Anti-overflow food processing machine

A food processing machine and anti-spill technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as affecting the normal use of food processing machines, different installation processes of anti-spill devices, and difficulty in cleaning mixing cups. risk, increased safety and reliability, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

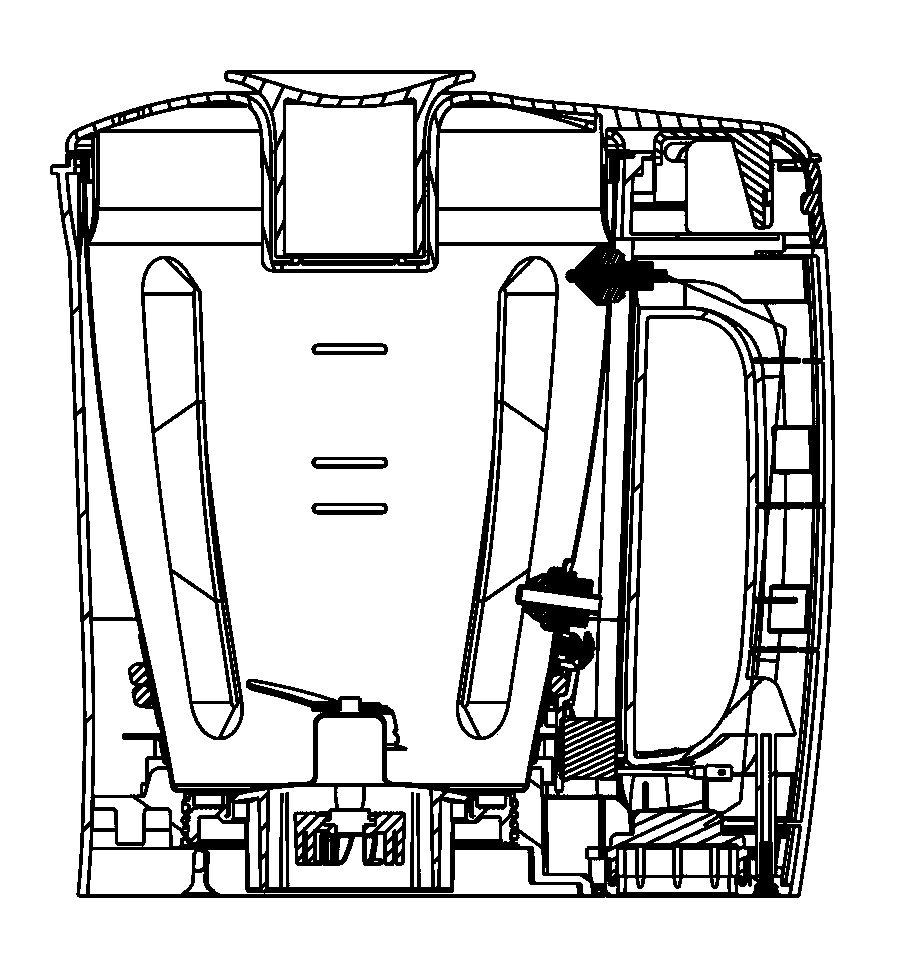

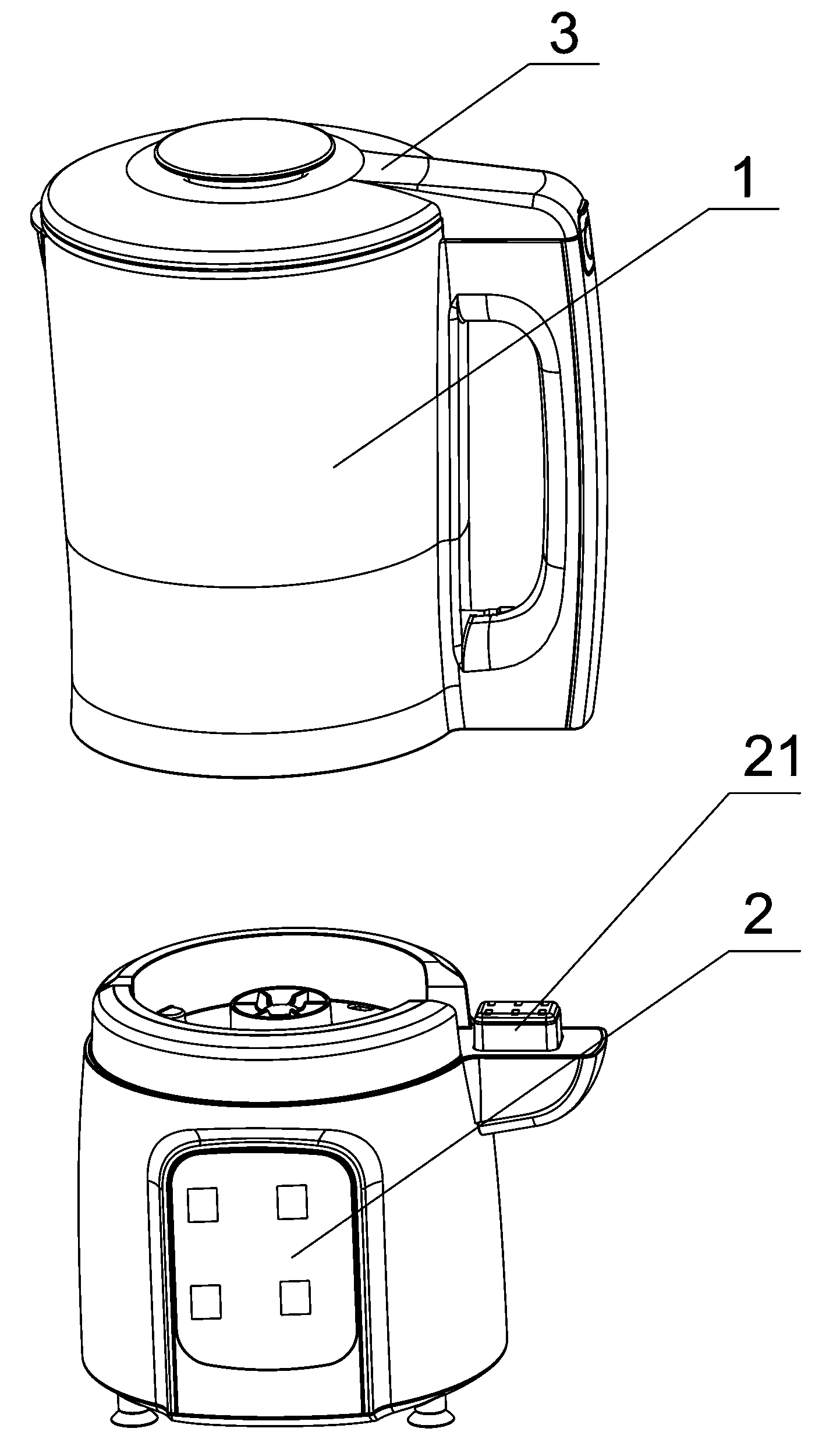

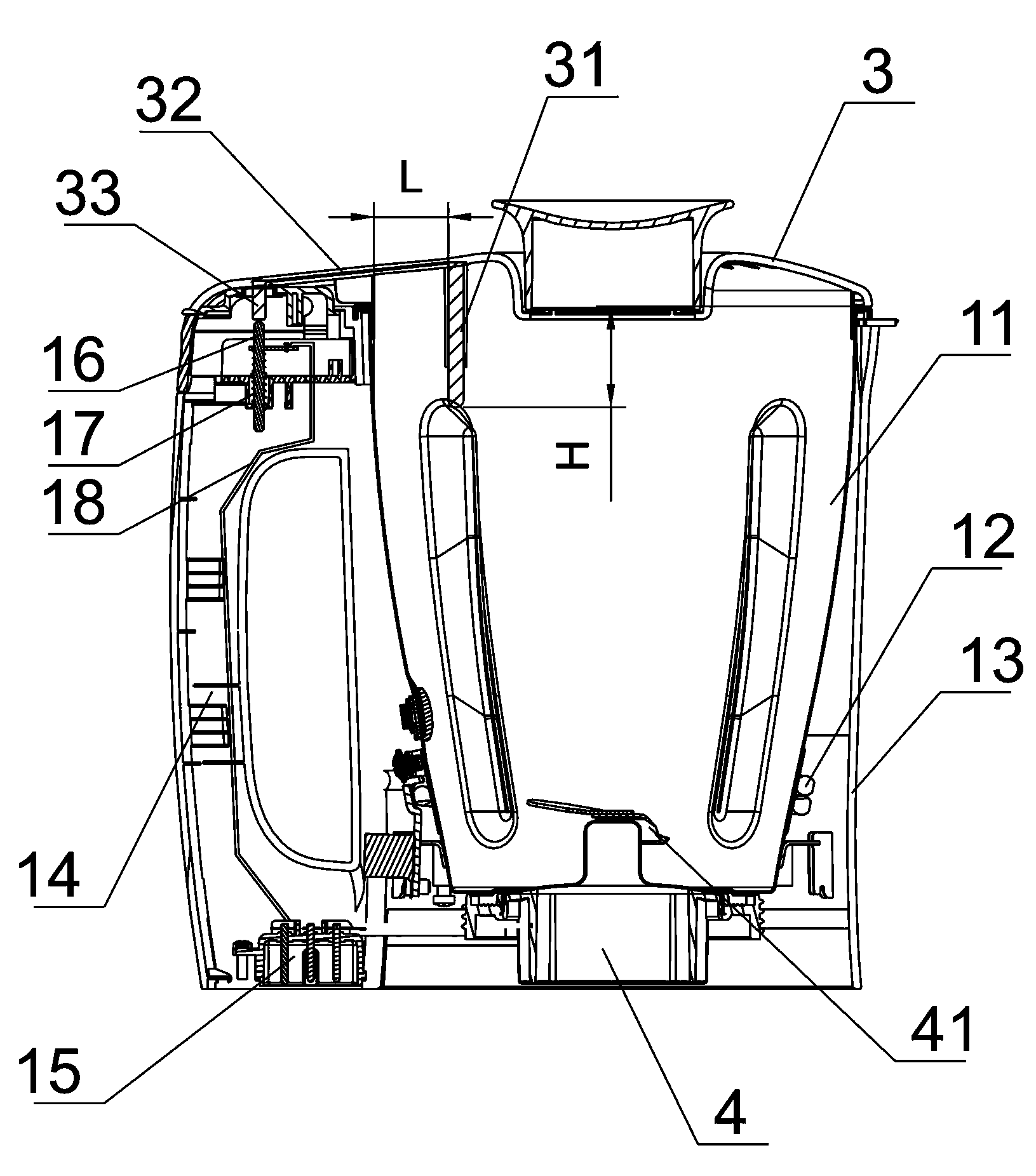

[0044] As the first embodiment of the anti-spill food processor of the present invention, as figure 2 , image 3 As shown, the food processor includes a mixing cup 1 and a machine base 2 . The machine base 2 is provided with a motor and a control unit (not shown in the figure), and the stirring cup 1 is arranged on the machine base 2 . Such as image 3 As shown, the stirring cup 1 includes a cup body 11 , a heating body 12 , an outer cup body 13 , a cup cover 3 and a knife seat 4 . Preferably, the cup body 11 is made of stainless steel, the heating body 12 is arranged around the bottom end of the outer wall of the cup body 11, and the outer cup body 13 covers the cup body 11 and the heating body 12, which can Optionally, the heating body 12 is a heating pipe and extends into the inside of the cup body 11 ; the heating body 12 is a heating plate and is arranged at the bottom of the cup body 11 . The cup cover 3 is fastened on the stirring cup 1, the knife seat 4 is detacha...

Embodiment 2

[0053] As the second embodiment of the anti-spill food processing machine of the present invention, as Figure 7 As shown, the difference from the first embodiment is that one end of the anti-overflow probe 31 is fixed to the cup cover 3 with a screw, the other end is suspended in the air and extends into the inside of the cup body 11, and the conductive ejector rod 33 is screwed Fixed to the cup lid 3 , the conductor 32 conducts the anti-overflow probe 31 and the conductive ejector rod 33 . The cup cover 3 also includes a cover body 34, the cover body 34 closes the fixed end of the anti-overflow probe 31, the conductor 32 and the fixed end of the conductive push rod 33, and the cover body 34 is fixed on the cup by welding. Cover 3.

[0054] Preferably, the cup cover 3 is provided with a groove, and the conductor 32 is arranged in the groove.

[0055] Optionally, the anti-overflow probe 31 and the conductive ejector rod 33 are fixed to the cup cover by riveting, screwing, bu...

Embodiment 3

[0060] As the third embodiment of the anti-overflow food processing machine of the present invention, the difference from the first embodiment is that the anti-overflow device implements wireless transmission with the control unit through an induction coil.

[0061] Such as Figure 8 , Figure 9 As shown, the anti-overflow device includes an anti-overflow probe 31 , a conductor 32 , a signal conversion circuit board 35 , and a first induction coil 361 . The handle 14 is provided with a second induction coil 362 . The first induction coil 361 is disposed at a position corresponding to the cup cover 3 and the second induction coil 362 . The anti-overflow probe 31 passes through the first induction coil 361 , the second induction coil 362 and is finally signal-connected with the control unit.

[0062] The advantage of this arrangement is that the overflow prevention device is connected to the control unit through an induction coil, wireless connection can be realized between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com