Manufacturing method for macrotype resin letterpress and macrotype resin letterpress obtained by the method

A production method and resin technology, applied in the bonding method by welding, printing plate, printing plate preparation, etc., can solve the problems of helpless printing, narrowing of printing area, etc., and achieve the effect of improving production efficiency and easy injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

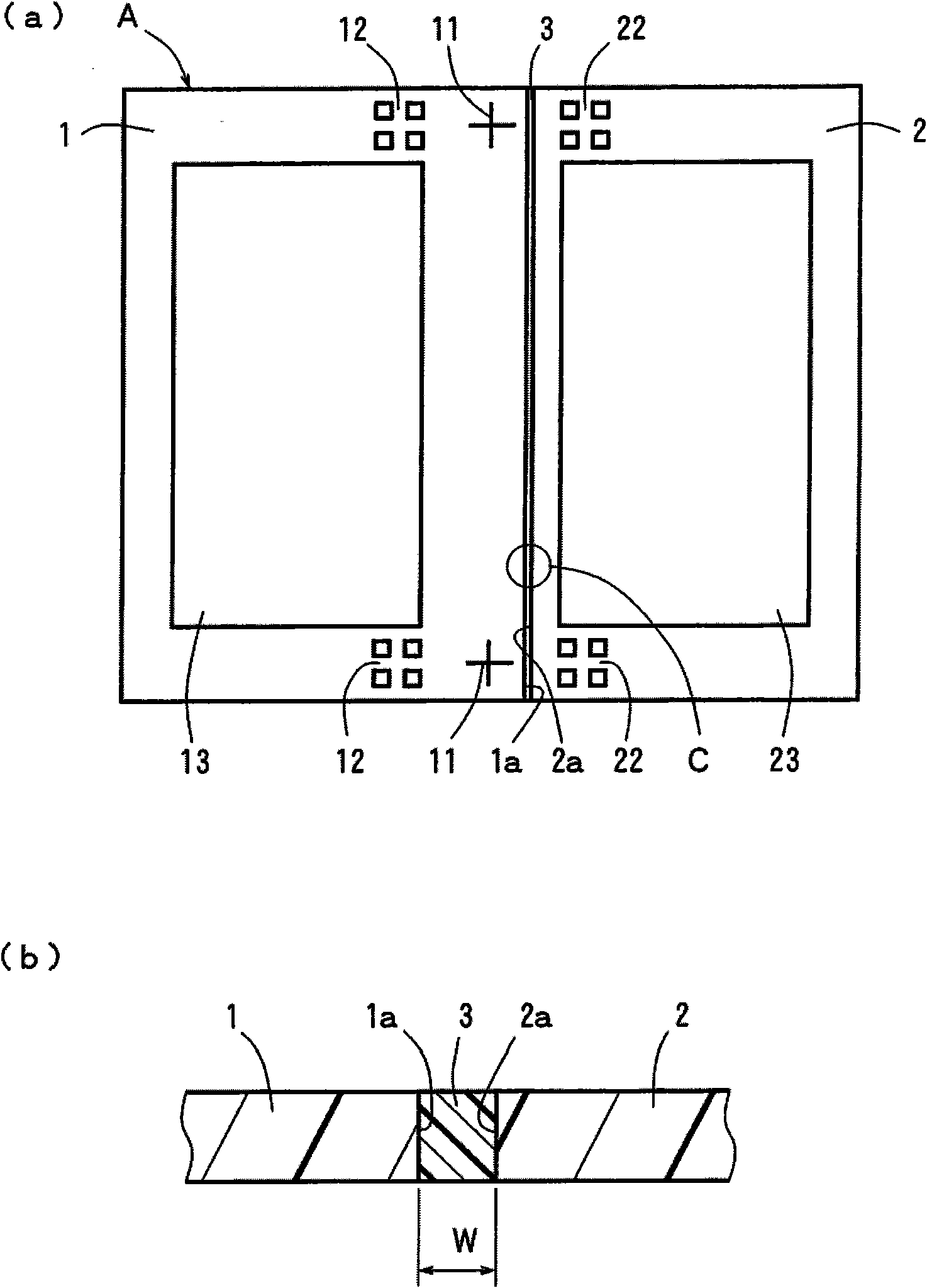

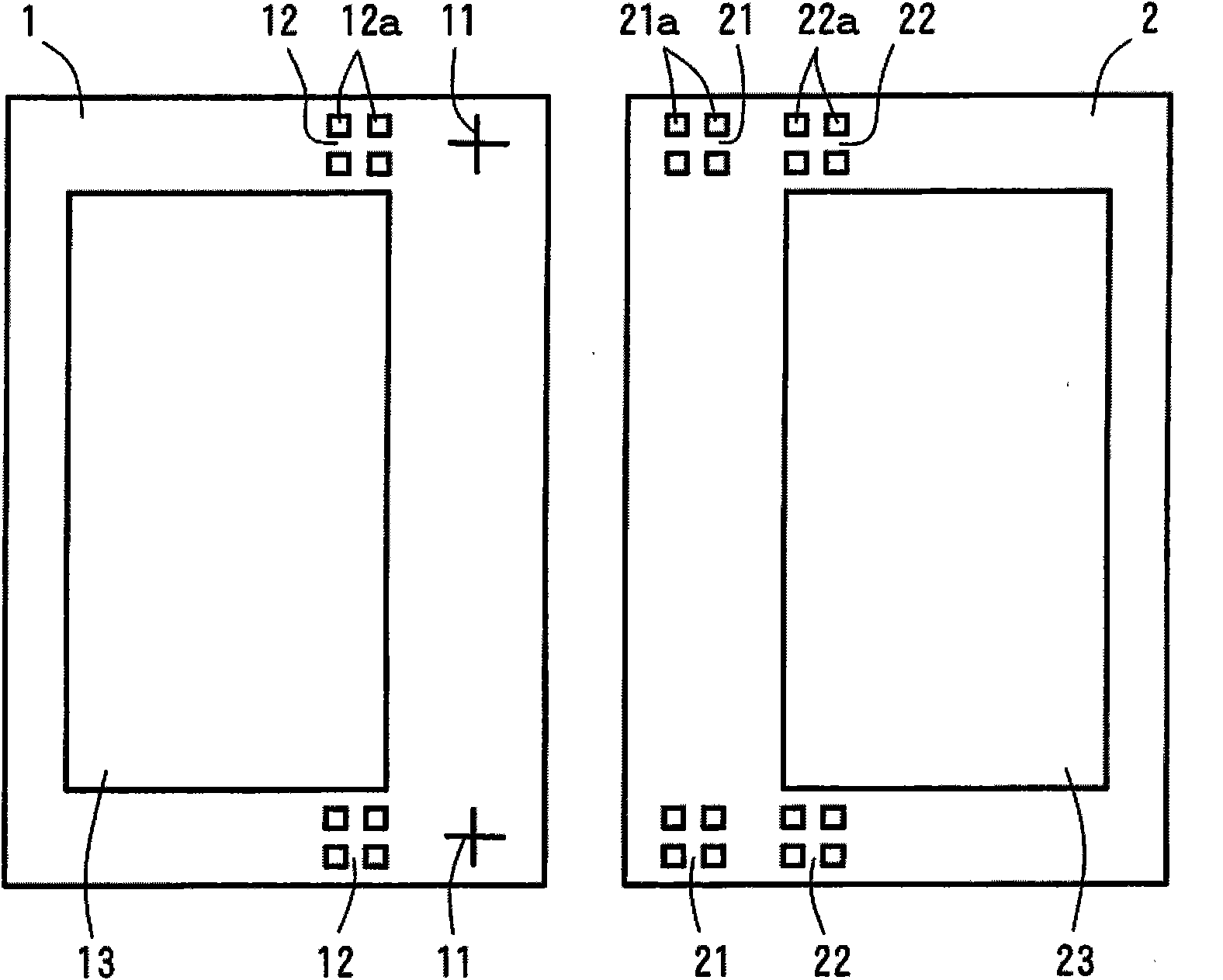

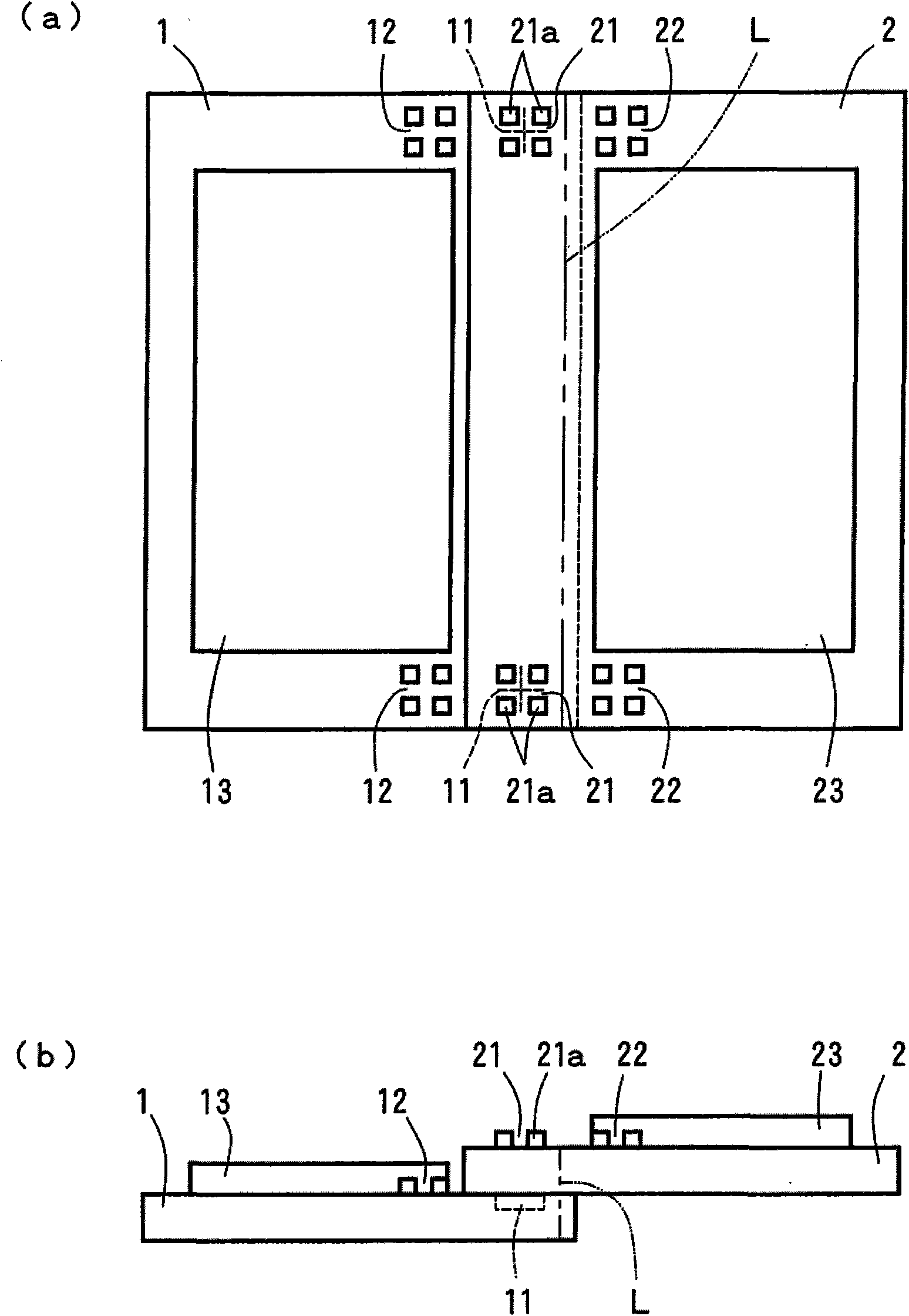

[0046] and Figure 3 ~ Figure 8 The production method shown is the same, and a large resin relief plate is produced by connecting two resin relief plates. In the manufacture of this large-sized resin relief, an alignment sheet having a width of 0.1 mm was used for positioning the resin relief after cutting the edge portion. As a result, in the large resin relief plate manufactured, the space between the opposing side faces in the joining portion was 0.1 mm.

Embodiment 2

[0048] In said Example 1, the sheet|seat for alignment which set the gap between the new side surfaces formed by the said cutting to width 0.8mm was used as the sheet|seat for alignment. Except for this, a large-sized resin relief plate was produced by the same method as in Example 1 above. As a result, in the large resin relief plate manufactured, the space between the opposing side faces in the joining portion was 0.8 mm.

Embodiment 3

[0050] In said Example 1, the sheet|seat for alignment which set the gap between the new side surfaces formed by the said cutting to width 1.8mm was used as the sheet|seat for alignment. Except for this, a large-sized resin relief plate was produced by the same method as in Example 1 above. As a result, in the large resin relief plate produced, the space between the opposing side faces in the joining portion was 1.8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com