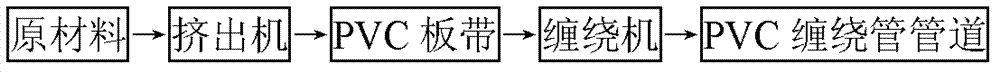

U-PVC (Unplasticized Polyvinyl Chloride) steel band spiral pipe and preparation method thereof

A technology of winding pipes and steel strips, which is applied to pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high cost and large material consumption, and achieve the effects of low cost, high displacement resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

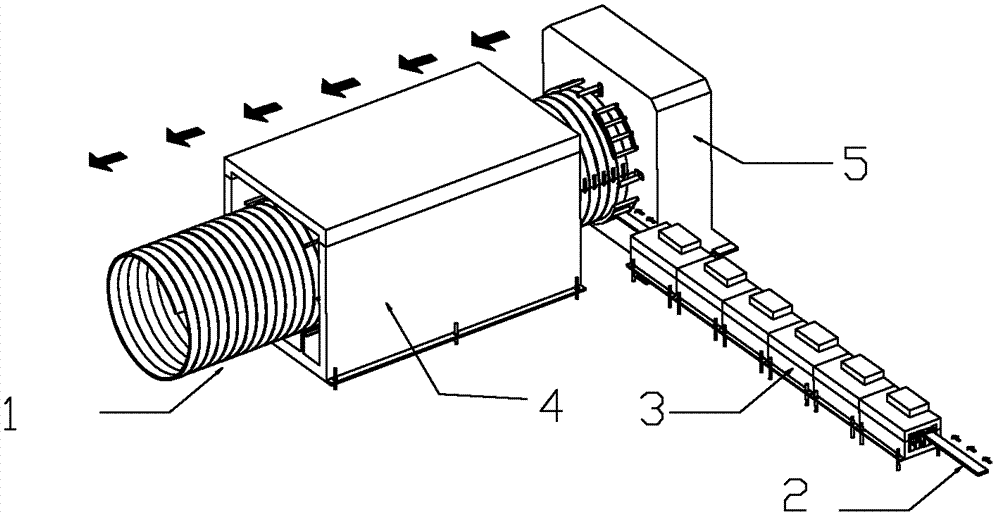

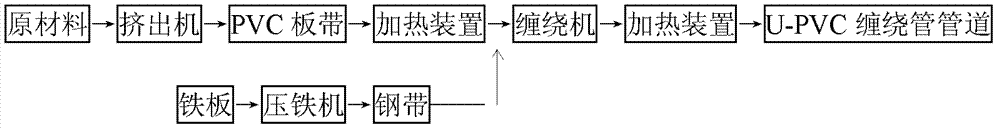

[0027] First, the U-PVC material is extruded through an extruder with a cross-section such as Figure 4 , 5 The U-PVC strip 6 shown includes a base plate 61 and an upper cover plate 62, and then the U-PVC strip 6 is heated by a tunnel heater for about 2 minutes, so that the temperature of the U-PVC strip 6 reaches 85° C. And keep the temperature, and the steel belt 7 is input into the winding forming machine for winding to form a U-PVC pipe.

Embodiment 2

[0029] First, the U-PVC material is extruded through an extruder with a cross-section such as Figure 4 , 5 The U-PVC strip 6 shown, including the base plate 61 and the upper cover plate 62, is fed into the winding forming machine together with the steel strip 7 for winding to form a U-PVC pipe, and then the formed U-PVC winding pipe 1 is passed through a tunnel type The heater is heated for about 2 minutes, so that the pipe temperature reaches 75°C.

Embodiment 3

[0031] Firstly, the PVC material is extruded through the extruder with a cross-section such as Figure 4 , 5 The U-PVC strip 6 shown includes a base plate 61 and an upper cover plate 62, and then the U-PVC strip 6 is heated for about 1 minute by a tunnel heater, so that the temperature of the U-PVC strip 6 reaches 55° C. And keep the temperature, and the steel belt 7 is fed into the winding forming machine for winding to form a U-PVC pipe, and then the pipe is heated by the tunnel heater 4 for about 3 minutes, so that the temperature of the pipe reaches 100°C.

[0032] The U-PVC material in the present invention has lower cost and higher hardness than the currently commonly used PE material. In the case of achieving the same performance, the PVC winding pipe with steel belt saves 30% to 60% of PVC material and reduces the cost by 20% to 50% compared with the existing pure PVC winding pipe, which is of great significance for practical application.

[0033] Take pipe ring stif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com