrite at the same time, and then react at 45°C for 5 hours. Kettle, carry out pressure hydrolysis at 0.25~0.28Mpa, about 135°C for 1 hour, after hydrolysis is complete, the hydrolyzate is concentrated in vacuum below 55°C to a concentration of about 45Be, and the concentrate is mixed with glacial acetic acid 250kg at 45°C for esterification, and kept for 16hrs , and then concentrate the esterification solution, the concentrated esterification solution was cooled and crystallized for 3 days, and centrifuged to obtain 105 kg of crude glucuronolactone.

[0039] Add 80kg of purified water into the decolorization kettle, and add 100kg of crude glucuronolactone under stirring condition. Raise the temperature to 85°C, add 5kg of activated carbon, decolorize for 15 minutes, heat filter, transfer the filtrate to a crysta...

Embodiment 2

[0040] Embodiment 2, refining method of the present invention

[0041] Mix 500kg of cornstarch and 550kg of 78% nitric acid in a reaction kettle, add 10kg of sodium nitrite at the same time, and then react at 45°C for 5 hours. Kettle, carry out pressure hydrolysis at 0.25~0.28Mpa, 135°C for 1 hour, after hydrolysis is complete, the hydrolyzate is concentrated in vacuum at a temperature lower than 55°C to a concentration of about 45Be, and the concentrate is mixed with 250kg of glacial acetic acid at 45°C for esterification, and kept for 15hrs. Then the esterified solution was concentrated again, and the concentrated esterified solution was cooled and crystallized for 3 days, and centrifuged to obtain 108 kg of crude glucuronolactone.

[0042] Add 100kg of purified water into the decolorization kettle, and add 100kg of powdered crude glucuronolactone under stirring conditions. Raise the temperature to 75°C, add 1kg of activated carbon, decolorize for 5 minutes, heat filter, tr...

Embodiment 3

[0043] Embodiment 3, refining method of the present invention

[0044] Mix 500kg of cornstarch and 550kg of 78% nitric acid in a reaction kettle, add 10kg of sodium nitrite at the same time, and then react at 45°C for 5 hours. Kettle, carry out pressure hydrolysis at 0.25~0.28Mpa, 138°C for 1 hour, after hydrolysis is complete, the hydrolyzate is concentrated in vacuum at a temperature lower than 55°C to a concentration of about 45Be, and the concentrate is mixed with 250kg of glacial acetic acid at 45°C for esterification, and kept for 16hrs. Then the esterified solution was concentrated again, and the concentrated esterified solution cooled and crystallized for 3 days, and centrifuged to obtain 106 kg of crude glucuronolactone.

[0045] Add 80kg of purified water into the decolorization kettle, and add 100kg of crude glucuronolactone under stirring condition. Raise the temperature to 80°C, add 3kg of activated carbon, decolorize for 10 minutes, heat filter, transfer the filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com