On-line detection device for broken wires of wire ropes

A technology of wire rope and broken wire, applied in the direction of material magnetic variable, etc., can solve the problems of undetectable wire rope and weak magnetic flux leakage signal, and achieve the effects of accurate detection, high sensitivity and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

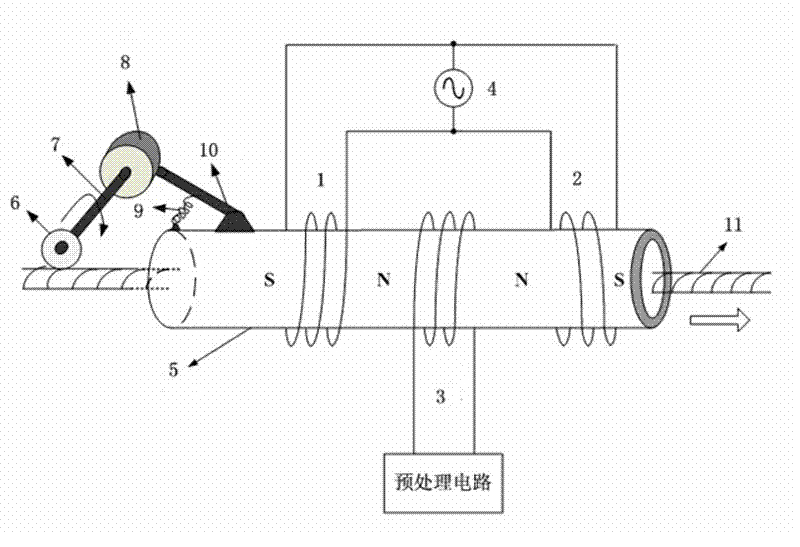

[0014] The specific embodiment of the present invention is further described in detail in conjunction with the accompanying drawings, so that technical personnel in this field can actually make a kind of magnetic induction wire rope broken wire online detection device according to this specific embodiment, and its specific embodiment is as follows:

[0015] figure 1 As shown, for the broken wire signal sensing unit of the present invention, in actual implementation, the unit, that is, an inert tube with three coil windings, should be placed on the steel wire rope 11 to be tested and fixed. The detailed manufacturing process of the broken wire signal sensing unit: on a magnetically inert (such as copper or aluminum) tube 5 with a length of L and a diameter of D, three groups of coils are wound with an enamelled copper wire with a diameter of d, and the two ends of the tube 5 The number of turns of the first induction coil 1 and the second induction coil 2 are equal, both are N1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com