Hydrolysate self-evaporator

A self-evaporator and hydrolyzate technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient repair and maintenance, inconvenient control of liquid level, high cost of repair and maintenance, and reduce maintenance Maintenance cost, easy maintenance and repair, avoiding the effect of airflow impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

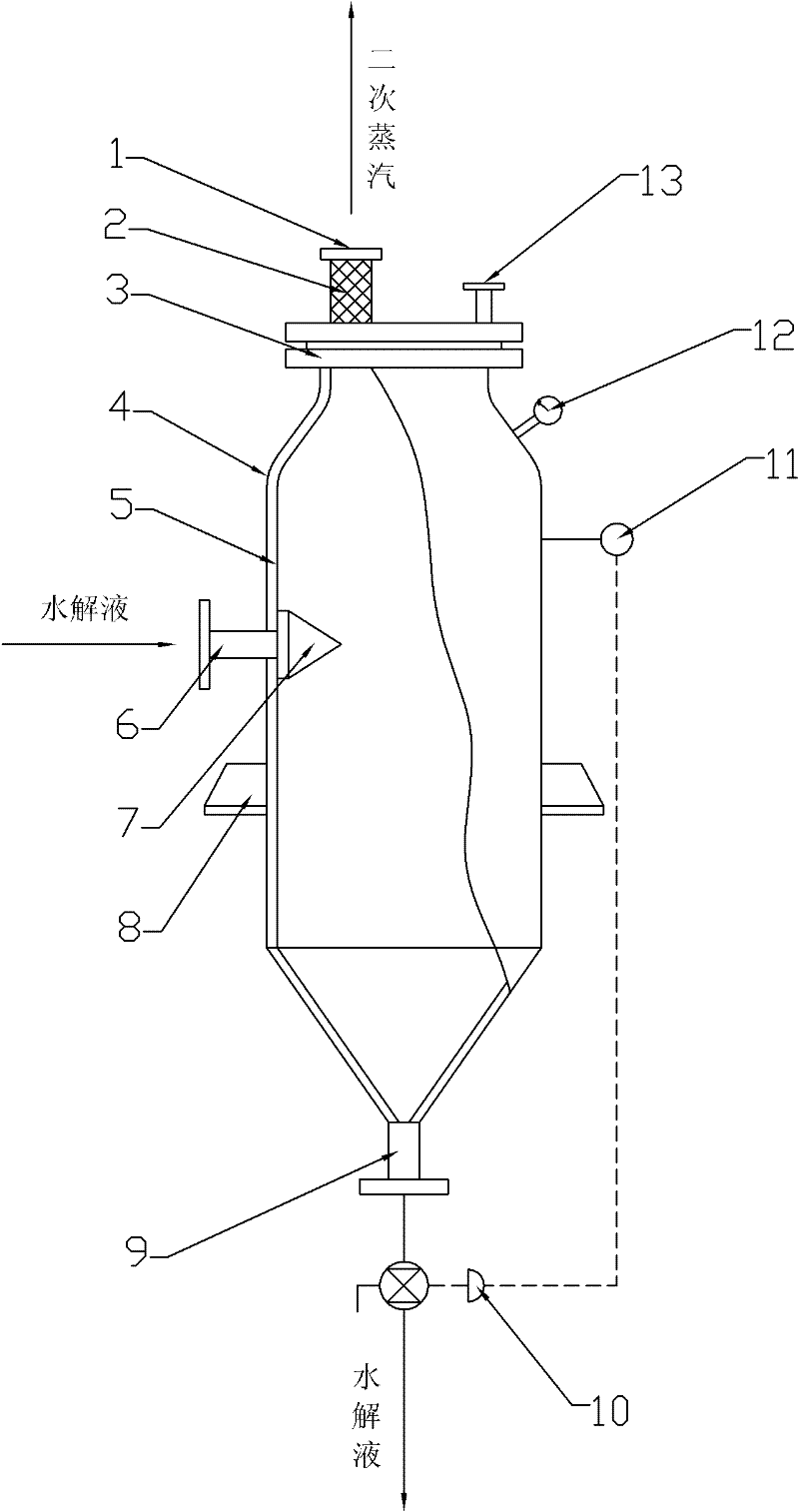

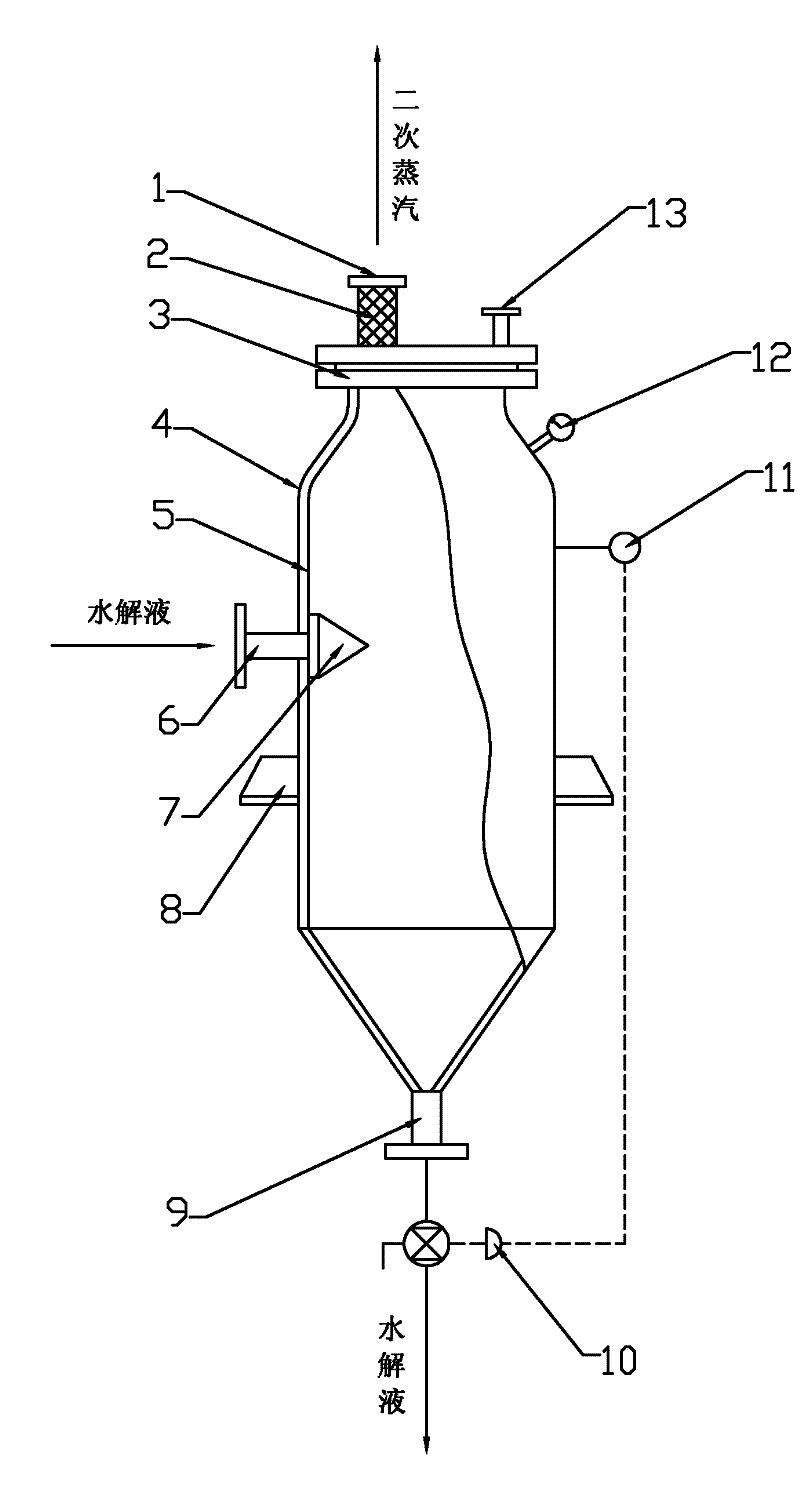

[0018] Such as figure 1 As shown, the hydrolyzed liquid self-evaporator includes a shell 4 and an inner lining 5 arranged in the shell 4. The top of the shell 4 is provided with a secondary steam outlet 1, and the bottom of the shell 4 is provided with a hydrolyzed liquid outlet 6. 4 is provided with a hydrolyzed liquid inlet 6 on the side wall, a liquid level sensor 11 is provided on the side wall of the housing 4, and an electric regulating valve 10 is provided at the hydrolyzed liquid outlet 9. The electric regulating valve 10 and the liquid level The sensor 11 is connected.

[0019] In order to facilitate maintenance and repair, a manhole flange 3 is provided on the top of the casing 4, and a gland is arranged on the upper part of the manhole flange 3, and the secondary steam outlet 1 is provided on the gland.

[0020] A reflux inlet 13 is also provided on the gland.

[0021] In order to prevent the hydrolyzed liquid from entering the casing 4 from impacting the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com