Severe plastic deformation method for grain refinement

A technology for large plastic deformation and grain refinement, which is applied in the field of large plastic deformation processing for the preparation of ultra-fine grained materials, can solve the problems of reducing large plastic deformation, limited material size, and low life, and achieves uniform grain refinement, Ease of industrial application, the effect of expanding the range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

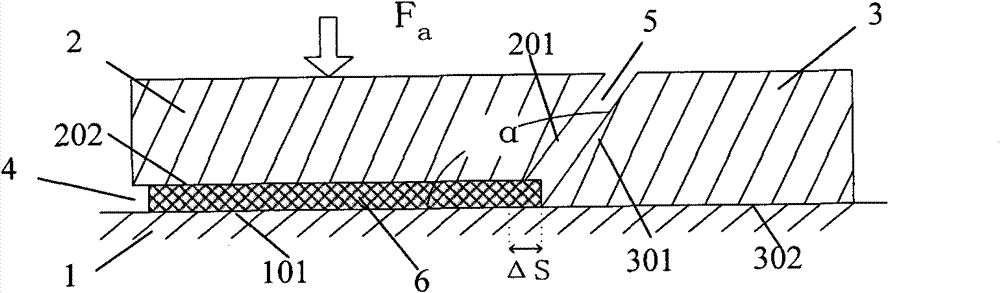

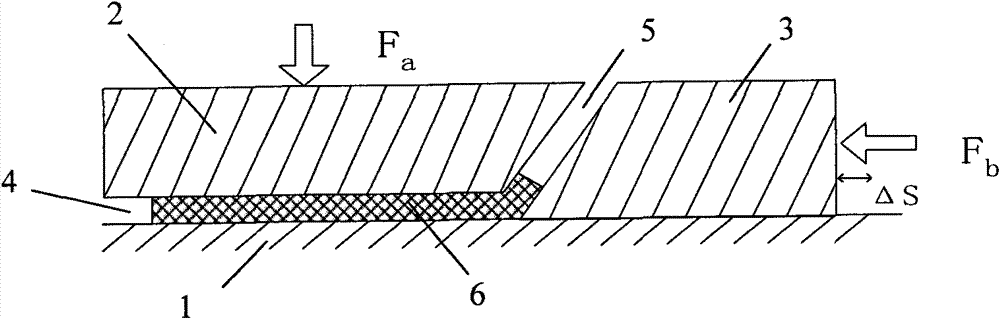

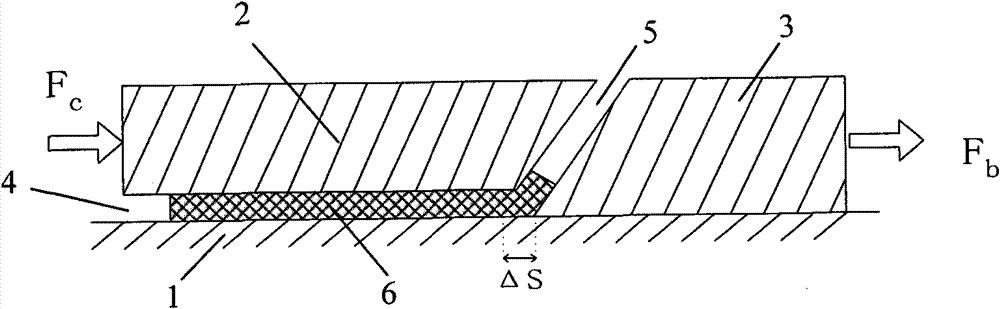

[0032] The present invention will be further described by taking the following preparation of ultra-fine grain IF steel plate as an example.

[0033] see Figure 1 ~ Figure 4 , the large plastic deformation extrusion channel used in the present invention adopts three modules 1, 2, 3, wherein the first module 1 is located below, its working surface 101 is a plane, and the second module 2 is located on the working surface of the first module 1 101 above, keep a gap with the working surface 101 of the first module 1 to form the first channel 4; the front end surface 201 of the second module 2 is a slope; the third module 3 is set on the working surface of the first module 1 101, located on the side of the slope 201 of the second module 2, the side 301 of the third module 3 opposite to the slope 201 of the second module 2 is also a slope, and maintains a gap with the slope 201 of the second module 2, forming Second channel 5.

[0034] The contact surfaces of the first module 1 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com