Automatic die input and output mechanism for thermosol pipe die

A mold, automatic technology, applied in the direction of household appliances, tubular items, other household appliances, etc., can solve the problems of delaying time, affecting production efficiency, weight weight, etc., achieving a high degree of automation, compact structure, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

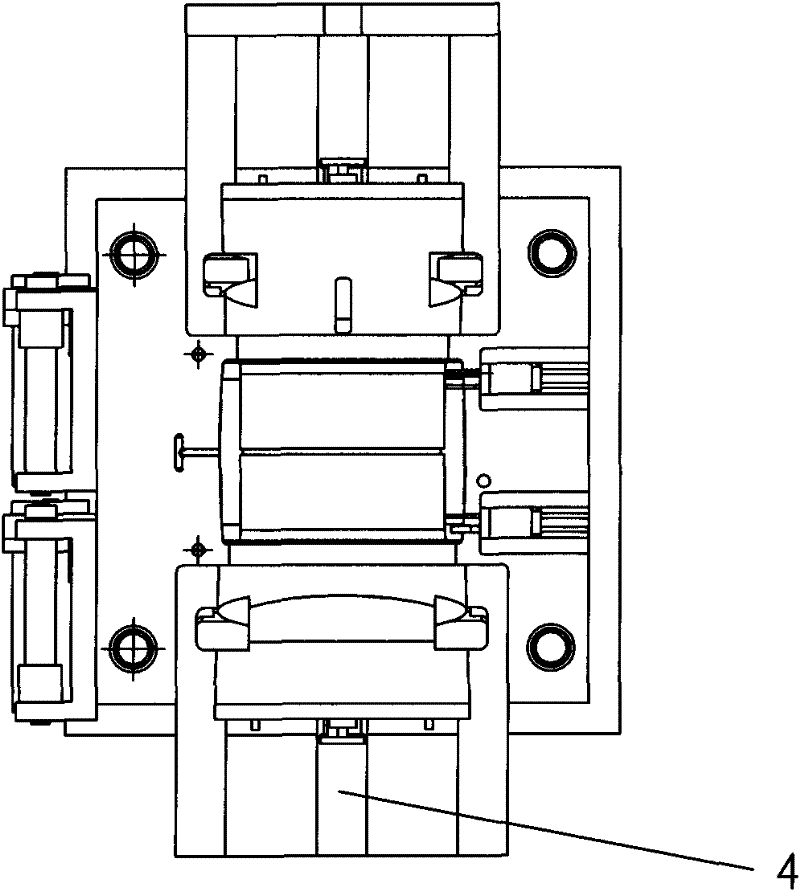

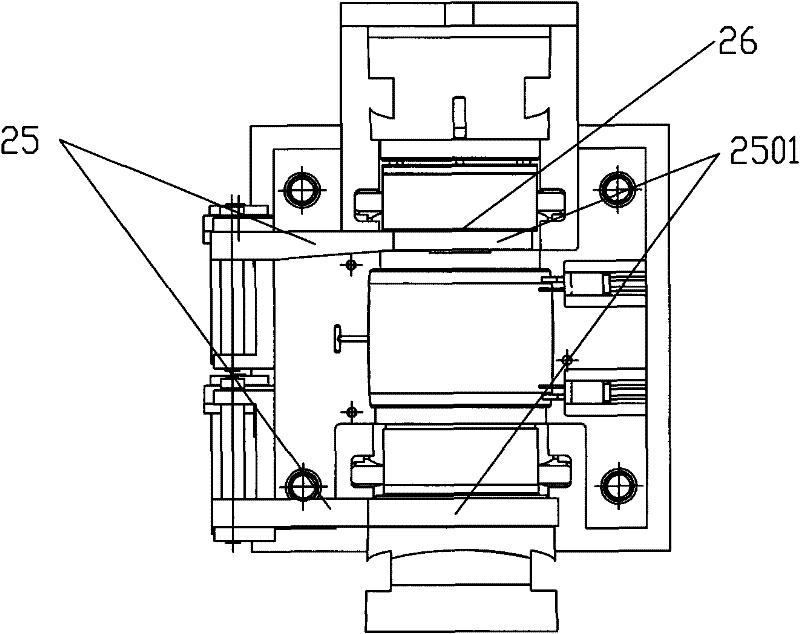

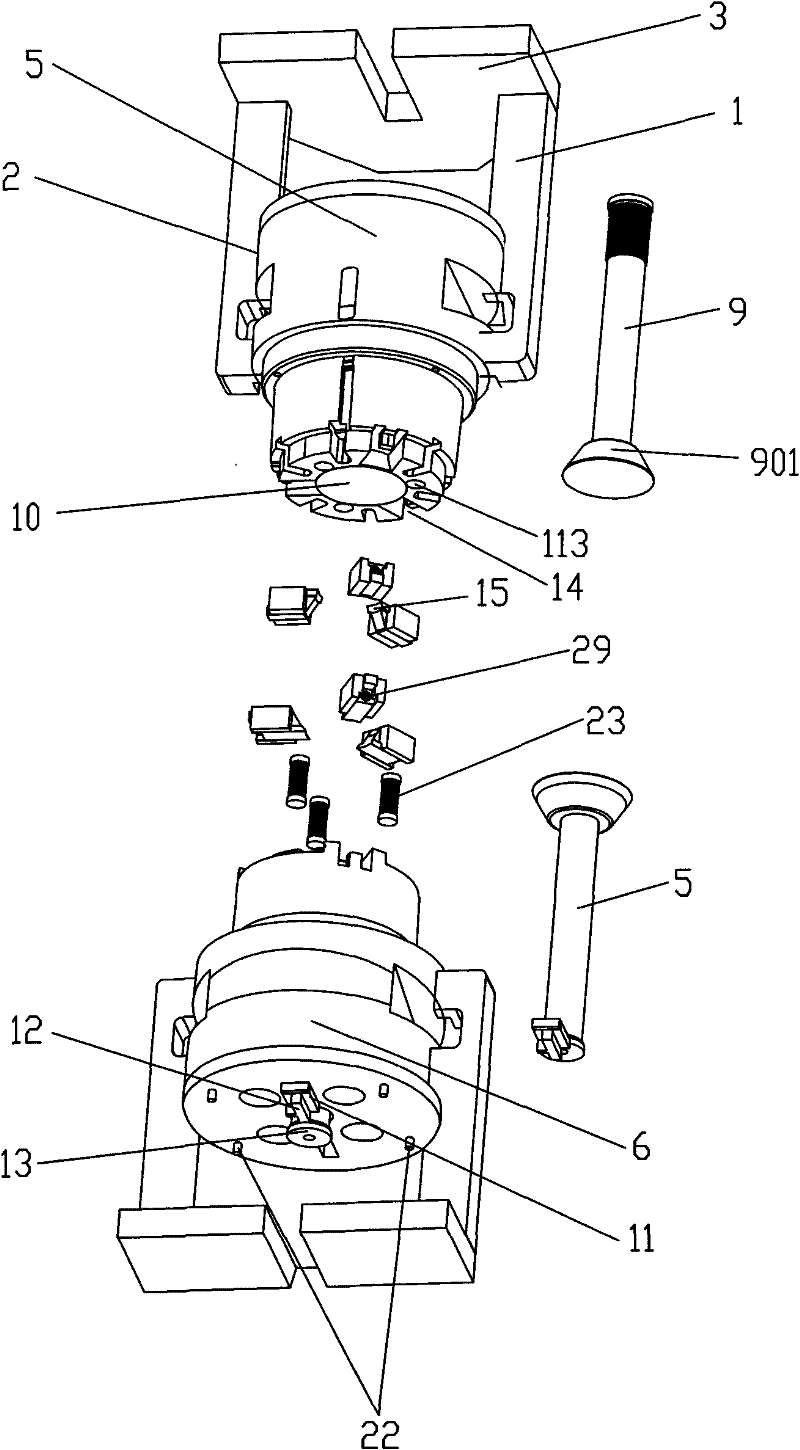

[0021] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

[0022] Provide an automatic mold entry and exit mechanism for hot-melt pipe molds, including a core formed by the cooperation of an upper core 5 and a lower core 6, and guides that cooperate with the guide rod 1 are provided on both sides of the upper core 5 and the lower core 6 Groove 2, the guide rods 1 on both sides of the upper core 5 and the lower core 6 are connected by a fixed block 3, and the tail of the upper core 5 and the lower core 6 is connected with an oil cylinder shaft 4, which is driven by the oil cylinder connected with the oil cylinder shaft 4 The upper core 5 and the lower core 6 move up and down along the guide rod 1 to realize the mold opening and closing action, the upper core 5 is accommodated in the upper cylinder liner 7, and the lower core 6 is accommodated in the lower cylinder liner 8; Both the upper core 5 and the lower core 6 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com