Method for researching sintering performance of iron ore by utilizing mini-sintering test

A technology of sintering test and sintering performance, which is applied in the field of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention is divided into five steps to complete, and the method of the present invention is described in detail in connection with the following embodiments and accompanying drawings:

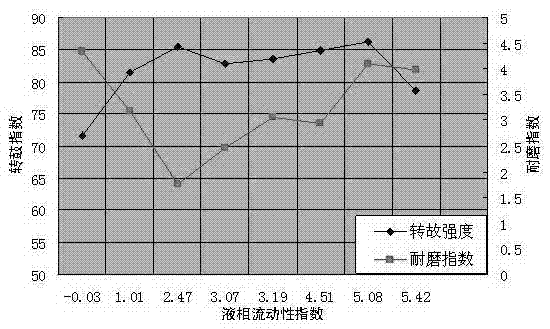

[0020] a. Selection of test raw materials: Select the test iron ore according to the fluidity index of the iron ore liquid phase. The fluidity index of the liquid phase is combined with the ore types used in actual production to select the iron ore for the test according to the law of increasing fluidity index, and the conditions are as follows:

[0021] 1. N>L max -L min , where: N is the number of selected minerals; L max is the maximum liquidity index in the matched mineral; L min It is the minimum liquidity index in the matched ore.

[0022] 2. In L min and L max Within the scope, the liquidity index grades are divided according to equal intervals, and the interval is 0.5 to 1, and each liquidity index grade includes at least one mineral type.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com