Ultrasonic targeted electric flower and fruit thinning machine

A technology of flower thinning and fruit thinning, ultrasonic technology, applied in agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of complex control technology, poor economical use, dependence on light intensity, etc., to ensure work efficiency and improve work efficiency , the effect of a wide range of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

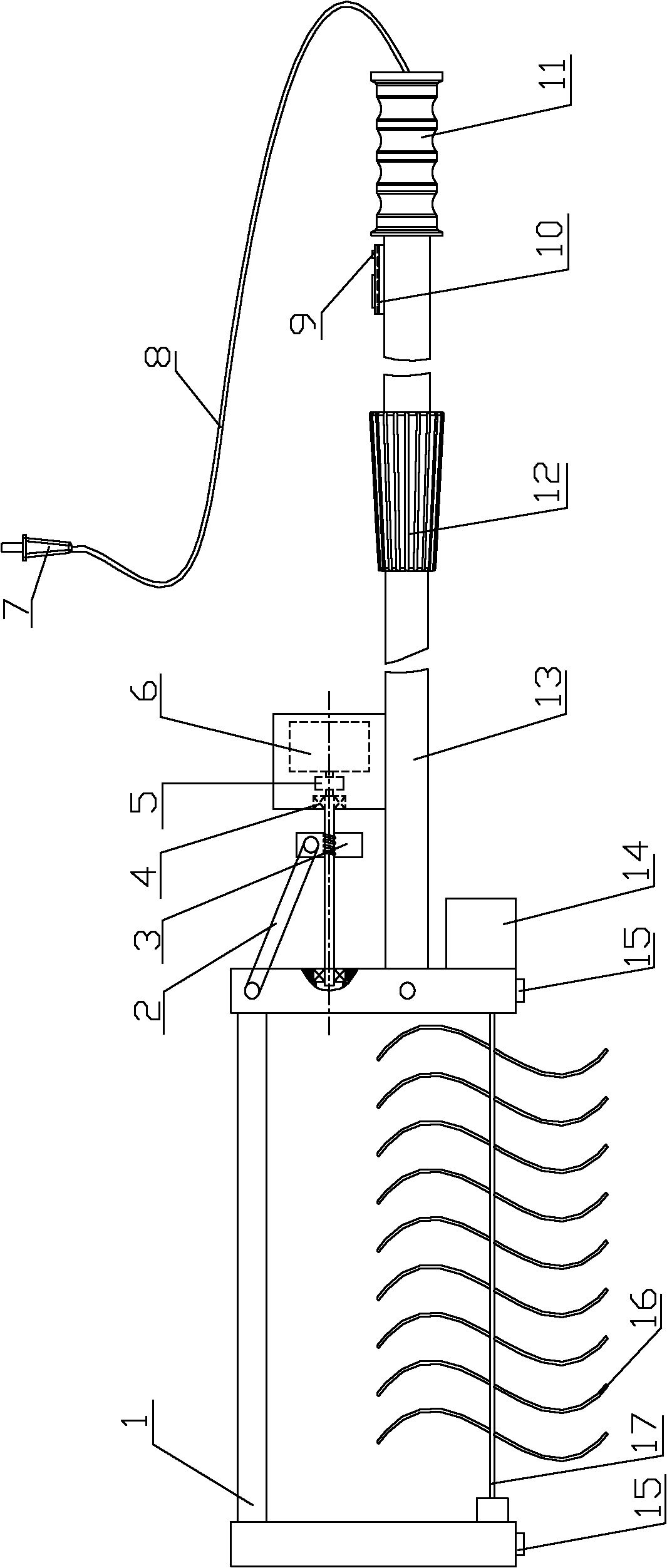

[0041] In this embodiment, an ultrasonic wave-to-target electric flower and fruit thinner has a structure such as figure 1 As shown, it includes a work frame 1, a rotating shaft 17, a flower and fruit thinning adhesive strip group 16, an ultrasonic sensor group 15, a flower and fruit thinning motor 14, an angle adjustment mechanism, a telescopic rod 13 and a control mechanism 10, and the work frame 1 is one side The frame structure of the opening, the opening side of the working frame 1 is provided with a rotating shaft 17, the flower and fruit thinning strip group 16 is arranged on the rotating shaft 17, the flower and fruit thinning motor 14 is arranged at one end of the rotating shaft 17, and the working frame 1 is provided with an ultrasonic sensor group 15 , Angle adjustment mechanism and telescopic link 13 are respectively located on the end face of work frame 1 opening side lower side, and telescopic link 13 one ends are connected with work frame 1, and telescopic link 1...

Embodiment 2

[0060] In this embodiment, an ultrasonic target-targeting electric flower and fruit thinner is compared with Embodiment 1. The difference lies in that the structure of the angle adjustment mechanism is different, such as Figure 10 As shown, the angle adjustment mechanism is a motor-pulley block-spring mechanism, including a spring 23, a pulley block 22, a stay cord 24 and an angle adjustment motor 6, and the two ends of the spring 23 are fixedly connected with the work frame 1 and the telescopic rod 13 respectively, and the pulley block 22 includes two A pulley, two pulleys are respectively located on the work frame 1 and telescopic rod 13, and the stay cord 24 is wound on the rotating shaft of the angle adjustment motor 6 after passing through the two pulleys.

[0061] Wherein, the pulley block 22 is a labor-saving structure design, and the stay rope 24 passes through two pulleys respectively connected with the work frame 1 and the telescopic rod 13, and then winds on the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com