Methane nozzle device structure of methane fan heater combustor

A technology for nozzle devices and heaters, applied to gas fuel burners, burners, combustion methods, etc., to achieve the effects of improving the economic benefits of enterprises, avoiding environmental pollution, and saving high-quality energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The details of the present invention will be further described below in conjunction with the accompanying drawings.

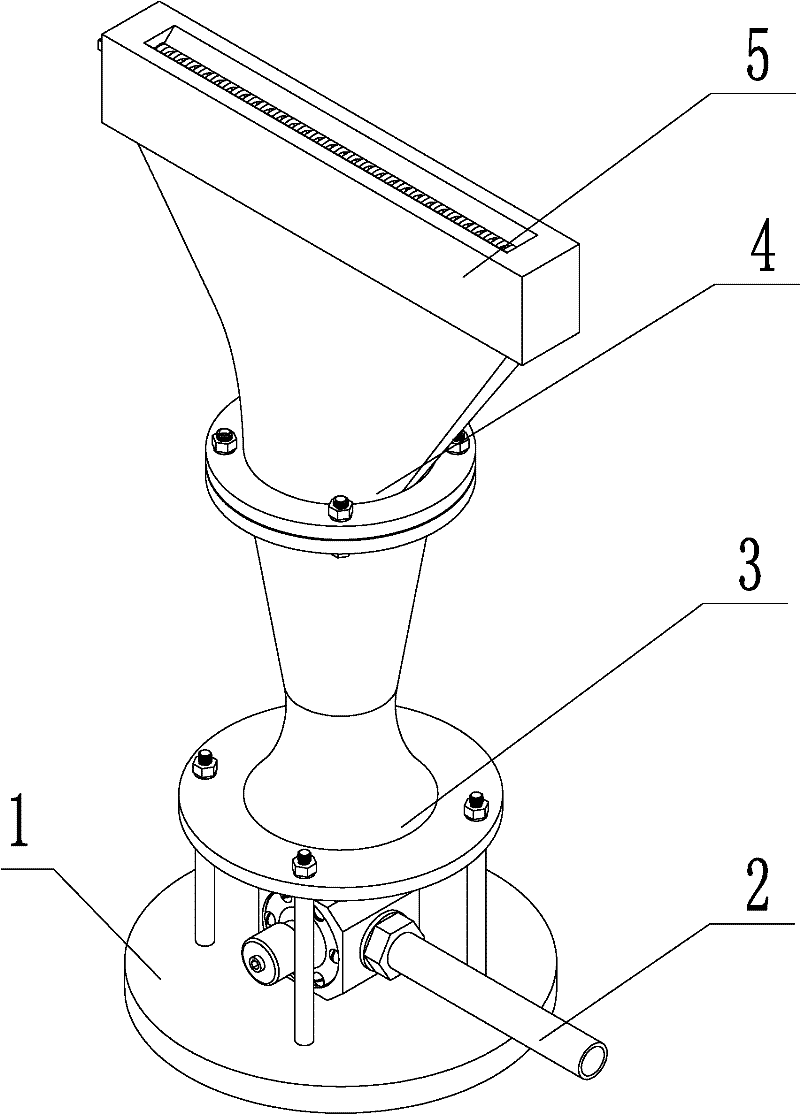

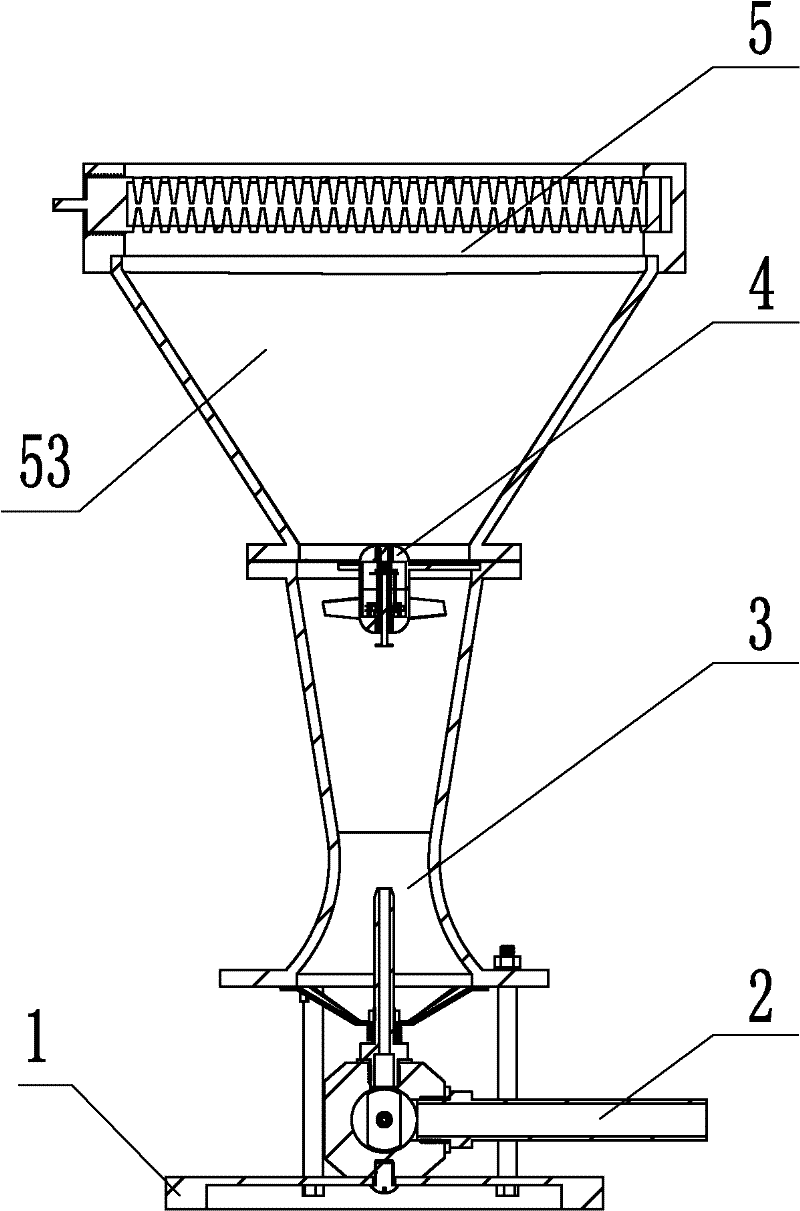

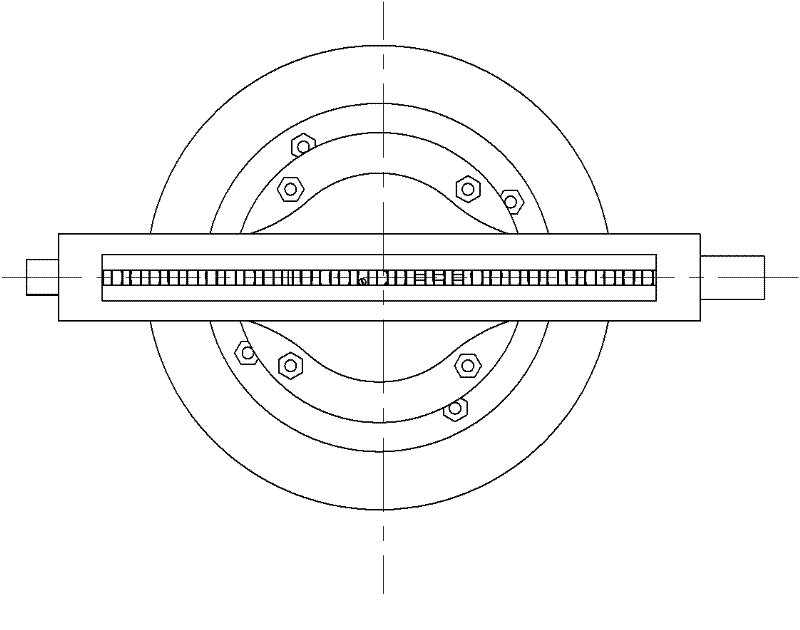

[0049] A biogas nozzle device structure of a biogas heater burner, in which a biogas nozzle device 2, a venturi tube 3, a premixer 4 and a biogas burner port 5 on the top are sequentially arranged on a base 1 from bottom to top, and is characterized in that:

[0050] The structure of the biogas nozzle device 2 is:

[0051] The biogas inlet pipe 24 is horizontally connected to the nozzle base 25;

[0052] The damper regulator 22 is installed between the biogas outlet on the nozzle base 25 and the inlet of the Venturi tube 3;

[0053] The biogas pressure adjustment assembly 23 is arranged in the cylinder hole formed on the nozzle base 25 perpendicular to the plane formed by the biogas ejection pipe 21 and the biogas inlet pipe 24;

[0054] The damper adjuster 22 is composed of several fan-shaped parts whose heights are staggered from each other, and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com