Thin-wall part processing clamping device and clamping detection method

A thin-walled part processing and clamping device technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc. Fast processing, simple and fast clamping, and the effect of reducing clamping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical scheme and technical purpose of the present invention easier to understand, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments:

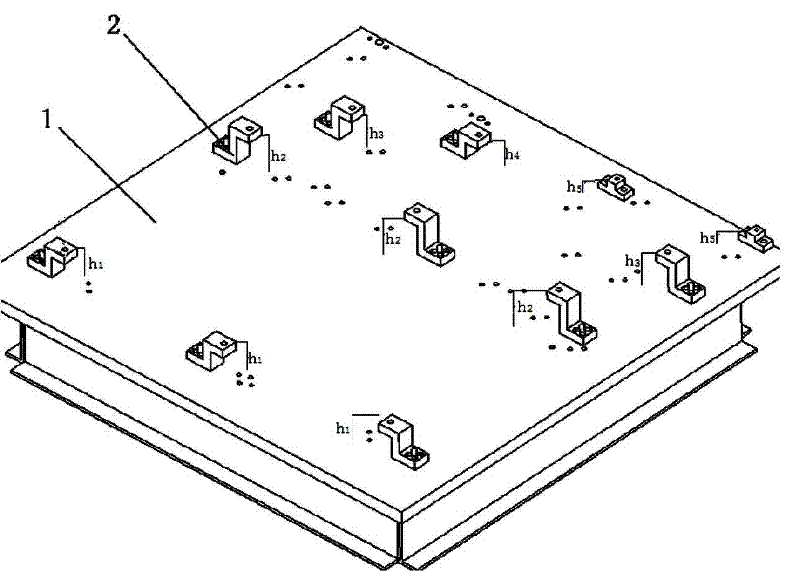

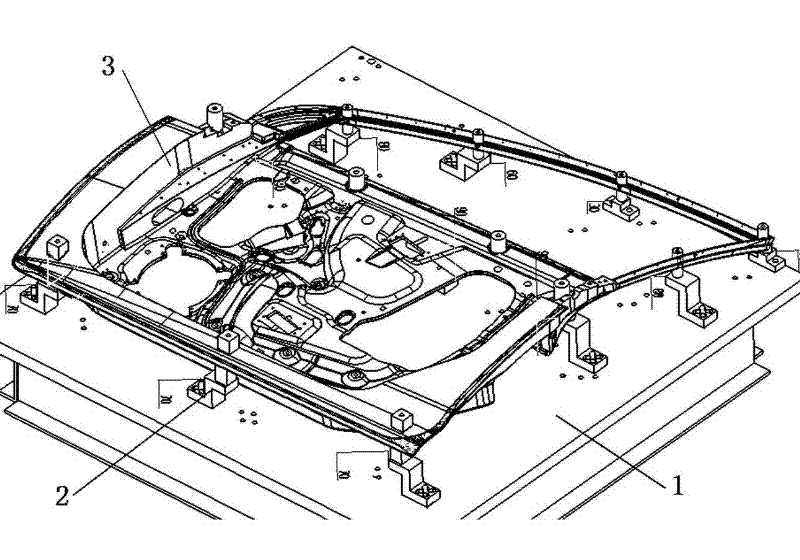

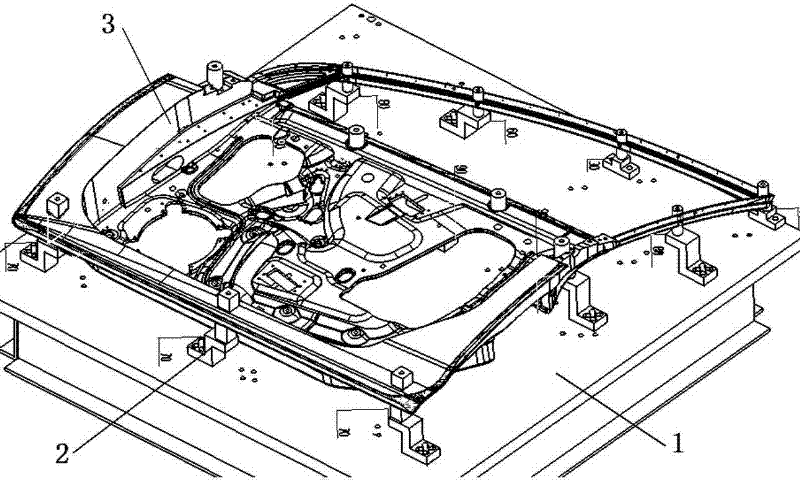

[0018] As shown in the figure, a clamping device for processing thin-walled parts includes a bottom plate 1 and a positioning bracket 2. It is characterized in that: the positioning bracket 2 is in the shape of a "Z", and the bottom end of the positioning bracket 2 It is fixed on the bottom plate 1 by bolts, and the upper end of the "Z" shape of the positioning bracket 2 is provided with a positioning hole for fixing the thin-wall part processing module 3 .

[0019] A thin-walled part processing and clamping method for the above-mentioned thin-walled part processing and clamping device, characterized in that it comprises the following steps:

[0020] Clamping:

[0021] a). Reserve support columns on the thin-walled parts processing modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com