Feed additive capable of strengthening nutrition and preparation method thereof

A feed additive and nutrition technology, applied in the field of feed additives, can solve the problems of weak nutrient composition, low feed utilization rate, and greater harm to human health, and achieve the effects of reducing diarrhea and improving palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

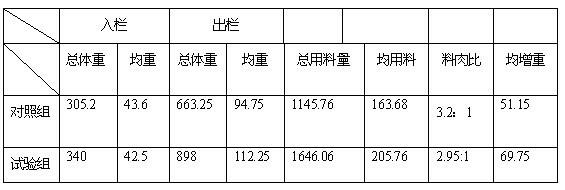

Image

Examples

Embodiment 1

[0014] The weight ratio is: modified soybean lecithin 1.5kg, Bacillus subtilis 1.3kg, fermented soybean meal 2.8kg, wheat flour 0.6kg, skimmed milk powder 0.4kg, whole egg powder 0.4kg, edible calcium carbonate 1.9g, calcium propionate 0.6 kg.

[0015] The production process is as follows: the first component: fermented soybean meal, edible calcium carbonate, and calcium propionate are weighed according to the above ratio, mixed evenly with a mixer, and then pulverized with a micronizer to make 80 mesh for use; the second component: wheat Secondary powder, skimmed milk powder, whole egg powder, and Bacillus subtilis are mixed evenly with a mixer and then set aside; add the first component and the second component into the mixer in proportion, and add it according to the ratio and every minute when the power is turned on. After adding 25% of the modified soybean lecithin, mix it for 4 minutes, and after passing the sampling inspection, pack it into 1.0kg / bag, which is the nutri...

Embodiment 2

[0017] The weight ratio is: 17kg of modified soybean lecithin, 12kg of Bacillus subtilis, 30kg of fermented soybean meal, 6.5kg of wheat flour, 5kg of skimmed milk powder, 4.5kg of whole egg powder, 21g of edible calcium carbonate, and 6kg of calcium propionate. Among them: Bacillus subtilis live bacteria dry powder of Bacillus subtilis selected from Beijing Interlexinuo Biotechnology Co., Ltd.

[0018] The production process is as follows: the first component: fermented soybean meal, edible calcium carbonate, and calcium propionate are weighed according to the above ratio, mixed evenly with a mixer, and then pulverized with a micronizer to make 80 mesh for use; the second component: wheat Secondary powder, skimmed milk powder, whole egg powder, and Bacillus subtilis are mixed evenly with a mixer and then set aside; add the first component and the second component into the mixer in proportion, and add it according to the ratio and every minute when the power is turned on. Add ...

Embodiment 3

[0027] The weight ratio is: 32kg of modified soybean lecithin, 27kg of Bacillus subtilis, 58kg of fermented soybean meal, 11kg of wheat flour, 8kg of skimmed milk powder, 7.6kg of whole egg powder, 37kg of edible calcium carbonate, and 11kg of calcium propionate.

[0028] The production process is as follows: the first component: fermented soybean meal, edible calcium carbonate, and calcium propionate are weighed according to the above ratio, mixed evenly with a mixer, and then pulverized with a micronizer to make 80 mesh for use; the second component: wheat Secondary powder, skimmed milk powder, whole egg powder, and Bacillus subtilis are mixed evenly with a mixer and then set aside; add the first component and the second component into the mixer in proportion, and add it according to the ratio and every minute when the power is turned on. After adding 25% of modified soybean lecithin, mix it for another 4 minutes. After passing the sampling inspection, it is divided into 1.5k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com