Application of polyoxometallate containing Keplerate in carrying out heterogeneous photocatalytic degradation on rhodamine B

A polyoxometalate and heterogeneous catalyst technology, applied in the field of catalysis, can solve the problems of catalyst recovery, separation and recycling difficulties, and achieve the effects of easy raw materials, high catalytic efficiency, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

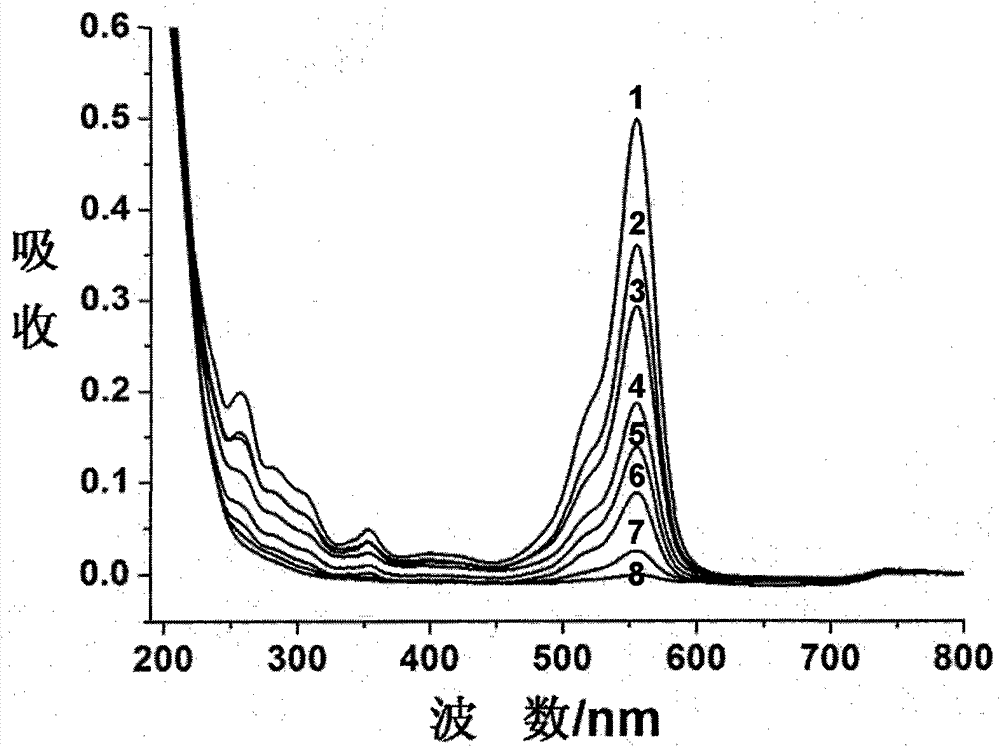

[0015] The nitrogen-containing organic dye rhodamine B is formulated into an aqueous solution to be degraded, with a concentration of 2 mg / L, and the initial pH of the aqueous solution is adjusted to 3, and a tetrabutylammonium salt catalyst of Keplerate type polyoxometalates is added to make the concentration 2 mg / 50 ml. The solution is irradiated under ultraviolet light and stirred rapidly to carry out catalytic degradation. The ultraviolet diagram of its catalytic degradation is shown in figure 1 .

[0016] Within the initial pH3-5 of the solution, the degradation rate and degradation ratio of rhodamine B increased as the pH decreased. The degradation rate reached the highest when the pH was 3.5 and 4.0. When the pH was 3.5, Rhodamine B even degraded to 0 within six hours. At other pH values, the degradation rate could not always reach 100%. Select pH to be 3.5 and 4.0, adjust the amount of catalyst to catalyze, the results show that when the amount of catalyst increases f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com