Oblate coiling aluminum die

An oblate and winding technology, which is applied in coil manufacturing and other directions, can solve problems such as the inability to guarantee the quality of winding and the easy deformation of wooden molds, etc., and achieve the effects of reducing production technical requirements, reducing production costs, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

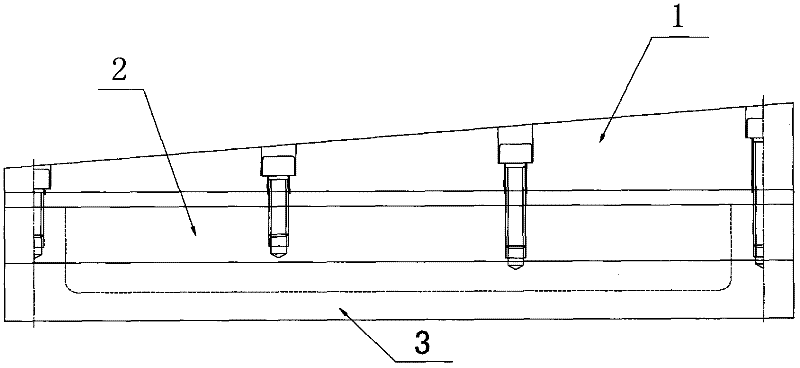

[0012] Such as figure 1 and figure 2 An oblate winding aluminum mold is shown, including a semi-cylindrical half-petal mandrel 3, a core strip 2 is arranged in the middle of the half-petal mandrel 3, and the middle plane of the half-petal mandrel 3 is along the axial direction Two oblique bars 1 are provided. The inclined strip 1 is installed on the edge of the half-valve mandrel 3, and the inclined sides are installed in the same direction.

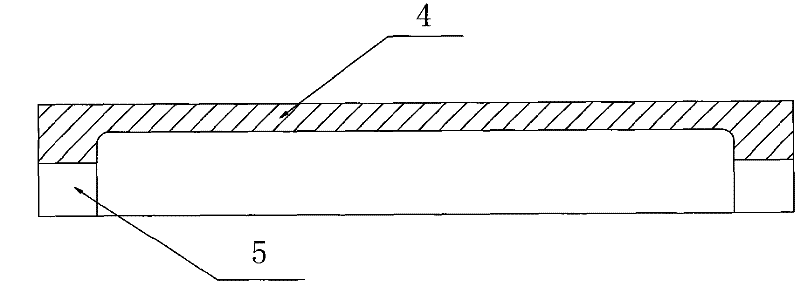

[0013] Such as image 3 The half-petal mandrel shown is a semi-cylindrical shell 4, and grooves 5 for placing core strips 2 are respectively provided at the positions of the middle axes at both ends of the half-petal mandrel 3.

[0014] In the process of production and use, three kinds of parts are first poured according to the size, and then processed by cutting, grinding, polishing and other processes respectively. Finally, these parts are connected with bolts, and two identical aluminum molds are used together to form a flat roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com