Hub lathe jig

A technology of lathe fixtures and hubs, applied in clamping, turning equipment, manufacturing tools, etc., can solve problems such as high equipment costs, rising production costs, and inconvenient clamping, so as to reduce production costs, reduce equipment costs, and ensure machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

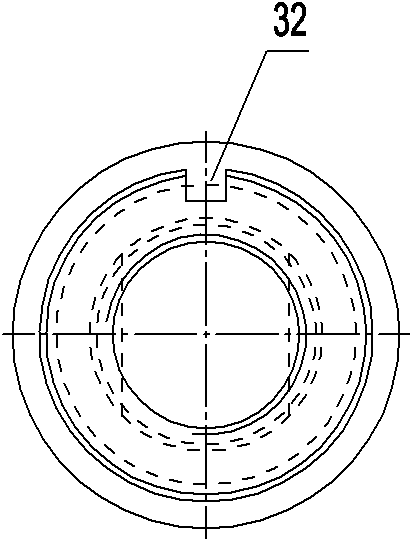

[0023] Such as Figure 1 to Figure 6 As shown, the hub lathe clamp of the present invention includes a positioning disc 1, a clamping slider 3, a support sleeve 4, a tension washer 5 and a pull tube 6, and the positioning disc 1 includes a ) on the main body 11 and one end of the protruding main body 11 is used to locate the positioning part 12 of the hub bearing hole 71, the positioning disc 1 is also provided with a through hole 14 that runs through the main body 11 and the positioning part 12, and the clamping slider 3 includes setting The connecting shaft 33 in the through hole 14 of the positioning disc 1 and the positioning shaft 34 connected to the end of the connecting shaft 33 away from the positioning disc 1, the end of the connecting shaft 33 is recessed inwardly to be provided with a connecting hole 31, and the positioning shaft 34 is close to the end of the free end. The inner depression forms an annular groove 35, and the free end of the positioning shaft 34 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com