Rotary die bonding apparatus and methodology thereof

A chip combination and rotary technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as low production volume and the influence of production capacity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by one skilled in the art or by one of ordinary skill in the art that the invention may be practiced without these details. In other instances, well-known methods, procedures and / or elements have not been described in detail so as not to obscure the present invention.

[0029] The invention will be understood more clearly from the following description of embodiments thereof, which are given by way of example only with reference to the accompanying drawings, which are not drawn to scale.

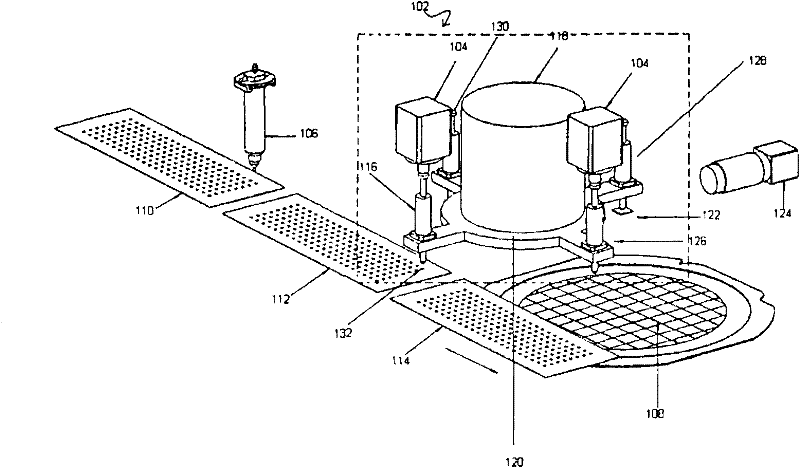

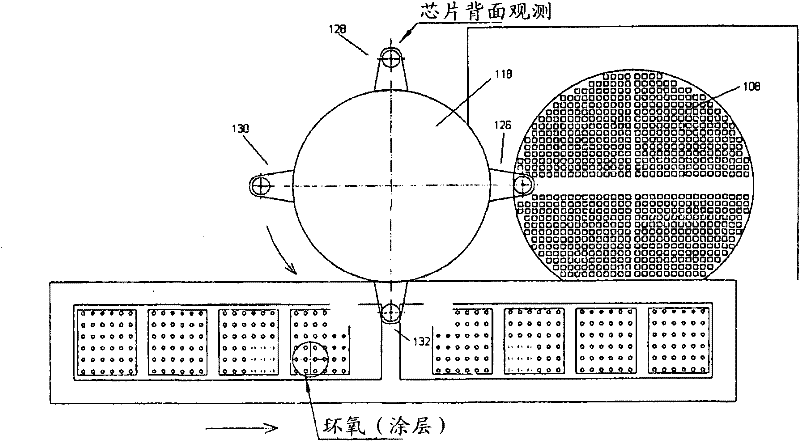

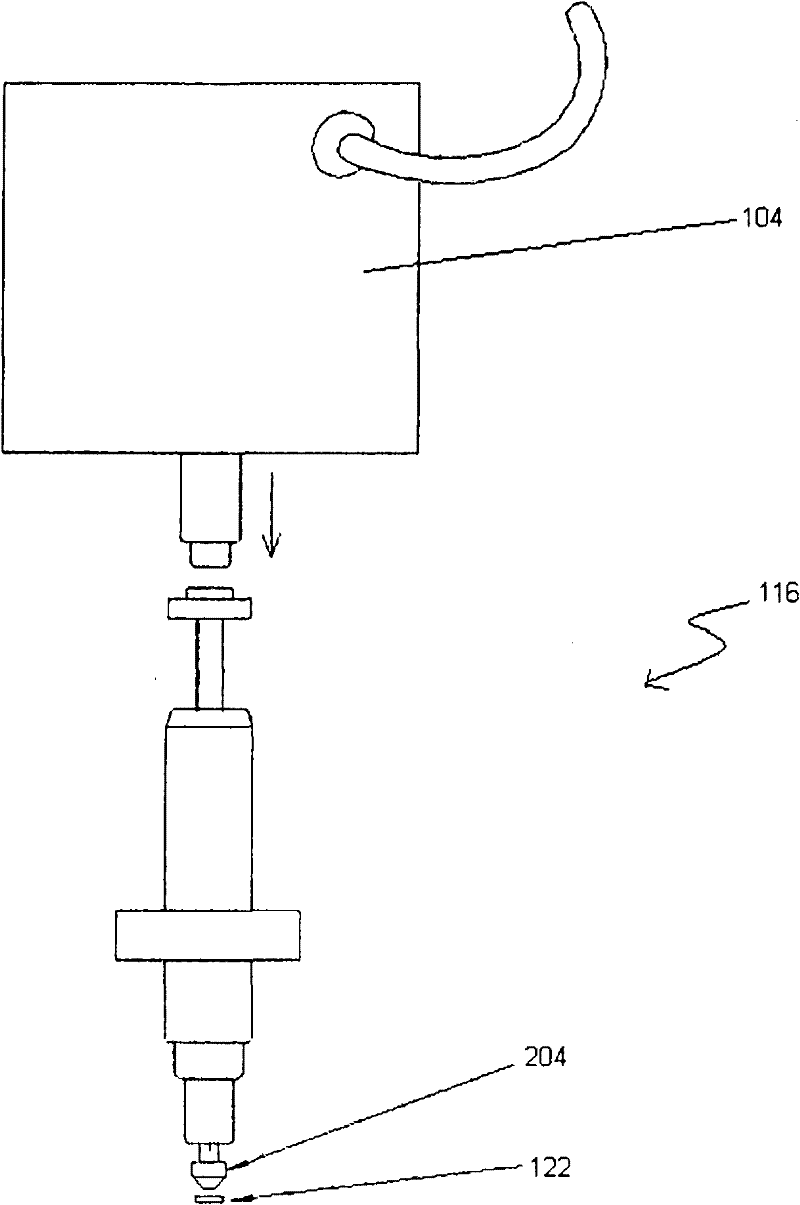

[0030] refer to figure 1 , showing a perspective view of the rotary die bonding apparatus 102 together with the image capture apparatus 124, the epoxy syringe 106, the die wafer ring 108, and the lead frames 112, 114; further illustrated by figure 2 Concrete, the figure 2 A top view of the rotary die b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com