Pneumatic full-automatic pocket patching machine

The technology of a pneumatic bag sticking machine is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., which can solve the problems of rising manufacturing cost and limited promotion, and achieve low manufacturing cost, high transmission accuracy and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

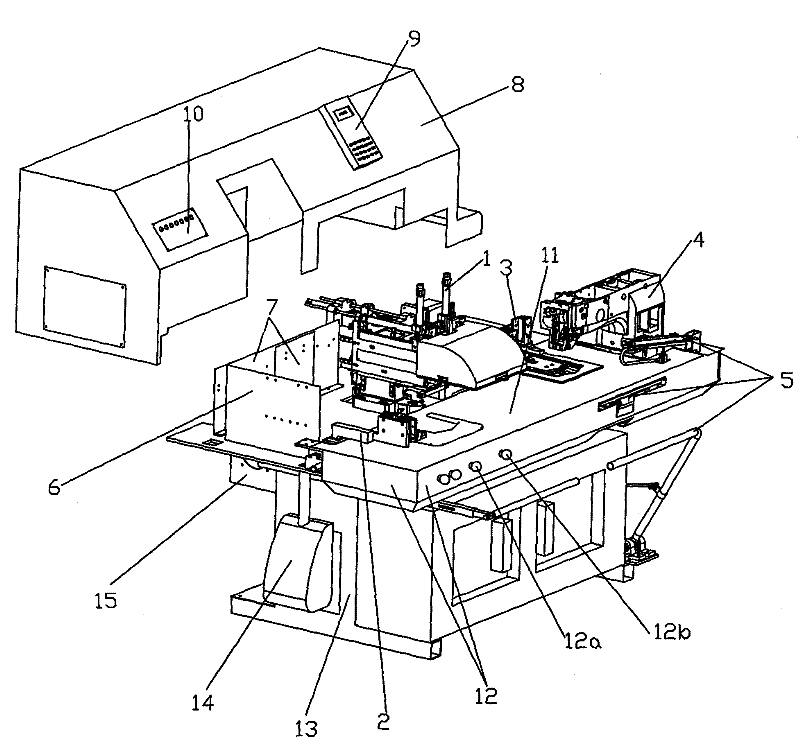

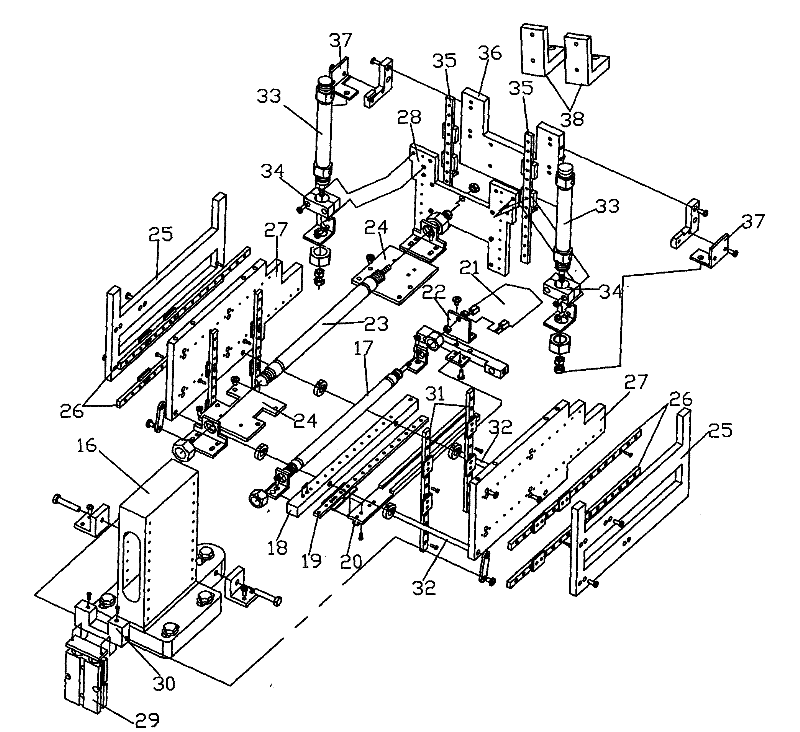

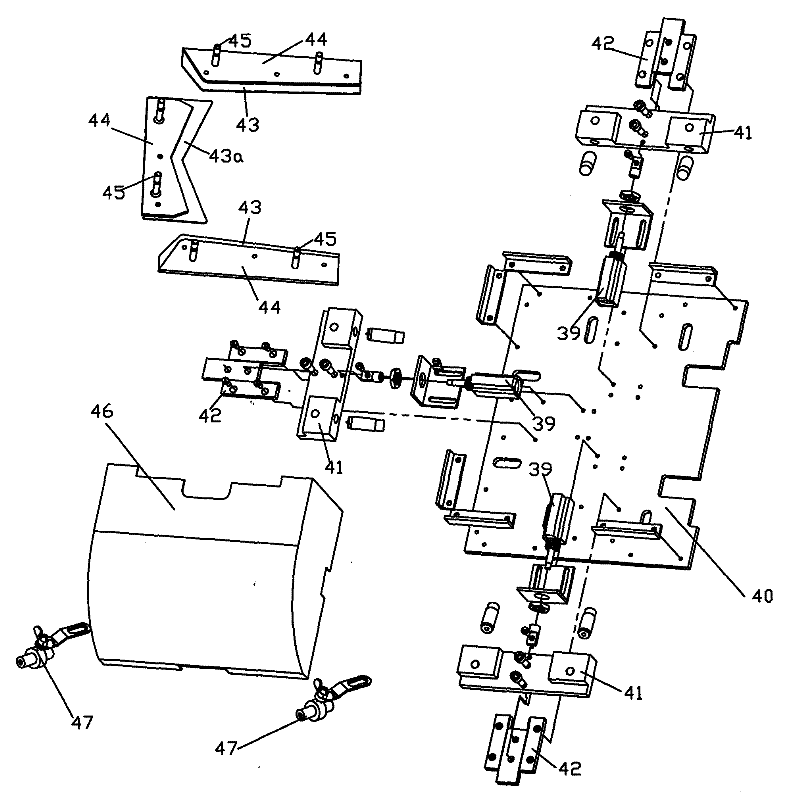

[0019] like figure 1 As shown, the pneumatic fully automatic bagging machine of the present invention includes a frame steel plate, a pneumatic automatic iron-free folding mechanism 1, a pneumatic automatic feeding mechanism 2, a coordinate pattern transmission mechanism 3, and a rotary shuttle pattern machine sewing head 4 , Pneumatic automatic feeding mechanism 5, air pressure adjustment mounting plate 6, solenoid valve mounting plate 7, protective cover 8, control display plate 9, quick change mechanism control plate 10, stainless steel work table 11, stainless steel enclosure 12, frame 13 , vacuum cleaner 14 and electrical control box 15, the pneumatic automatic non-ironing hemming mechanism 1 is arranged on the top of the back of the frame steel plate, and the pneumatic automatic feeding mechanism 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com