Method for evaluating corrosion fatigue damage

An evaluation method and technology for corrosion fatigue, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem of inability to reproduce the correct state, and achieve the effect of improving reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

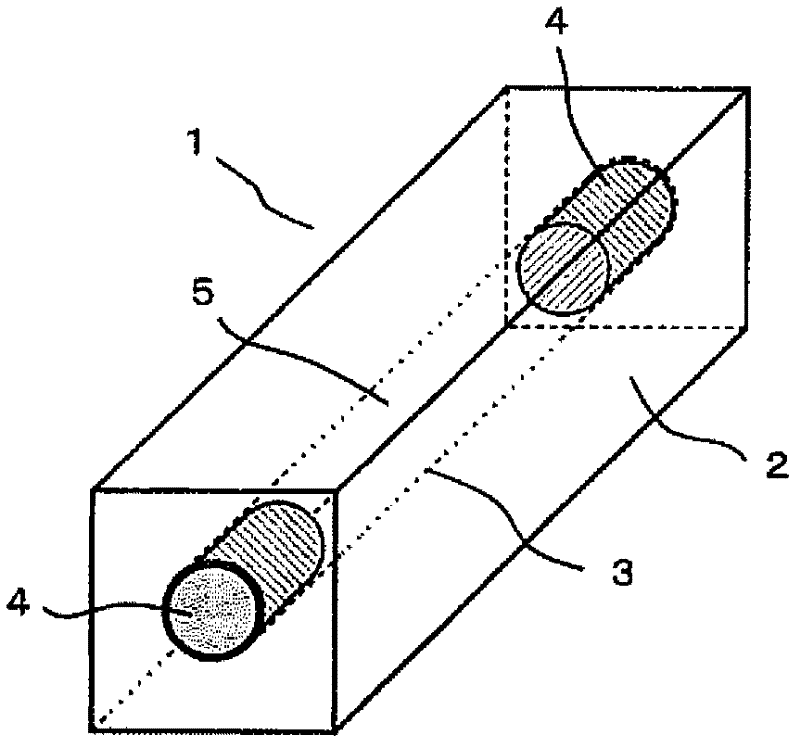

[0039] figure 1 It is a schematic diagram showing an example of a test piece used in the evaluation method of the present invention. It is used to reproduce and evaluate the corrosion fatigue damage that can occur in the internal cooling hole of the actual die casting metal mold. The test piece 1 is formed by sealing the following corrosive medium 5 inside the space 3 of the raw material piece 2 by means of the plugs 4 at both ends. The size of the raw material sheet 2 is 15 mm square x 60 mmL, and a through hole with a diameter of about 10 mm is formed at the center of the 15 mm square in the L direction. In addition, the material of the raw material sheet 2 is the same as that of the actual die-casting mold assumed in this embodiment, and SKD61 is quenched at 1030°C and tempered to 45HRC. The space 3 of the raw material sheet 2 is equivalent to the internal cooling hole of the actual die-casting metal mold, and the corrosion medium 5 as a simulated cooling medium is sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com