Connector removing jig and connector removing method using the same

A technology for connectors and unclamping, which is applied to the parts of the connecting device, the connection/disconnection of the connecting device, and the connection, etc., which can solve problems such as difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

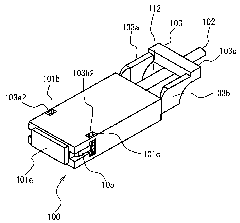

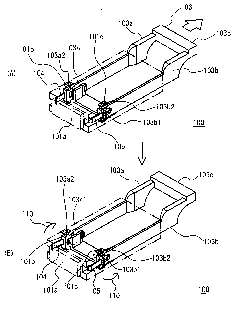

[0029] First, for ease of understanding Figure 7 The pull-off jig 1 of the present embodiment described in, refer to Figure 1 to Figure 5 The cable-side connector 100 that can be detached by the detachment jig 1 will be described.

[0030] figure 1 It is a perspective view of the board-side connector 50 and the cable-side connector 100 . figure 2 for following with figure 1 A perspective view of the cable-side connector 100 viewed from a different side. image 3 It is a perspective view of the inside of the cable-side connector 100 . image 3 (A) is a figure which shows the state which the 1st engaging claw 104 and the 2nd engaging claw 105 are closed, image 3 (B) is a figure which shows the state which the 1st engaging claw 104 and the 2nd engaging claw 105 opened. Figure 4 for following with image 3 A perspective view of the interior of the cable-side connector 100 viewed from a different side. Figure 4 (A) is a figure which shows the state which the 1st engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com