Indirect cooling and direct cooling combined electrode water jacket

A technology of cold water jacket and water jacket, which is applied to electric heating devices, electrical components, heating by discharge, etc., can solve the problems of high operating temperature of molybdenum electrodes, oxidation, and poor electrode cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

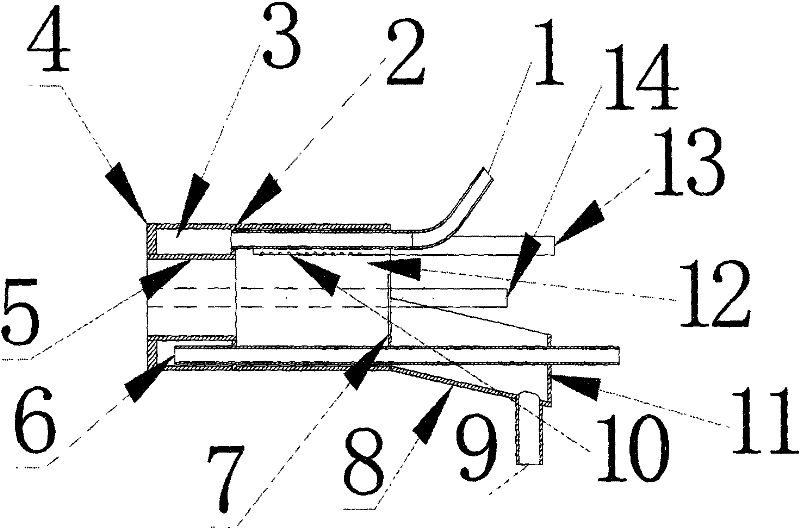

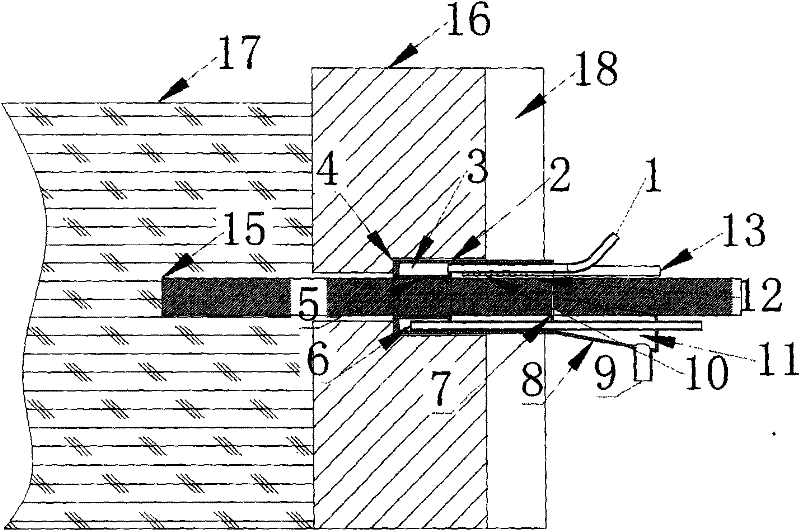

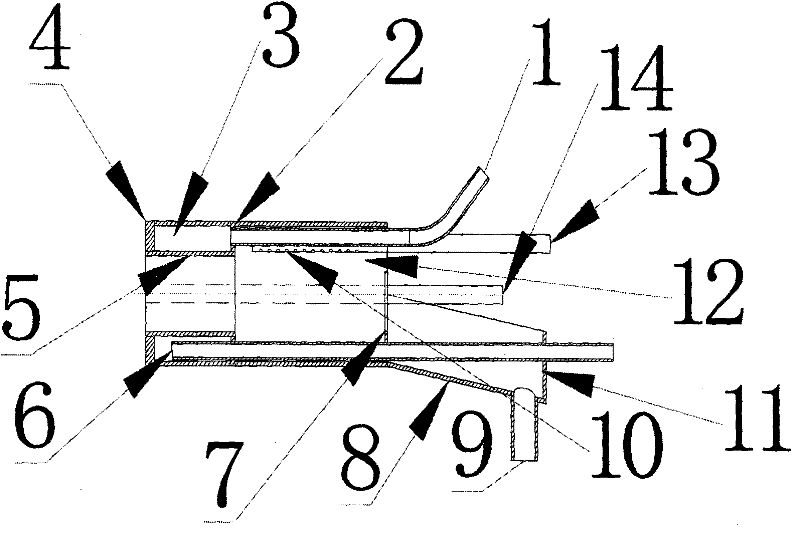

[0013] like figure 1 , figure 2 shown. The present invention consists of a water jacket shell, a direct cold water jacket water inlet pipe 13, a direct cold water jacket water outlet pipe 9, a direct cold water collector 8, a direct cold water jacket baffle 7, a temperature measuring device 14, an indirect cooling chamber rear baffle 2, an indirect cooling chamber The front baffle plate 4 of the cooling chamber, the inner wall pipe 5 of the indirect cooling chamber, the water outlet 1 of the intermediate cold water jacket and the water inlet pipe 6 of the intermediate cold water jacket are composed. Among them, the water jacket shell, the direct cold water jacket inlet pipe 13, the straight cold water jacket outlet pipe 9, the straight cold water collector 8, the collector baffle 11, the straight cold water jacket baffle 7, and the temperature measuring device 14 constitute the direct cooling water jacket . The inner cavity of the water jacket shell of the direct cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com