Grinding wheel and fixing disc thereof

A technology of grinding wheel and fixed disk, which is applied in the direction of bonded grinding wheel, abrasive material, metal processing equipment, etc., can solve the problems of grinding wheel material waste and grinding wheel material cannot be recycled, and achieve easy manufacturing and use, saving raw materials, transmission good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

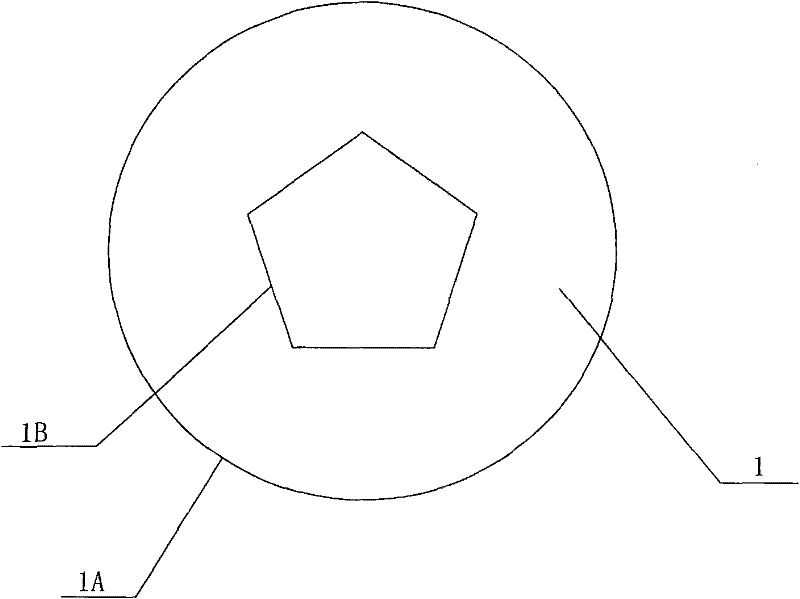

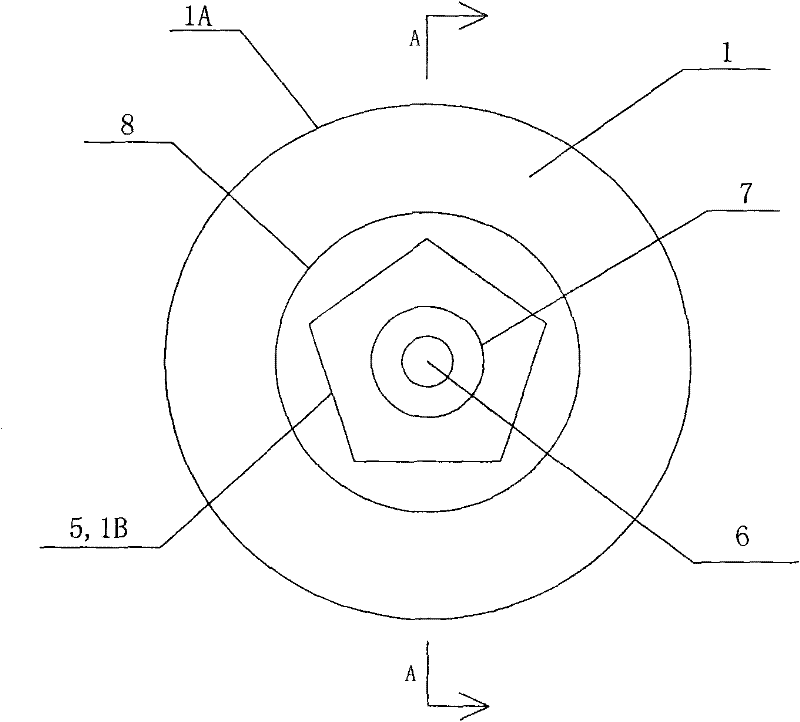

[0019] like figure 1 , image 3 and Figure 4 As shown, the grinding wheel sheet of the present invention comprises an annular substrate 1, the shape of the outer edge 1A of the annular substrate 1 is a circle and the shape of its inner edge 1B is a polygonal shape, and the shape of the inner edge 1B of the annular substrate 1 is also Can be toothed or other non-circular shapes.

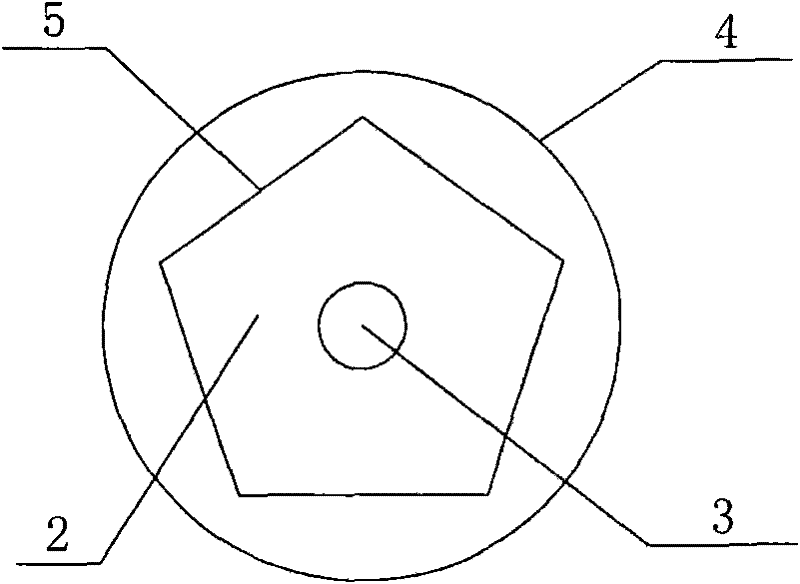

[0020] like figure 2 , image 3 and Figure 4 As shown, the fixed disk of the present invention includes a disk body 2, the center of the disk body 2 is provided with a mounting hole 3, and the radial protrusion on one side of the outer edge of the disk body 2 makes the disk body form a shoulder-shaped boss, and the shoulder-shaped boss includes a base Part 4 and the protruding part, the protruding part is the annular substrate mounting part 5 and its shape matches the shape of the inner edge 1B of the annular substrate. Wherein, the material of the disc body 2 is cast iron, and may also be al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com